If you have ever looked forward to an event with great anticipation, waited patiently for it to arrive, and found it to be even more exciting than your wildest expectations…you can understand exactly how we felt last week. The Inside 3D Printing show in Seoul was just such an event. Held this past Thursday and Friday at the Kintex Convention Center in Seoul, South Korea, the show’s attendance and levels of energy exceeded everyone’s expectations. Those readers who have followed our reports from South Korea know that 3D printing has been slow to catch on here, but it now appears that having caught on; we can expect to see a lot of exciting activity coming out of East Asia in the very near future.

Day 1

We arrived Thursday morning just before 09:00am, just in time to hear the opening keynote speech by Daniel Thompson, General Manager of Stratasys, Korea Ltd. Mr. Thompson spoke about how the future of 3D printing is here right now and how with the technology, companies can bring a plethora of innovative and customized, as well as customizable, products to the world. He even showed a pair of Nike running shoes he had customized for himself, made specifically for the Seoul Inside 3D Printing show. Outside in the main exhibition hall, exhibitors hurriedly arrived and began setting up their booths in anticipation of the crowds of visitors that were expected. By the opening of the show some 5,000 visitors had already pre-registered for admittance, so these preparations were not without good cause.

During the break following Mr. Thompson’s opening address, we went out onto the exhibition floor and were amazed at the number of people massed. Being South Korea, large crowds are not unusual, but this was impressive even by Korean standards. Grabbing a cup of coffee, we met (or should I say, found, by virtue of the crowd around him) one of those show attendees that sometimes makes as big a splash as the registered exhibitors.

Abdullah Alhussainan is the General Manager for a company called Innovative Engineering from Kuwait and he was drawing quite a bit of attention wearing a bright red pair of Google Glass glasses. The reason for his popularity was that he was very gracious, indulging many fellow attendees by allowing them to try on the Glass briefly and answering questions about it. He had come all the way from Kuwait to see the show, and said he brought the Glass mostly to record video and take photos. He did occasionally use it to access the internet, but that doing so “really kills the battery.”

Going back into the conference hall, we were just in time to see Mr. Park Yoon Kyu, Chief of the Information and Communication Technology (ICT) Industry Division of the South Korean Ministry of Science, ICT and Future Planning. Korea has traditionally taken a very “top down” approach to business development, and we were curious to see how they planned on dealing with this new technology.

Mr. Park started by admitting that South Korea was a “bit” behind in the 3D arena, but that the Korean government was committed to rectifying this. He outlined the official plans to build an infrastructure and educate the people necessary to allow Korea to contribute to, and compete in, the 3D printing marketplace. Specifically, he said that by this fall the government would be opening several educational centers to train business leaders and teachers in this new technology and provide appropriate curricula to universities and public schools to help educate succeeding generations. He also mentioned that by 2016, some 1,600 Korean public schools would be provided with 3D printers for student use, though he didn’t specify what type of printer, or who would be providing them.

Next he said that the government is working on creating a database/portal system to allow the dissemination and sharing of government owned 3D content, though he again did not elaborate. The biggest announcement for the 3D world at large may have been his statement that the Korean government would be focusing on 3D software development. He said that they would first be looking at medical applications, especially for plastic surgery, and then move on from there. He also noted the Korean government’s dedication to the creation of new laws designed to facilitate the protection of Intellectual Property.

We then had our morning break, and again we were out on the exhibit hall floor. One of my favorite parts of such conventions is all the little freebies given away by the vendors, so we rushed about collecting what trinkets we could before they were all gone…and with the crowds there, that didn’t take long. Unfortunately, not being able to be in two places at once, we had to forgo the speakers over in the Maker Summit, where Bradley Isnard spoke about high performance 3D textiles and Emma Kwon discussed 3D printing technologies for consumer applications. Back into the presentation hall we went for the next speaker.

Isaac Katz, a fashion and jewellery designer and entrepreneur from Mexico City, Mexico was up next. He spoke about the “immorality of retail” and noted that there would always be some people (estimating about 45%) who will only want the physical shopping experience. As such, he advised technological business innovators to be careful and not to assume that the old habits and preferences of customers will just go away or change to fit the new tech, rather they should do what they can to accommodate customer preferences within the context of the new technologies.

He has developed new software that allows his clients to customize his jewellery designs within set parameters before the design is finalized and created. He calls it “Perceptivism” and it allows his clients to, in effect, co-create jewellery with him. It basically works by presenting the customer with a webpage 3D photo of the selected jewellery piece, then allows them to stretch, push, pull or change the material by using a series of sliders on screen until the customer settles on the final rendition of the item that suits their unique tastes. Once finalized, the design is then rendered for the customer. His website can be found here.

