Scientists from Harvard Medical School have developed a novel algae-based bioink that once 3D printed into soft tissue structures, demonstrates enhanced cell viability.

The team formed their bioink by combining a photosynthetic algae and human liver cells into a hydrogel matrix, then used it to 3D print hexagonal structures featuring lifelike liver ‘lobules.’ Due to the algae’s natural oxygen-emitting tendencies, the bioprinted human cells multiplied, showing increased functionality, and producing liver-specific proteins.

In future, the researchers believe that their new bioprinting technique could be applied in areas ranging from drug development and personalized medicine, to healthy algae-based snacks.

“The study is the first true example of symbiotic tissue engineering combining plant cells and human cells in a physiologically meaningful way,” said the paper’s senior author Y. Shrike Zhang. “Our study provides a unique example of how we can harness the symbiotic strategy, very often seen in nature, to promote our ability to engineer functional human tissues.”

The urgent need for 3D bioprinted tissues

Organ donor shortage remains a significant problem around the world, and according to World Health Organization figures, only around 10 percent of transplant demand is currently being met. As a result, there’s an increasing urgency to the development of artificial alternatives, and 3D bioprinting has enabled significant progress in this area in recent years.

Despite the varying approaches taken by researchers, the resulting cell-laden structures have often lacked the cell viability needed to make them useful in end-use scenarios. Scientists from Washington State University (WSU), for instance, have also created a naturally-enhanced hydrogel, but it’s not yet ready for medical use.

Cell viability is largely rooted in their level of oxygen exposure, and the homogenous distribution of O2 is proven to facilitate cell growth. However, prior attempts to oxygenate cell-laden hydrogels using oxygen-distributing biomaterials have stalled, due to damaging by-products and inconsistent release profiles.

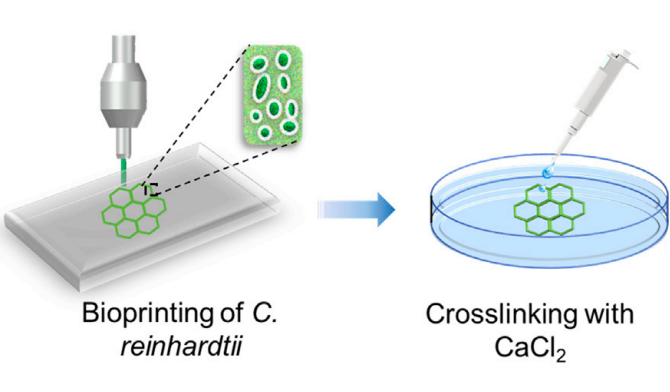

In order to overcome these limitations, the team adjusted the algae-laden hydrogels developed at the Dresden University of Technology, to include higher cellulose concentrations. The natural polymer not only provided integrity to the scientists’ hydrogel, but eventually, it proved capable of oxygenating the tissues they went on to 3D print.

The Harvard team’s algae-laden hydrogel

The team created their hydrogel by combining Carboxymethyl cellulose with gelatin, PVA and alginate, and tweaking the quantities of each one to optimize the ink’s viscosity. Once the team had identified the ideal mix, they used it to 3D print a series of honeycomb structures, with each comprising seven hexagonal lobules.

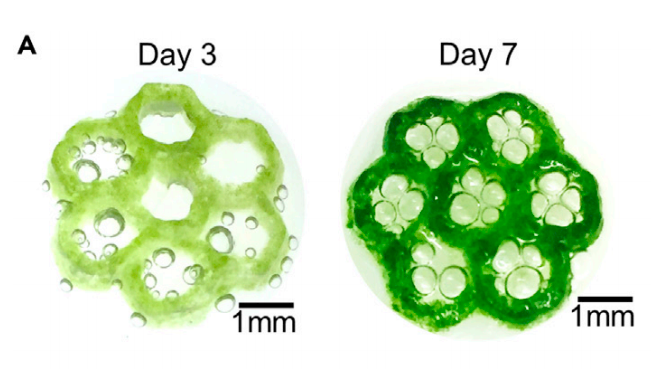

During the printing process, the researchers created a series of six, ten and twenty-layered tissues which formed a 3D tubular grid-like pattern. The scientists then mixed different levels of the C. reinhardtii photosynthetic algae and 10 percent fetal bovine serum into the additive constructs, and observed encouraging results.

The bioprinted algae released oxygen in a photosynthetic manner, which enhanced the viability and functionality of the liver cells, without affecting the bioink’s printability. Additionally, in a final step, the team added the cellulase enzyme to dissolve their bioink, and found that it left hollowed-out microchannels behind.

Filling these chambers with human vascular cells enabled the scientists to create liver-like tissues that demonstrated good cell growth and produced natural proteins. While cell structures that didn’t include algae infusions only exhibited a viability of 70 percent, those that did, showed a survivability of up to 92 percent.

“Development of such a fugitive bioink that allows initial oxygenation and subsequent vessel formation within a single tissue construct has not been reported before,” concluded Zhang. “This a critical step toward successful engineering of viable and functional tissues.”

The health benefits of adopting algae

Algae is not only healthy for the human body, but it also has a role to play in reducing greenhouse gas emissions, and its green credentials have increasingly made it the subject of 3D printing-related research.

Scientists from the Dutch University of Wageningen and Spanish University of Valencia, have deployed a sea-dwelling algae to 3D print a selection of healthy cereal snacks. The team has theorized that they could customize the shape, texture and color of algae-based foods to make them more appealing.

Elsewhere, a joint team from the University of Cambridge and UC San Diego has 3D bioprinted coral-mimicking structures that are capable of growing microscopic algae. By fine tuning the cultivation of algae, the scientists aim to develop a method of reducing greenhouse gas emissions in developing countries.

The researchers’ findings are detailed in their paper titled “Symbiotic Photosynthetic Oxygenation within 3D-Bioprinted Vascularized Tissues.” The study was co-authored by Sushila Maharjan, Jacqueline Alva, Cassandra Cámara, Andrés G. Rubio, David Hernández, Clément Delavaux, Erandy Correa, Mariana D. Romo, Diana Bonilla, Mille Luis Santiago, Wanlu Li, Feng Cheng, Guoliang Ying and Yu Shrike Zhang.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the six-layered configuration of the Harvard team’s cell-laden algae-infused structures. Photo via the Matter journal.