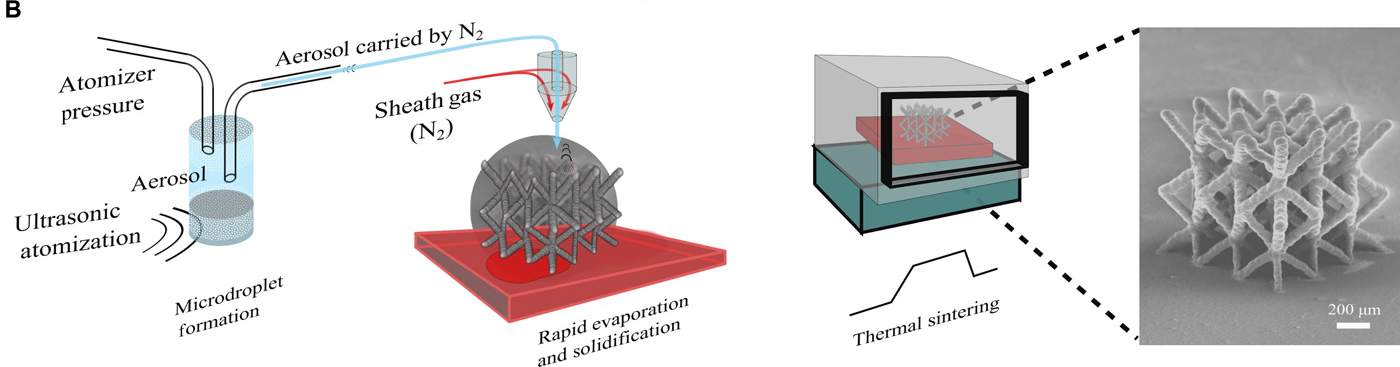

Researchers from Washington State University have successfully 3D printed structures resembling the intricate framework of natural materials. Their process has allowed them to create small structures with impressive strength to weight ratios and control materials on a molecular scale, producing geometries similar to bone and wood.

According to the authors, potential applications of the 3D printed nanostructures include, “tissue engineering, energy storage, strain-tolerant ultralight materials, microfluidic devices, and microelectronic and optoelectronic devices.”

Aerosol Jet printing

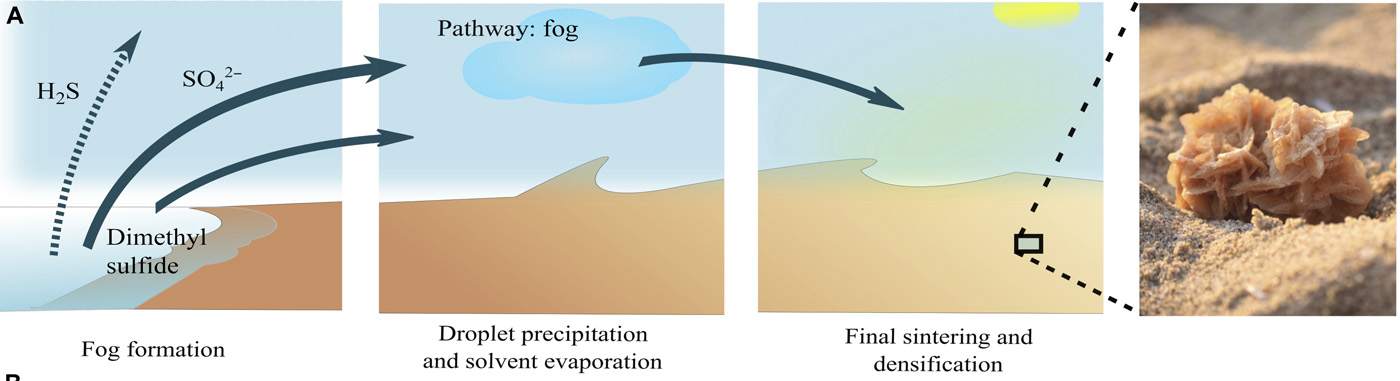

The researchers like their process to the production of an African desert rose.

This natural crystal formation occurs when fog containing sulfur evaporates in African deserts and sticks grains of sand together.

In place of grains of sand, this study uses silver nanoparticles as they are easy to work with.

The silver particles are dispersed in water-based diol solution, “aqueous ethylene glycol“, to create an ink. Following this, the solution is atomised into an aerosol “fog” that is jetted using gas. The structures are then sintered using a heat or light source.

The authors explain,

An aerosolized fog containing droplets from this solution is then generated from the Aerosol Jet technique and carried toward the heated substrate to build a 3D microarchitecture/microscaffold of silver nanoparticles with truss elements in the air that do not require any supporting material or templating

This research utilizes the Optomec Aerosol Jet technique for 3D printing that forms structures using small ink like droplets of metals. The company, based in Mexico, is also the creator of LENS 3D printing technique that uses lasers to sinter metal powders. This method has recently been integrated by a Taiwanese machining company alongside CNC capabilities.

“groundbreaking advance” for nano-material research

Nanoparticles have a molecule size between 1 and 100 nanometers (nm). 1nm is one thousand-millionth of a metre.

What makes this research “an important advance in microscale bottom-up assembly of nanoparticles” is that is can be modified to use other materials of the same size. Ceramics and other metal powder manufacturing could benefit from the technique.

Rahul Panat, associate professor at Washington State University, explains,

This is a groundbreaking advance in the 3-D architecturing of materials at nano- to macroscales with applications in batteries, lightweight ultrastrong materials, catalytic converters, supercapacitors and biological scaffolds. This technique can fill a lot of critical gaps for the realization of these technologies.

Another research paper recently took inspiration from nature to create stronger materials using 3D printing. Researchers from Denmark explored the “brick and mortar” structure of oyster and abalone shells.

“Three-dimensional microarchitected materials and devices using nanoparticle assembly by pointwise spatial printing” is co-authored by Mohammad Sadeq Saleh, Chunshan Hu and Rahul Panat from the School of Mechanical and Materials Engineering at Washington State University. It is published open-access in Science Advances journal.

Vote now in the 3D Printing Industry Awards. Sign up to our newsletter and follow us on twitter.

Featured image shows the crystal formation referred to as a Desert Rose. Photo by Hadley Paul Garland on flickr.