3D fabrication is a main area of his new business, but he lamented that the biggest obstacle in the adoption of 3D printing for retail businesses is that, for the most part, the machines available are not able to produce finished goods of retail quality. He acknowledged that the industry is working hard to find/develop such machines and processes, but in the interim it will continue to be a challenge for retailers. He offers this advice to people with new ideas; “don’t let the inevitable disappointment of the reality of your project not living up to your original idea cause you to give up, keep developing and don’t flake off.”

After Isaac finished, Howard Shin, CEO of Daelim Chemicals took to the stage and spoke about materials that are, and will soon be, available for 3D printers. This area is often overshadowed by the latest developments in printer hardware, but it shouldn’t be. Mr. Shin spoke of the work being done in “smart materials” such as plastics and metals that react to pressure, heat, light, or other factors to perform some function. He used the example of robotics to demonstrate his point. Noting that if a robotic hand could be designed and printed out in a single piece, but of differing materials, it would be possible to place hundreds, maybe even thousands, of tiny pressure sensors in the hand instead of only a dozen or so that we can place in manually today. He promised that his company is actively developing such materials and promised some amazing things in the near future.

It was then lunchtime, and we joined a lively group for some traditional Korean food at a local restaurant. Everyone always thinks that Korean food is spicy…and SOME of it is, but not all of it. There were quite a number of different dishes for everyone, from cold noodle salads, to braised beef, to the standard favorites of rice and kimchee. One note; for those accustomed to long grain rice, you really need to try the short grain Asian rice. I was so amazed at the taste difference. I’ve never been much of a rice eater, as it always tasted somewhat bland to me, but the Asian rice is actually slightly sweet…and naturally sticky so you can eat it with chopsticks. Anyway, after lunch it was back to the conference to hear about the new makers in Korea.

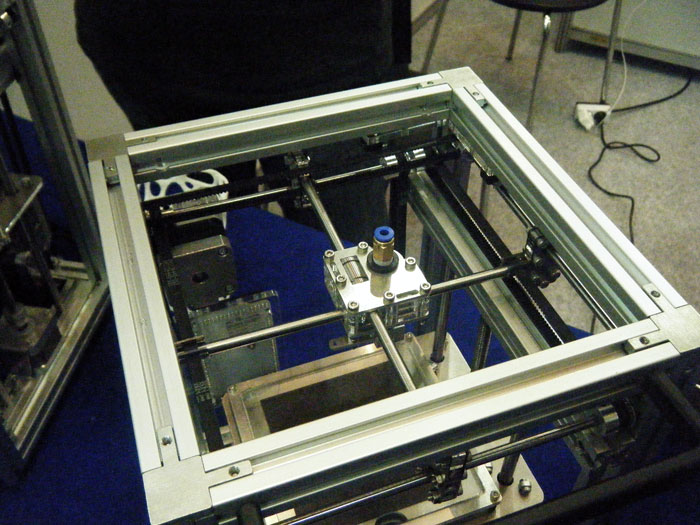

OpenCreators CEO and co-founder Kang Min Hyuck spoke about the burgeoning maker movement in Korea, calling it an evolutionary example of “collective intelligence.” He said he found this to be one of the most important things to have hit Korea in a very long time. He noted that when he was younger, he wanted to be an inventor, but the school and its teachers discouraged him from pursuing such a dream by convincing him that he would have to spend most of his time filling out paperwork, reports, and other types of forms. It wasn’t until he met his friend Choi Jong Eon, now the CTO of OpenCreators, that all that changed. Once the two of them got together they inspired each other to create new things and eventually they built their first 3D printer, a RepRap Mendel. They now have their own company and manufacture the “Almond” 3D printer and are very active building the maker community in Korea, opening maker spaces and hosting competitions for local young people. He closed by noting that, “A 3D printer is one of the strongest tools a maker can have” for releasing a person’s creativity.

Due to time constraints we had to forgo the talks by Francis Raybuck of Raybuck Associates, who spoke about the future of 3D printing and robotics, and Choi Sung Kwon of Seoil University who spoke on industrial design education and business start-ups using 3D printing. Outside the presentation hall the exhibit floor was still buzzing with activity. According to a Mediabistro spokesman we spoke to, the registered attendance had topped 7,000 people and was the largest and most well-attended Inside 3D Printing show to date.

