Researchers from the ICMCB-CNRS laboratory and the University of Bordeaux have developed a method of 3D printing phosphate glass via FDM technology.

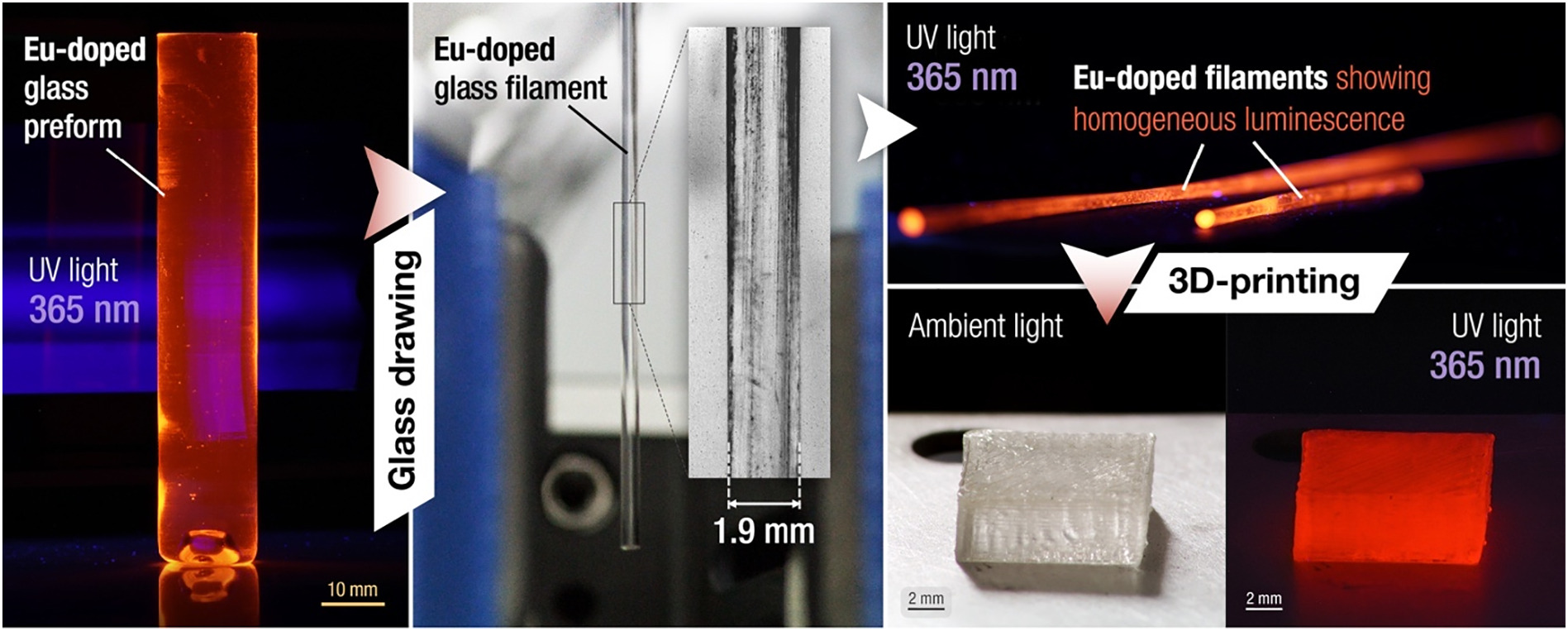

By first pulling the glass filament using a fiber drawing tower, the researchers were able to extrude complex geometries while maintaining the photoluminescence properties of the material. The team believes its direct approach to fabricating the transparent glass gives rise to the possibility of cutting-edge optical components and new biomedical devices.

Phosphate glass

Phosphate glass is an example of optical glass, a material with refractive properties that makes it perfect for lenses, optical fibers, and other components in optical systems. The 3D printing of such material has largely eluded scientists for many years due to unwanted opacity changes and certain crystallization phenomena.

According to the researchers, any semi-successful attempts in the past have been held back by their unfortunate lack of resolution or density. The ability to additively manufacture a high density, sub-millimeter resolution glass object would enable a whole host of low-cost geometrically complex photonic devices – the ultimate goal of the Bordeaux study.

