Due to its high heat resistance, PEEK (Polyether Ether Ketone) is often used for the production of demanding industrial parts, such as valves and pistons, as well as for medical implants. With a melting point of 662 degrees Fahrenheit, PEEK has previously only been available for 3D printing with industrial SLS (Selective Laser Sintering) 3D printers. Recently, however, Karlsruhe, Germany-based company INDMATEC announced that they have developed an FFF/FDM 3D printer that can print high-temperature polymers including PEEK.

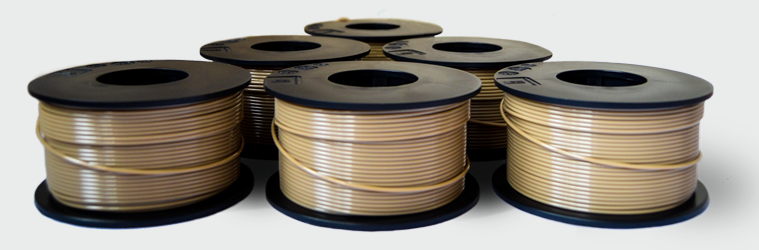

Featuring a build volume of 155 x 155 x 155mm, the PEEK 3D printer is equipped with a hotend that can reach temperatures up to 788°F and an enclosed build chamber with parts built on non-reactive metals. It’s prime material will be PEEK, specifically Indmatec’s flagship PEEK filament, though it is capable of printing with other high-temperature polymers. PEEK has several beneficial properties ranging from bio-inertness, mechanical stiffness, biocompatibility, high-temperature resistance and chemical resistance. The standard 3D printing materials, ABS and PLA typically melt quickly when heated, but PEEK holds up, making it ideal for more traditional subtractive manufacturing.

Professor Okolo explains, “The development preceded years of research. To make PEEK usable as filament and concurrently develop an FDM 3D printer, that meets the challenging demands of the material.” Tony Tran-Mai, CEO and Founder of INDMATEC says, “It was our goal to make additive manufacturing economically accessible for small- and medium-sized enterprises.”

The PEEK 3D Printer has a price point of about $10, 734 or 9590 euros, and also features software designed to make PEEK 3D printing a “one-click procedure”. We will continue to follow the progress of this new 3D printer and watch how well it does in creating a high-temperature 3D printing market.