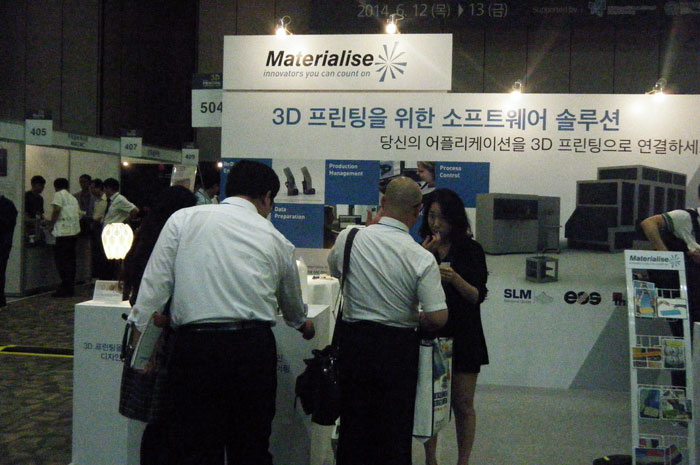

Exhibitors in attendance included; Stratasys, Rokit, Materialise, the 3D Convergence Technology Center, Mirae International Trading Co., 3D Industrial Imaging, 3D Printing Industry, AJ Networks, Anatz Inc., Artec 3D, Fablab Seoul, Canon Korea Business Solutions, Carima, Cybermed, Daelim Chemical, DYSS, ESUN, the Gyeonggi Convention Bureau, Illuminaid, KITECH, K-Tech, Organic Thinking Systems (OTS), Saehan Electronics, Seoryong Co. Ltd., SUNDO Systems, VisionTech, WONIK CUBE, Yamazen Korea, Youngil Education Systems, 3DConnection, 3D Items, Alien 3D, AM Solutions, Intelli Korea, Make: Korea, 3D Printing Studio MOA, NATURALISE, and OpenCreators.

Day 2

The second day of the conference opened with an address by You Seok Hwan, CEO and Founder of Rokit, the premier South Korean 3D printer manufacturer. He briefly described Rokit’s start and rapid growth, going from three employees to 85 in less than two years. He noted that Rokit currently exports their machines to over 10 countries, and is taking orders from over 30. He said that he wants Rokit to become the world’s number one desktop 3D printer company by 2017. Though he didn’t elaborate too much on exactly how he planned to do this, we at 3D Printing Industry will be certain to keep our readers abreast of all the latest developments of this dynamic company as they strive to reach this audacious goal.

When it came time for audience questions, one young man stood up and asked the, “what about 3D printed guns?” question. I did a face-palm and took a deep breath; but Mr. You calmly answered the young man’s question by drawing attention to the facts of the Boston bombing incident. He noted that those bombs were made of ordinary household items, most notably, pressure cookers; and while pressure cookers could be, and have been used for evil purposes, the positive utility of those devices is not in question and far outweighs their malevolent uses. 3D printers likewise are not designed for evil purposes and their positive uses far, far outweigh any negative uses. While we need to stay alert for those who wish to use them for wicked purposes, we should not let our fears of those bad uses paralyze the development of this overwhelmingly positive and beneficial technology. The young man sat down, and I started to breathe again.

At that we headed over to the Maker Summit to see the talk by San Ko, CEO of the TIDE Institute, ATEAM Ventures, and a former Korean astronaut. In has academic life he graduated from Seoul National University, and has studied at Harvard University and at the Singularity University. Truth be told, he is a bit of a rock-star in the scientific and make community here in Korea and as it turns out, one heck of a nice guy. He spoke about the coming 3rd industrial revolution and its entrepreneurs. In particular he was concerned with educating people so that they would be ready for the revolution when it finally does arrive. As he noted, the knowledge base surrounding 3D printing is still fairly limited, and not evenly dispersed, so most people will be caught by surprise when it begins to affect their individual lives.

To help remedy that he started the TIDE Institute (Technology Imagination Design Entrepreneurship) after returning to Korea from the United States. “I have always pictured myself contributing to the growth of the South Korean science and technology scene for a long time. At Singularity University, I witnessed how advanced technologies and top-tier talent shape the startup environment in the United States. I believed that Korean kids might develop a passion for starting something new, rather than just going to work for established conglomerates such as Samsung, LG, or Hyundai.” He went on to explain how TIDE opened the first FabLab Seoul and started the Make-a-thon project which challenges young Koreans to create and build whatever they can imagine by giving them access to the tools needed to do amazing things, such as 3D printers, laser cutters and CNC machines.

When he had finished his presentation, which seemed to really strike a powerful chord with the predominately young Korean audience, he was mobbed by a large group of people. Some wanted to ask a question or two about space or his businesses, but most just wanted the chance to pose and get a photo taken with this extremely popular “hometown” hero…and true to his outgoing and gentle character, he indulged them all.

