Scientists at Ludwig Maximilians University in Munich have developed a new technique to make organs, and even whole organisms transparent – which aims to lead to high-fiedlity 3D printed models.

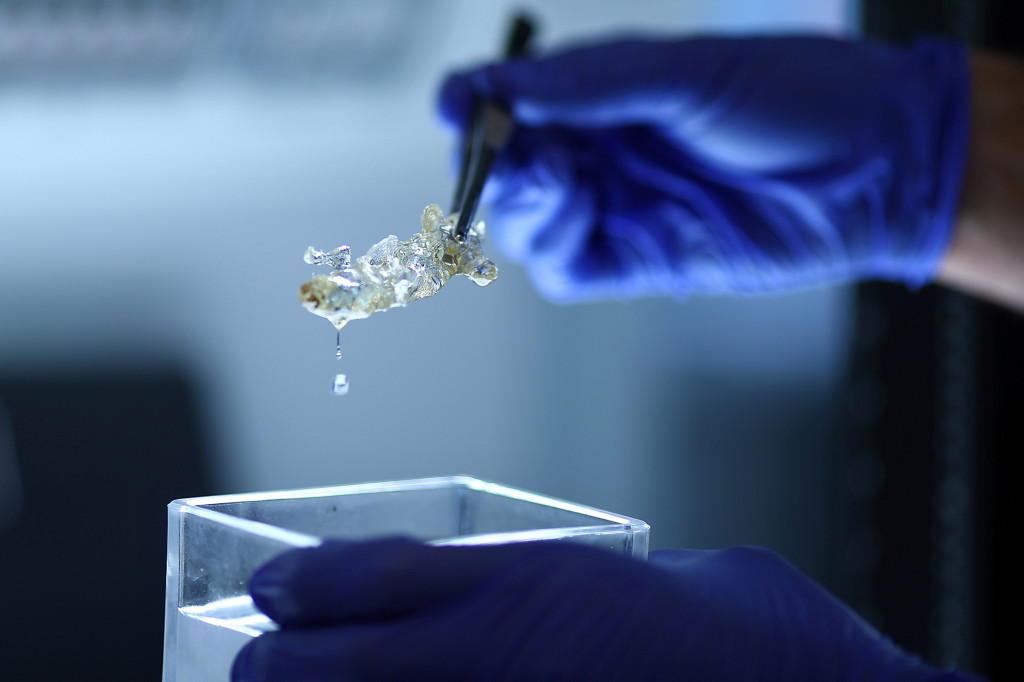

The research team led by Dr. Ali Ertuerk developed the new technique, referred to as vDISCO, which uses a solvent to make living organs such as the brain and kidneys transparent. The items are then scanned using bioimaging technology (lasers incorporated into a microscope), enabling researchers to capture a high resolution 3D image of the entire structure, including the blood vessels and the exact location of cells.

So far, the vDISCO procedure has enabled Dr. Ertürk and his team to obtain detailed scans of a human brain, pancreas and even an entire mouse. The real goal is to create a functioning 3D printed human organ using these blueprints.

Towards a 3D bioprinted pancreas

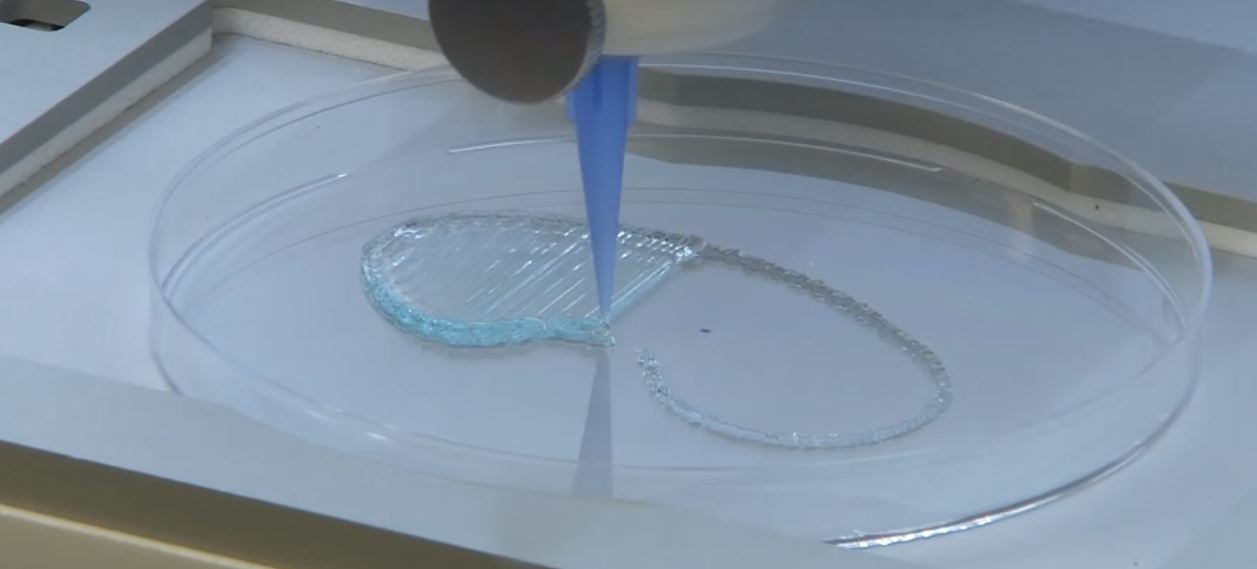

3D printing organised tissue aggregates like hearts and kidneys is a complicated process, that requires the interpolation of multiple materials. Ertuerk’s team at Ludwig Maximilians University is currently using a CELLINK BIO X 3D bioprinter to produce its organ prototypes.

With this machine they have already begun work on creating a 3D bioprinted pancreas using the detailed scans from the vDISCO process. The procedure involves 3D printing a scaffold of the organ out of a soluble polymer – which will then be injected with stem cells. After the stem cells multiply to fill out the scaffold, the polymer will removed leaving behind a highly realistic organ. However achieving full functions of such models is still a tremendous challenge.

Erturk’s team plan to create a working bio-printed pancreas over the next 2-3 years and to develop a kidney within 5-6 years. Animal clinical trials of such models are currently planned for the long term, and not expected for another 10 years.

More detailed development

Explaining the reasons for adding vDISCO as prepartion step in the 3D bioprinting process, Dr. Ertürk said, “Until now 3D printed organs lacked detailed cellular structures because they were based on images from computer tomography or MRI machines.”

In this method, he adds, “We can see where every single cell is located in transparent human organs. And then we can actually replicate exactly the same, using 3D bioprinting technology to make a real functional organ. Therefore, I believe we are much closer to a real human organ for the first time now.”

While it still may be a long road to creating fully functional and transplantable organs using 3D bioprinting, there has been a large number of advancements in the technology in recent years.

In 2017 3D bio-printing company Organovo, headquartered in San Diego, successfully 3D printed the microscopic veins that make up a kidney, and just the year before that they successfully planted 3D bioprinted liver tissue into lab-bred mice. The award winning Lewis Lab at Harvard University has taken vital steps forward in the organ on a chip research and several methods for creating multimaterial structures have emerged, including the Kenzan process.

Subscribe to the 3D Printing Industry newsletter for the latest advances in 3D bioprinting. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Voting is open for the 2019 3D Printing Industry Awards.

Featured image shows Dr. Ali Ertuerk inspecting a transparent mouse create using the vDISCO process. Image via Reuters.