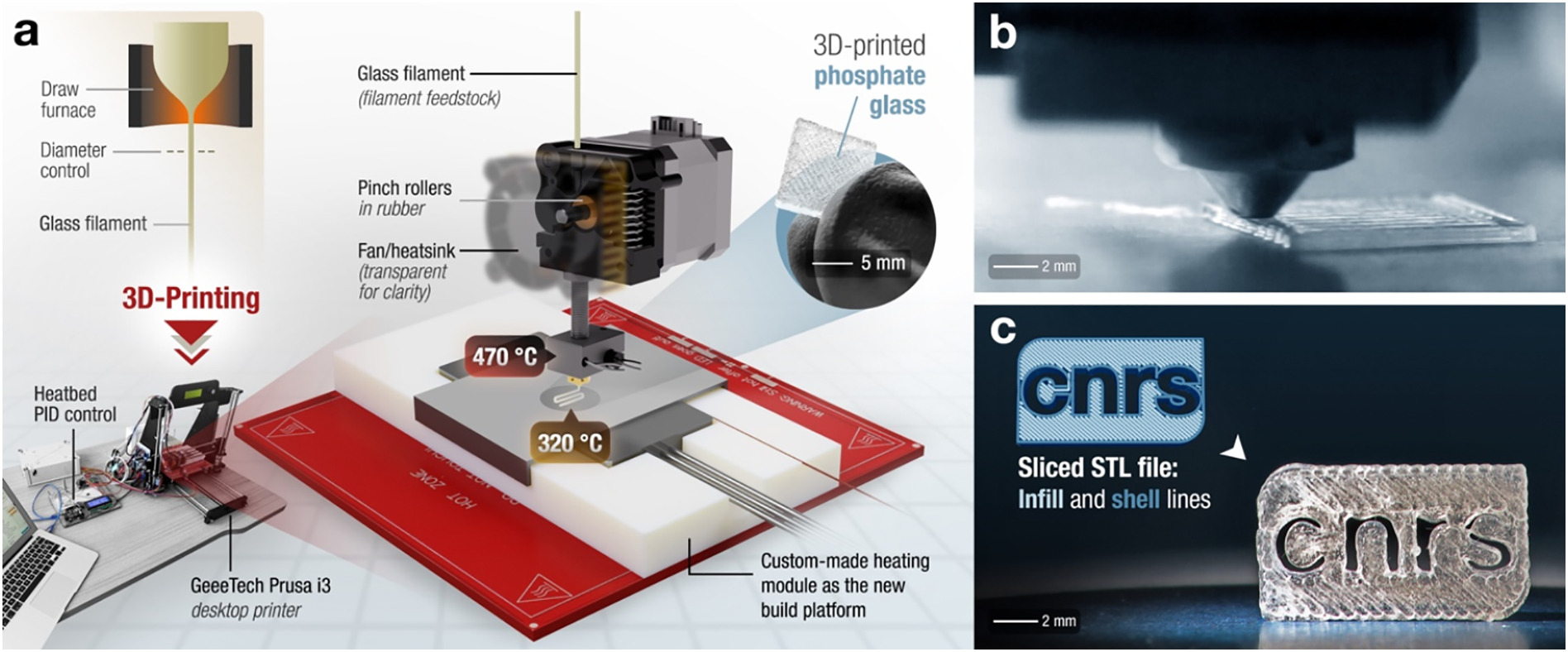

Extruding the glass filament

The first stage of the study involved developing the base phosphate glass filament. The material was specially formulated in a platinum crucible at 800°C before being drawn into a 1.9mm thick rod. Due to the unusually high temperatures required to melt and extrude the phosphate glass, the team had to kit out an entry-level Prusa i3 clone with a custom hot end and print bed. With some heavy modifications, the printer could eventually manage the 470°C nozzle and 320°C bed temperatures required to make the experiment work.

