Rocket Lab, a US aerospace company, has successfully reached orbit for the first time. Powering the mission is a 3D printed engine, as we reported after the first successful launch in May 2017, the Electron’s Rutherford engine “is the first of its kind to use 3D printing for all primary components.”

On the afternoon of Sunday 21st January at a spaceport on the southern tip of Mahia Peninsula the privately owned company successfully launched two Spire Lemur-2 CubeSats.

“3D printing is a crucial factor”

Less than nine minutes after launch, the Electron launch vehicle reached orbit. I asked Peter Beck, CEO and founder of Rocket Lab about how 3D printing has played an important role in reaching this milestone.

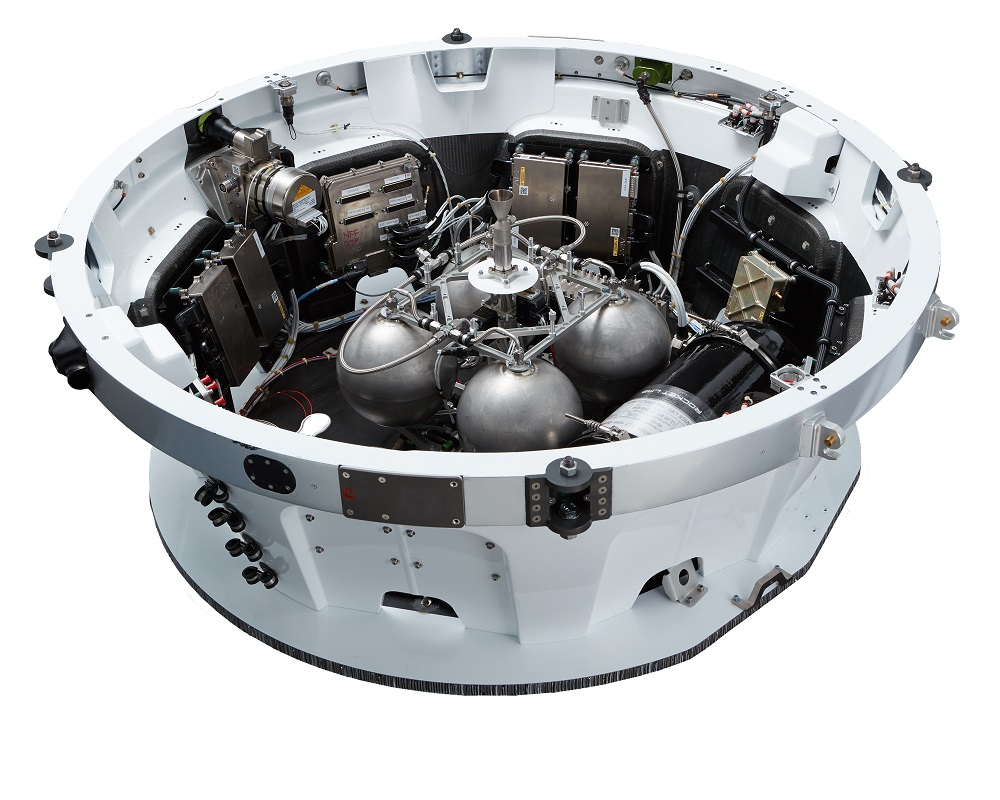

“The Curie engine, much like the Rutherford engine, is 3D printed using an additive manufacturing process,” explains Peter Beck, CEO and founder of Rocket Lab.

“3D printing is a crucial factor in Rocket Lab being able to achieve unprecedented launch frequency. While it can take months to build a rocket engine using traditional methods, we can print a new engine every 24 hours, allowing us to produce and launch vehicles faster than the industry has ever seen.”

The successful mission also featured a previously unrevealed aspect, a kick stage. This is the aforementioned restartable liquid propulsion and 3D printed engine called Curie. Peter Beck explains that this kick stage increases orbital options, specifically for “rideshare customers that have traditionally been limited to the primary payload’s designated orbit.”

“Until now many small satellite operators have had to compromise on optimal orbits in order to reach space at an accessible cost. The kick stage releases small satellites from the constricting parameters of primary payload orbits and enables them to full reach their potential, including faster deployment of small satellite constellations and better positioning for Earth imaging.”

Scaling up for more launches

The Curie kick stage works with the Electron launch vehicle and has a payload capacity of up to 150 kg. It can also be used to de-orbit the stage after mission completion, and means that Rocket Lab aims to reduce the debris left in orbit.

Peter Beck also gave an insight into the future of the company, “Right now the focus for Rocket Lab is on scaling up production to meet customer demand and get more crucial infrastructure on orbit at a greater frequency.”

As production is scaled up, the frequency of launches will also increase. “There are currently five Electron vehicles in production and we’re working to a launch cadence of one per month by the end of the year,” said CEO Beck.

Let us know if you think Rocket Lab’s use of 3D printing is the leading Aerospace application of the technology. Make your nominations for the 2018 3D Printing Industry Awards now.

To stay up to date with all the latest 3D printing news and subscribe to our free newsletter, follow us on Twitter, like us on Facebook.