£556 million of the UK’s budget will be shared among regions in the North of England. The Local Enterprise Partnerships (LEPs) will receive the money under the British government’s Northern Powerhouse initiative. The project seeks to move the UK’s economy away from London, and prepare the country for Industry 4.0.

Inciting innovation

The fund will stimulate projects in transport, the arts and science & innovation, and is split into 11 different LEPs. The “Core Cities” of the Northern Powerhouse proposal, Manchester, Liverpool, Leeds, Sheffield and Newcastle, receive the following shares:

- Greater Manchester £130.1m

- Liverpool City Region £72.0m

- Leeds City Region £67.5m

- Sheffield City Region £37.8m

- North Eastern £49.7m (Encompassing Newcastle)

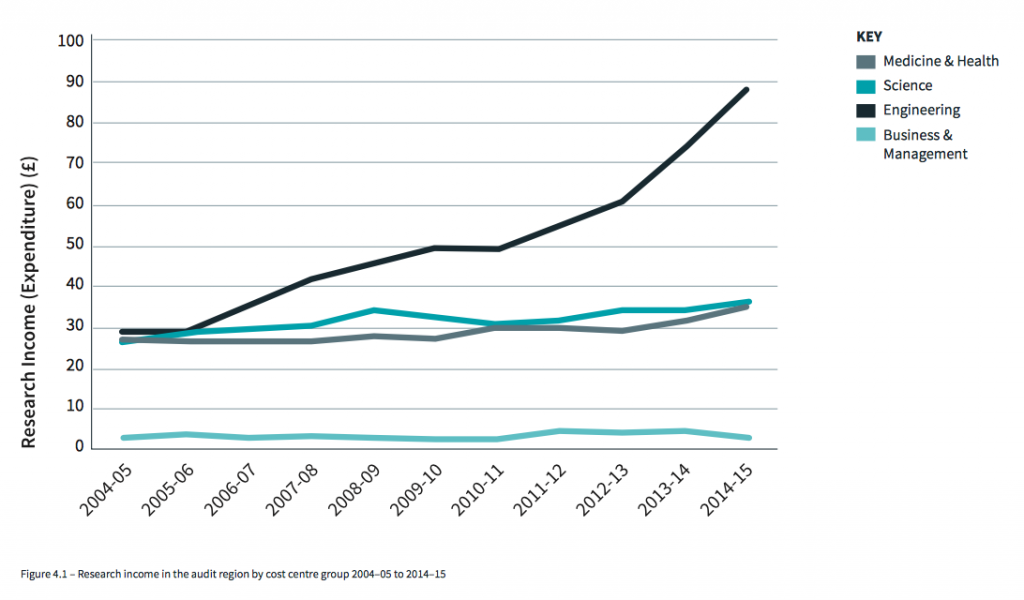

This investment is further bolstered by Wave 1 of the government’s Science and Innovation Audits (SIA).

Identifying strengths for Industry 4.0

The SIAs have been introduced by the UK’s Department for Business, Energy & Industrial Strategy to hone in on areas of expertise within manufacturing, research and development.

Sheffield City region and Lancashire’s combined SIA report puts forward a vision of the “Northern Advanced Manufacturing Innovation Corridor,” already flourishing in part with the support of additive manufacturing. At 3D Printing Industry we’ve looked at many of the companies that are likely to benefit from investment in region.

Polygonica

Starting out life as engineering CAD platform, MachineWorks Ltd. has been based in Sheffield since 1994. Realising their potential to provide Boolean solutions for the 3D printing industry, the company launched Polygonica.

When 3D Printing Industry visited MachineWorks HQ, we learned how Polygonica software tools are now implemented by additive manufacturing market leaders including Renishaw and Stratasys.

3D printable metal powders

Advanced materials company Metalysis is located in Rotherham within the region of Sheffield city. Founded in 2001 the company are investigating new methods for producing 3D printable Titanium powders that could drastically cut the cost of the material.

Defence, aerospace and security

BAE Systems (LON:BA) use additive manufacturing to make aircraft parts for the commercial, defense and aerospace sectors. Although headquartered in Virginia, BAE Systems also has sites in Samlesbury, Preston and Blackburn in Lancashire.

The company were key supporters of the UK government’s SIAs alongside the University of Sheffield and the University of Lancaster.

David Holmes MAI Manufacturing Operations Director, Military Air & Information, of BAE Systems released a statement on the audit’s findings, saying:

The pace of change within advanced manufacturing technologies is constantly accelerating and the UK’s global competitors are well placed to take advantage of the potential benefits that step changes such as Industry 4.0 present.

Further adding:

The SIA priority focus areas are essential to enable UK industry to keep pace with its competition and position the north of England as a continued global sector leader in advanced engineering and manufacturing.

Advanced Manufacturing Innovation District

Already home to car manufacturers Rolls Royce, stainless steel experts Outokumpu and other engineering giants such as Forgemasters, Sheffield’s Advanced Manufacturing Innovation District is set to become an international hub for industry.

Located on the outskirts of the city, the Innovation District has permission to cover 1 million square feet with manufacturing, office and distribution facilities.

Factory 2050 is the first structure on the site built specifically for advanced manufacturing purposes. The building is a 6,730 sq. meter space that can be completely re-configured to suit production needs, and comes readily-installed with Kuka 6-axis robot arm and Automated Guided Vehicles (AGVs).

To sum up the audit of Sheffield and Lancashire Professor Keith Burnet, President and Vice-Chancellor of the University of Sheffield, says

Between the geographies of the Sheffield City Region and Lancashire lies a unique opportunity. One which the UK economy desperately needs. Here lie the components required to equip the UK to deliver the vision of the 4th industrial revolution, Industry 4.0.

As we look towards a third wave of Science and Innovation Audits, and government funded projects such as an International Advanced Manufacturing Park for the North East, it becomes clear that when Industry 4.0 hits, the UK is going to be ready, and the Northern Powerhouse will be front and center.

Featured images shows the University of Sheffield’s Factory 2050, part of the city’s Advanced Manufacturing Innovation District. Photo by: Bond Bryan via sheffieldbusinesspark.co.uk