What defines 3D Printing? Here at 3DPI we often ask ourselves that, especially when facing new, innovative and advanced manufacturing processes that somehow involve 3D structures. Strictly, 3D printing refers to direct digital manufacturing, layer by layer, from 3D digital models; more loosely it is used to describe any manufacturing process that uses automated additive techniques.

Hydrogel Bioprinting is 3D printing because it is additive though it is actually a 2D process (though at a cellular/organic level these terms get fuzzy). Lego is an additive process, though is it 3D printing? What about contour crafting? Perhaps we can refer to 3D printing as any robotic manufacturing process that is also additive.

I have often argued that future space stations – the gigantic ones we see in sci-fi movies – will have to be built by additive processes employing robots, but it would be difficult to envision a single 3D printing robot large enough to make an Imperial Star Destroyer or a Death Star.

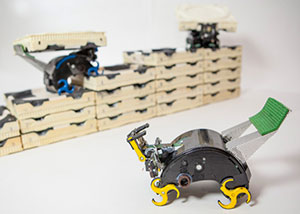

Led by principal investigator Radhika Nagpal, Fred Kavli Professor of Computer Science at Harvard SEAS (she is also a core faculty member at the Wyss Institute, where she co-leads the Bioinspired Robotics platform) the team designed the robots to observe each others’ changes to the environment and act accordingly. Each robot executes its building process in parallel with others, but without knowing who else is working at the same time. If one robot breaks, has to leave or faces unexpected changes, it does not affect the others.

The TERMES project was inspired by a the concept of stigmergy, the kind of implicit communication adopted, for example, by termites. It may not be a pure 3D printing process but it does feature many of the same characteristics: digital instructions, no waste of materials, robotic execution, additive construction (sure, bricklaying is additive too).

The process is scalable and can be executed by five robots as well as five hundred but there is no “hive mind” like in other advanced projects by NASA (that apparently were too advanced to actually be pursued): each robot only receives basic instructions and works on its own, carrying out its mission and avoiding other robots, just like termites building a mound.

The team admits that the ideal future scenario will include both an “eye in the sky” central controller and the decentralized, termite-like robots with their own local instructions. While the central controller still needs some working on, the termites seem to be doing just fine. Create globally, build locally: isn’t that what 3D printing is all about?

PHOTO CREDITS: Photo by Eliza Grinnell, SEAS Communications