When it comes to 3D printing, the U.S. Air Force is taking things seriously. The Air Force Research Laboratory (AFRL) is a leading driver for developing the technology, and has recently employed the Synchrotron to investigate filler for 3D printed polymers.

For years, bases around the country have also been trialling 3D printers for spare part production, and even the Pentagon has taken note of the technology’s potential.

Now, in a $2.9 million with Renaissance Services, Inc. the U.S. Air Force is making a firm commitment to integrating 3D printing in its legacy aircraft maintenance program.

RECHARGE old parts

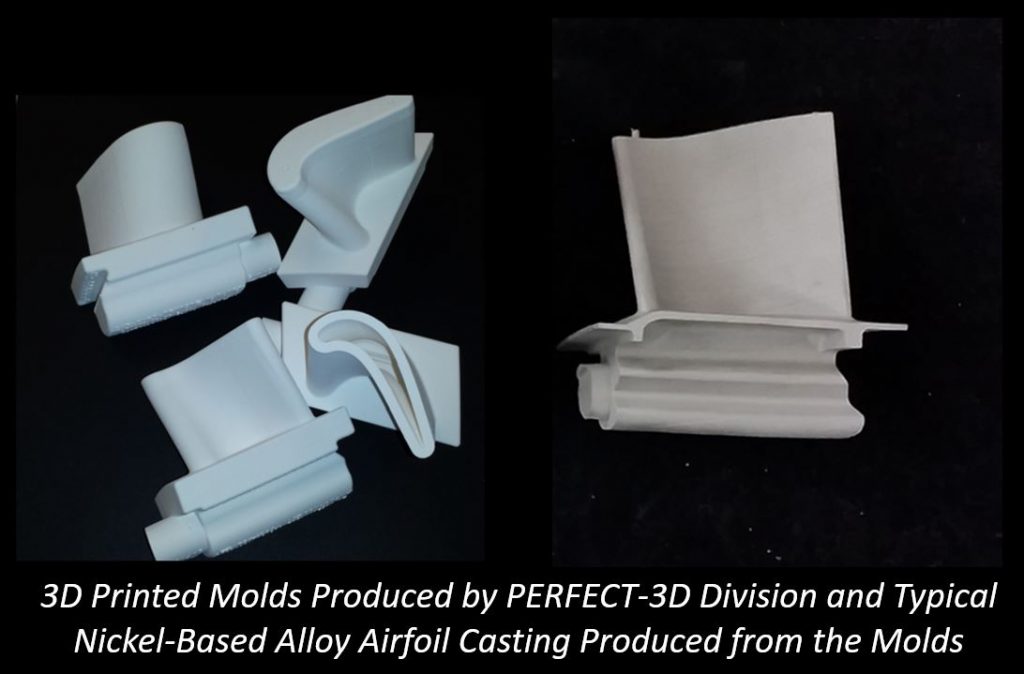

Renaissance Services has been selected by the U.S. Air Force for its expertise in 3D printing ceramic tooling for aerospace-grade parts. The project is titled RECHARGE, which is short for Rapid Engineered Castings: Housing for Aircraft & Reliable Gearboxes for Engines.

In RECHARGE, Renaissance will combine its ceramic 3D printing intelligence with traditional castings to make production of now unsupported critical parts faster and cheaper for a base.

“The Air Force has a long list of critical parts for aircraft and engines that have not been produced for years,” explains Renaissance co-founder and RECHARGE Program Manager Robert Morris.

“It’s not uncommon for production sources to be unknown, tooling to be nonexistent, and essential technical data to be very limited.”

In addition, “Many of these parts start as castings. These parts can cost upwards of $50,000 each and have lead times of more than a year.”

Rapid response to part demand

So far, a 3D printed mold to casting trial of an airplane gearbox managed to improve component lead time by upwards of 90%.

It took only 30 days to make the part. If done with traditional methods, it would have typically taken longer than a year. The rapid-turnaround time is facilitated by Renaissance’s intelligent software system that can 3D print models directly from a component CAD file.

As revealed by a recent case study, Renaissance may be using Prodways 3D printers to make Air Force legacy parts. The company has been using the ProMaker L5000 DLP system for the purpose. Renaissance has developed their own proprietary PERFECT-3D ceramic composition. There is also the Prodways ProMaker V6000 Ceramic DLP system.

A legacy with critical needs

The U.S. Air Force started moving legacy aircraft maintenance to contractors in 2016, freeing-up experienced engineers for next generation F-35 Lightning II development.

Legacy systems in the fleet include the supersonic F-16 Fighting Falcon, the “Warthog” A-10 Thunderbolt II jet, and the C-130 Hercules – a troop and cargo transporter that has also received 3D printed parts from the Australian Department of Defence.

Morris concludes, “It’s going to be an interesting couple of years as we prove that legacy systems don’t have to stand at the back of the line to have their critical needs met.”

Read more about the latest additive manufacturing applications in aerospace, automotive and more with a subscription to the 3D Printing Industry newsletter. You can also follow us on Twitter, and like us on Facebook.

Nominate the best additive manufacturing applications in the 2018 3D Printing Industry Awards.

Featured image shows a U.S. Air Force legacy “Warthog” A-10 Thunderbolt II jet. Photo via Boeing