A research article published in The Optical Society (OSA) journal Optics Letters describes how researchers have produced a 3D printed high-resolution digital holographic microscopy (DHM) microscope.

The researchers focused on creating a small but powerful and cost-effective microscope that would be robust enough to be used by professional biological researchers in the field without access to an optical table. The instrument is able to provide 3D images with twice the resolution of traditional DHM systems, which are typically used on optical tables in laboratories.

Providing medical diagnostics for areas with limited health care

As described in the study, the 3D printed microscope could potentially be utilized to diagnose diseases like malaria, sickle cell disease, diabetes and others. The simplicity and low cost of constructing the instrument, which is made entirely from 3D printed parts and commonly found optical components, could “increase access to low-cost medical diagnostic testing,” according to research team leader Bahram Javidi from the University of Connecticut, which he claims “would be especially beneficial in developing parts of the world where there is limited access to health care and few high-tech diagnostic facilities.”

Javidi continues, commenting that:

“The entire system consists of 3D printed parts and commonly found optical components, making it inexpensive and easy to replicate.”

“Alternative laser sources and image sensors would further reduce the cost, and we estimate a single unit could be reproduced for several hundred dollars. Mass production of the unit would also substantially reduce the cost.”

Using a powerful 3D printed DHM system on the go

The 3D printed microscope is based on DHM technology, a process that produces a hologram of a sample using interference created between light waves, which is then converted into a 3D image. This microscopy approach is useful in biomedical research as it allows scientists to non-invasively visualize and quantify biological tissue. However, it usually requires a complex optical setup in a stable environment to produce accurate measurements, hence why it is generally limited to laboratories.

With the 3D printed microscope, the researchers were able to use 3D printing to create a DHM microscope that is “is robust and compact to allow for a field-portable implementation”, while also offering high temporal stability, overcoming the mobile limitations of traditional DHM.

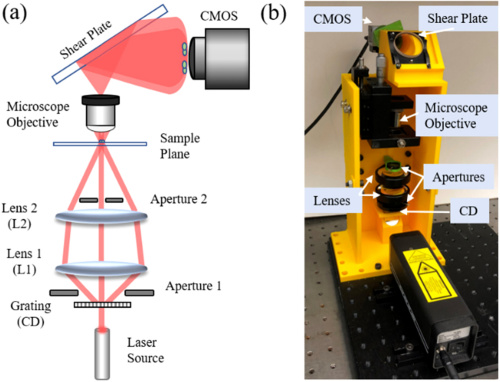

Furthermore, the research team managed to improve upon the resolution of DHM by combining it with structured illumination (SI), a “super-resolution” microscopy technique used to extend the resolution of an imaging system. This was achieved using a structured light pattern acquired from a clear compact disc (CD). Javidi states “3D printing the microscope allowed us to precisely and permanently align the optical components necessary to provide the resolution improvement while also making the system very compact.”

A higher resolution than laboratory microscopes

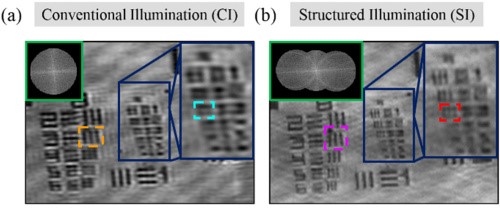

Putting their 3D printed microscope to the test, the research team recorded images of a resolution chart, using the 3D printed DHM system with both SI microscopy and conventional illumination.

Evaluating the performance of the instrument against traditional DHM, the 3D printed microscope could achieve a resolution of 0.775 μm, which is double that of the native DHM system. The researchers also conducted additional experiments which demonstrated the 3D printed DHM system’s stability, as it was able to analyze fluctuations in biological cells over time, a process that requires measurements on the scale of a few tens of nanometers. To then prove its applicability for biological imaging, researchers used the 3D printed microscope to provide a high-resolution 3D image of green algae, shown below.

According to the researchers, the 3D printed DHM system is ready for practical use, with plans for it to be used in biomedical applications like cell identification and disease diagnosis. They will also work with international partners to research disease identification in remote areas with limited health care access, and continue to improve the resolution of the system without increasing the cost of manufacturing it.

3D printed microscopes for everyone

The research team behind the 3D printed DHM microscope consists of Timothy O’Connor, Bahram Javidi, and Ana Doblas of The University of Memphis. With their research paper in the OSA’s Optics Letters, they join various other researchers and companies using 3D printing to make microscopes more accessible in the education and research sectors. For example, scientists at RMIT University have developed a 3D printable “clip-on” filter that can turn smartphone cameras into a powerful microscope. The filter provides a practical option for a point of care diagnostic tool or research device, for remote healthcare clinics and field research groups.

Elsewhere, researchers at the UK’s University of Bath designed an open source 3D printed microscope prototype, which is intended to increase the accessibility of educational and functional scientific tools. Dr. Richard Bowman, who worked on the project said, “With consumer electronics being so cheap nowadays we can actually get a surprisingly long way and make a high-quality instrument for serious microscopy.”

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D rotation of a green algae sample imaged with the 3D printed microscope. Video via Bahram Javidi/OSA