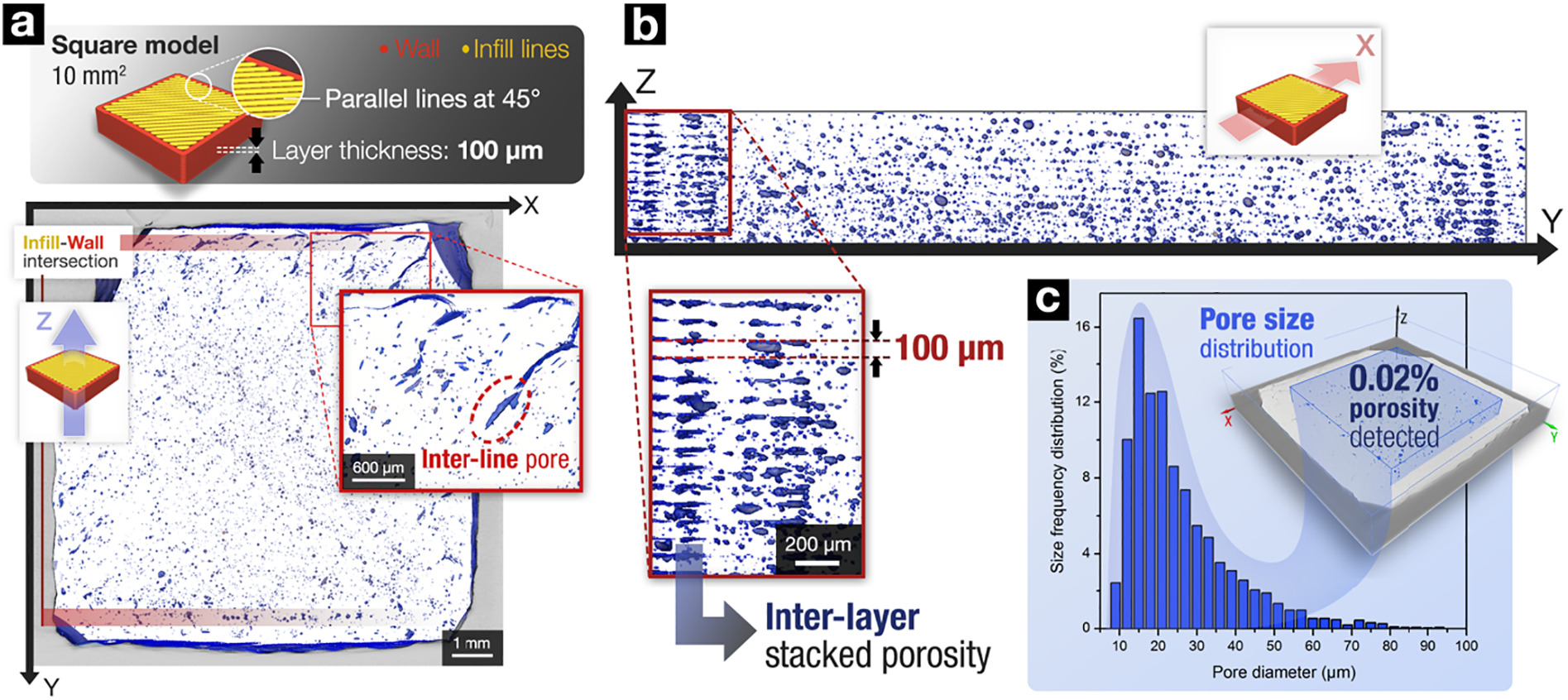

By investigating a number of print parameters in the study, the team was successful in achieving an incredibly high density of 99.98% and avoided unwanted light scattering within the part. A full systematic microstructural characterization was conducted with SEM imagery and X-ray tomography, revealing layer thicknesses in the region of 100 microns and line widths of about 600 microns. The team also found a correlation between inter-line bonding quality and light transmission.

Perhaps the most notable result in the study was the fact that the printed glass structures maintained their optical luminescence properties, meaning they displayed homogenous light transmission throughout. This property is absolutely crucial in any high-tech optical system, so the work shows great potential in providing a cost-effective method of end-use component production.

Further details of the study can be found in the paper titled ‘Direct 3D-printing of phosphate glass by fused deposition modeling’. It is co-authored by Reda Mohammed Zaki, Clément Strutynski, Simon Kaser, et al.

While they have seen great success with their results, the Bordeaux scientists are not the first to experiment with 3D printed glass. Researchers at ETH Zürich in Switzerland have previously 3D printed glass objects using a specialized resin and DLP 3D printing technology. The method utilizes a photopolymerization-induced phase separation within the hybrid resin, creating complex glass parts from a plastic and organic blend.

Elsewhere, in Canada, researchers developed a 3D printable glass suitable for laser and infrared optics applications. The material has a relatively low melting temperature of about 330°C, meaning it can be extruded by a modified entry-level desktop 3D printer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed phosphate glass. Image via the University of Bordeaux.