Other Maker Summit speakers that day included Turlif Vilbrandt, Founder and CTO of Uformia, who spoke on what he called the “N dimension” or designing 3D objects in a more natural way. Later, Hong Chan Woo, CEO of Illuminaid Co., Ltd., followed by talking about the needs of the hobbyist and 3D printer selection. Much to our disappointment, we had to miss both of their talks due to other engagements. There was so much to do and see, and so little time to get it all in.

Out on the exhibition floor we spoke to Daniel Thompson and Jihyun Lee at the Stratasys booth. They expressed their appreciation and pleasure at seeing a 3D printing specific event being held in Korea. We had spoken to them at the Seoul SIMTOS industrial machine show early this year, where 3D printing companies got lumped in with all sorts of industrial devices, and they had noted that the industry was now big enough that it should have its own forum…and now it did. Mr. Thompson said that, “this show is a good demonstration of how 3D printing is growing in Korea.”

Ms. Lee pointed out that the Seoul show was one of the biggest such events she has seen. She said that at the Singapore show the main players, Stratasys and 3D Systems, were all there and the feel was more “academic,” but that here (in Seoul) there were a lot more local companies and vendors and had much more of a business feel to it. She also expressed enthusiasm for the markets in Korea, pointing out that Korea is strong in both design and manufacturing capabilities…something not necessarily true for other areas.

Mr. Thompson was pleased with the wide mix of people attending the show, noting that some were there doing basic research, but that many others were there to confirm their decisions to purchase. He noted that while the Korean government’s policies are still in their infancy, he expected that to change very soon. Referring to some of the statements made by certain governmental officials, he anticipates that Korea may follow other countries by instituting programs to encourage the technological adoption/development. “In Australia for example,” he said, “some state and local governments will match dollar for dollar industrial investment to help bring 3D printing to their areas and some governments are putting a lot of money into their universities to identify future engineers with new skills and providing students with access to the tech. They are then inviting businesses to come, see, and test the machines before they (the businesses) invest themselves.” He believed this was important, as industrial machines are still very different than desktop models. “Getting a nylon part to correlate to a manufactured component within + or – of the exact parameter needed is still the difference between a personal system and a production system. It all depends on what the user’s needs are.”

We then spoke to one of the local vendors that Ms. Lee had referred to earlier. Hwang Inyong of Organic Thinking Systems (OTS) is a local Korean Deltabot manufacturer. When we met him, he said he was excited, but very tired. He said that preparing for the show, and then working the long hours of the show, was exhausting. His booth had been filled with curious attendees since he first set up, and had not slowed down once. “I see more people interested in 3D printing than I thought. They showed high interests in my booth and it is a good motivation as a 3D printer developer. Interaction with them also helps me figure out where both the industry and my company should be headed.”

John Hornick, a partner with the Washington DC law firm of Finnigan, Henderson, Farabow, Garrett & Dunner, LLP closed the show for us with a talk on “3D printing and the future (or demise) of intellectual property.” His fascinating talk tackled a number of related topics, but one in particular was the transformative power of a new technology. Second only to the “3D gun” question in popularity, is the question about the “loss of jobs” to additive manufacturing processes. John tackled this by comparing the coming transition to that of the transition from the horse to the automobile. Sure jobs were lost, but even more jobs were created. The new jobs that evolved could not have been imagined by people only familiar with the horse, and those new jobs generally required more training and knowledge and were less menial, and generally paid more…so while some disruption is to be expected, we should not be overly afraid of the change.

He also noted that as the current IP laws stand, unless they are changed, they will likely become irrelevant. He said that trade secrets may eventually rise up to become the dominate form of IP. In the interim, while there has been nearly no litigation between members of the 3D community yet, he does expect a lot of patent conflicts to arise in the near future as more and more money moves into the field. It will probably taper off soon after, but no one can say for sure.

There were many other fine guest speakers on Friday which due to time constraints we were not able to cover, and we would like to extend our apologies to them. These included; Shim Jin Soo of the Korean Ministry of Trade, Industry and Energy, Wim Michiels, the CEO of Materialise Malaysia, Lee Byung Keuk, CEO of Carima, Mike Vasquez, Yang Yihu, CEO of ESUN. We will be sure NOT to miss you next time.

We squeezed in as much as we could and it was an AMAZING two days. The organization of the show was top-notch and Inside 3D Printing is all set to return to Korea next year.

The next stop on the calendar for this global 3D printing event, however, is Inside 3D Printing Melbourne, Australia, which will take place 9-10th July.