Californian launch service provider Rocket Lab has successfully fired a pioneering new NASA satellite towards a ‘lunar orbit.’

Launched via the firm’s 3D printed engine-powered Electron rocket, the microwave-sized ‘CAPSTONE’ CubeSat is designed to pave the way for humanity’s return to the Moon, as part of NASA’s Artemis mission. Specifically, the device is set to become the first spacecraft to enter a Near Rectilinear Halo Orbit (NRHO), the planned trajectory of the Gateway outpost being built to support lunar excursions.

“Today’s launch was an important step in humanity’s return to the Moon and a testament to the determination, resolve, and innovation of the hundreds of people behind CAPSTONE,” said Rocket Lab Founder and CEO, Peter Beck. “Rocket Lab was founded to open access to space and enable ground-breaking missions like this that push the limits of what’s possible with small satellites.”

“While CAPSTONE’s journey to the Moon has only just begun, we’re proud to have safely delivered CAPSTONE to space.”

Rocket Lab’s Rutherford engine

Having facilitated the launch of 147 satellites over the last sixteen years, Rocket Lab has established itself as a reliable partner for aerospace firms and space agencies alike. In large part, the company’s offering revolves around its Neutron and Electron launch vehicles, which are powered by its Electron Beam Melting (EBM) 3D printed Rutherford engine.

Now having been 3D printed more than 100 times, the Rutherford is a liquid propellant fuelled carbon composite engine, capable of carrying a payload of up to 225 kilos and reaching a thrust of 120N, making it ideal for firing SmallSats into orbit.

Since the Electron’s first successful mission, Rocket Lab has been commissioned to launch several R&D satellites. In 2020, the company fired a weather satellite into space as part of the Air Force Research Laboratory’s Monolith program. Earlier this year, the firm was also selected to launch NASA’s ‘VADR’ payloads, in a $300 million project set up to help identify new opportunities for US aerospace businesses.

Paving the way for a lunar return

NASA’s Cislunar Autonomous Positioning System Technology Operations and Navigation Experiment or ‘CAPSTONE’ satellite has been built to facilitate its Artemis mission. For those unfamiliar, the program’s primary goal is to return humans to the Moon for the first time since 1972, and set up a base on the celestial body’s surface.

In a bid to ramp up its preparations for the mission, NASA has regularly turned to additive manufacturing. During 2020, the agency developed 3D printed nozzles and combustion chambers that could be deployed in the program, shortly after working with a team at Tuskegee University to test 3D printed parts of the Artemis lander.

With its CAPSTONE launch on June 28, 2022, NASA’s latest adoption of 3D printing-enabled technologies has now seen it begin preparations for the deployment of Gateway, a space station designed to enable future lunar and martian exploration.

Built by Tyvak Nano-Satellite Systems, the CubeSat will do so by trialing NRHO, an orbit that’ll see it pass as close as 3,000 km and as far as 70,000 km from the lunar surface, in a way that enables it to get caught between the Earth and Moon’s gravitational forces, and rotate in tandem with the latter, keeping it in position.

Having announced the CAPSTONE’s “flawless” launch via Rocket Lab’s Electron launch vehicle, NASA says it’s now in a stable orbit, ready to be propelled towards the Moon. From its initial orbit, the spacecraft bus onto which the CubeSat is affixed, is set to perform a series of orbit-raising maneuvers over five days, that’ll see it stretch its orbit into a prominent ellipse around Earth.

Once this phase is complete, the device will be fired towards the Moon at 24,500 mph, setting it on a ballistic lunar transfer that’s expected to take four months. With the help of the Sun’s gravity, it’s anticipated that the CAPSTONE satellite will go as far as 963,000 miles from Earth, before being pulled towards the Earth-Moon system, in a sinuous track which follows deep space gravitational contours.

Those interested in following the CubeSat’s journey can do so via NASA’s Eyes on the Solar System real-time 3D data visualization tool, starting around one week after its launch.

Driving satellite R&D with 3D printing

Of course, 3D printing isn’t just applied in the manufacture of the rockets used to fire satellites into orbit, it also continues to be deployed as a means of producing the devices themselves. Fleet Space launched its partially-3D printed Centauri 5 satellite onboard a SpaceX Falcon 9 rocket earlier this month, complete with fully-printed metal patch antennas.

Recently, 3D Systems also announced that Airbus has contracted it to 3D print “critical components” of the OneSat satellite. The device, which is designed to be fully-reconfigurable in-orbit, enabling it to change coverage area, capacity and frequency on the fly, is being built in-part using the firm’s DMP Factory 500.

Elsewhere, companies like Mitsubishi Electric have even come up with a way of freeform 3D printing satellite antennas in-orbit. Using the firm’s technology, which revolves around a newly-developed liquid resin that’s capable photopolymerizing via the sun’s ultraviolet (UV) rays, it could be possible to manufacture parts larger than the satellite itself.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

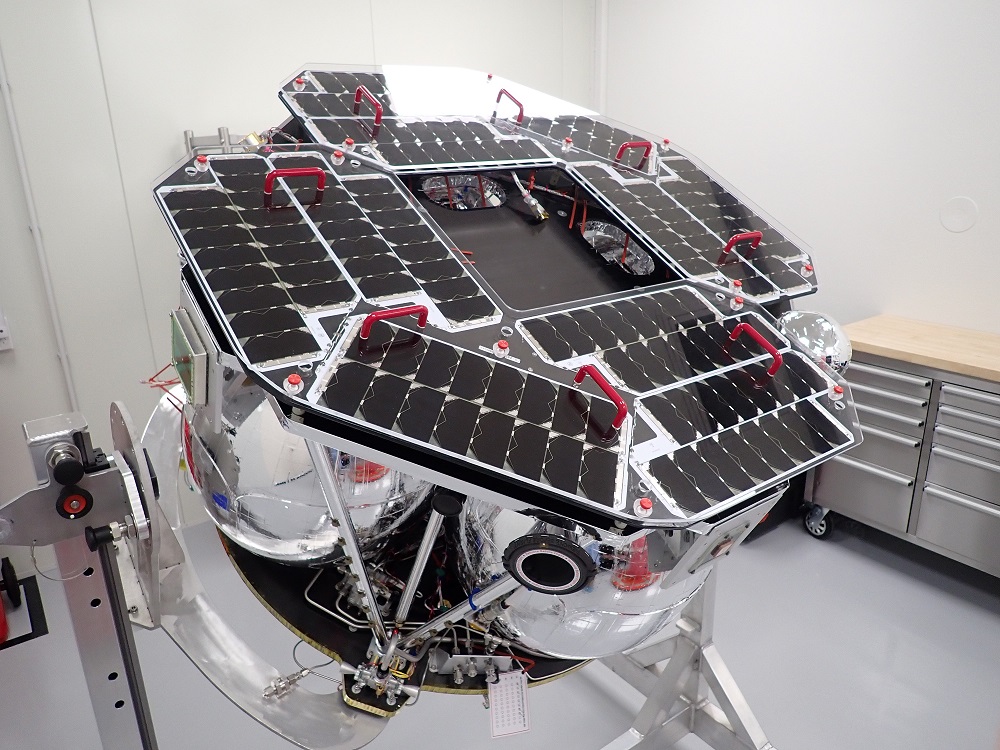

Featured image shows the Electron rocket taking off with the CAPSTONE satellite. Photo via Rocket Lab.