Nexxt Spine, an Indiana-based medical device manufacturer, has expanded its metal 3D printing capabilities with the installation of two Concept Laser Mlab 100R systems from GE Additive.

The pair of machines are the fourth and fifth additive manufacturing acquisition from the company since 2017 and will support the design and production of Nexxt Spine’s spinal fusion implants.

“Additive is booming,” stated Alaedeen Abu-Mulaweh, director of engineering at Nexxt Spine.

“We used the first Mlab primarily for R&D purposes, but soon realized that further investment in additive technology could add value not only to our overall growth strategy but also at a clinical application level with the ability to develop implants with very intricate micro-geometries that could maximize healing.”

3D printed spinal implants

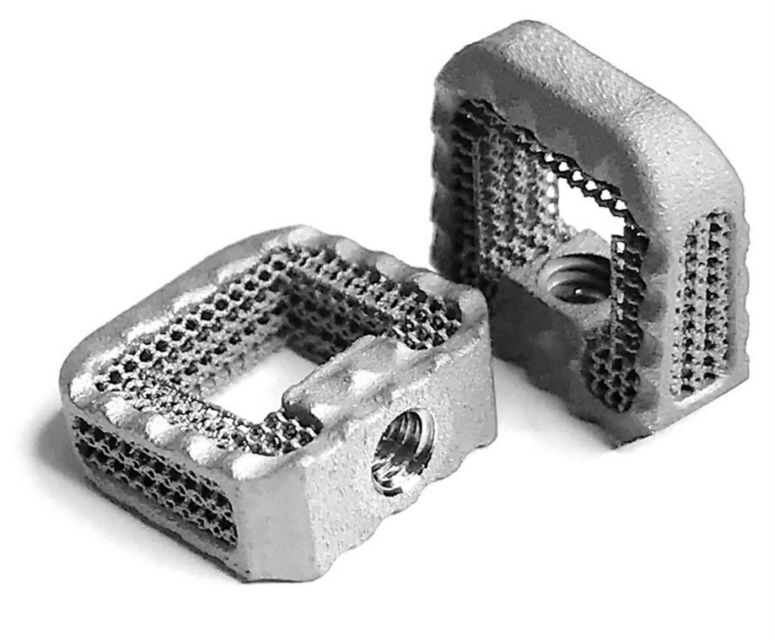

Founded in 2009, Nexxt Spine manufactures spinal implants and surgical instruments to innovate and improve upon spinal procedures. With its shift into industrial 3D printing two years ago the company launched the MATRIXX family of porous titanium spinal fusion implants with novel 3D printed cellular scaffolding.

Presently, the company has 16 product lines available within the U.S. and all of its devices are created at its facility in Noblesville. According to the company, the investment in Concept Laser Mlab machines allows its team to control the entire design, production, and distribution process in-house.

“Over the past two years, we have made a seamless jump from R&D to serial production and in doing so have significantly accelerated the time from concept to commercialization,” added Abu-Mulaweh.

Improving cellular healing

Abu-Mulaweh continued, “Titanium – porous or otherwise – is physically incapable of biological remodeling, so using additive to directly mimic the structural randomness of bone doesn’t make a whole lot of sense.”

“Rather than simply looking like bone, Nexxt MATRIXX was designed with functionality in mind to fulfill our vision of actively facilitating the body’s natural power of cellular healing.”

Earlier this year, Nexxt Spine began developing its 3D printed bone healing spinal implants with MTS Systems Corporation, a global manufacturer and supplier of simulations and testing systems.

“We are seeing ongoing adoption of additive manufacturing in the orthopaedic industry and an exciting shift from research and development to serial production,” said Stephan Zeidler, senior global and key accounts director for the medical sector at GE Additive.

“Early innovators like Nexxt Spine are scaling up and there is a significant increase in production volumes. [Its] another great example that shows the power of our Mlab machine.”

Vote for the best “Medical, dental or healthcare application” for the 2019 3D Printing Industry Awards.

Subscribe to our 3D printing newsletter and follow us Facebook and Twitter for the latest additive manufacturing updates.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image show Nexxt Matrixx Vertebral Body Replacement implant 3D printed in titanium. Image via Nexxt Spine.