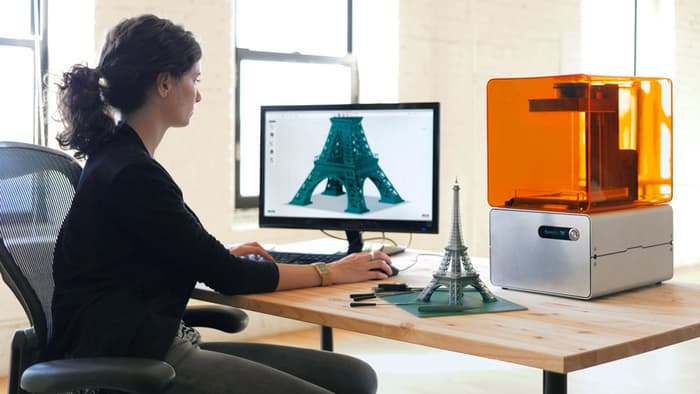

The expansion of 3D printer manufacturers Formlabs will be accelerated by todays news of a $35 million investment. This series B funding comes from Autodesk and Foundry Group and brings total investment in the company to $55 million.

Raising almost $3 million on Kickstarter in 2012, Formlabs was one of the most successful crowd funded projects of the time. This latest round of financing also includes further investment from DFJ Growth, Pitango Venture Capital and Pascal Cagni.

When Formlabs co-founder and CEO, Max Lobovosky began this journey he was still a student. Lobovosky met fellow founders Natan Linder and David Cranor at MIT. The trio were all taking Neil Gershenfeld’s hugely influential ‘how to make (almost) anything’ course. Gershenfeld’s work at MIT and his Center for Bits and Atoms is credited with a key role in the spread of Fab Labs across the globe.

Advice for starting a company

Lobovosky has advice for founders planning to follow in his footsteps, “Work with people that have done it before, at least as an advisory, if not working on the project,” directly. He adds, “When you set the time for estimated delivery, double it. Make sure you have plenty of buffer. Things always take longer.” Lobovosky learned this the hard way, some of the Form 1 Kickstarter backers had to wait until December 2013 to receive their printers.

This lastest deal includes a board seat for Foundry Group co-founder Brad Feld. “From the moment of its founding, Formlabs saw the opportunity in making professional desktop 3D printing accessible and was a key pioneer in the category,” said Feld.

Feld’s view that, “While the excitement and hype around consumer 3D printing has waned, the professional 3D printing category has had unabated demand,” echoes other industry leaders. Both Stratasys and 3D Systems have recently expressed a similar sentiment and Stratasys CEO Ilan Levin said earlier today the 3D printing industry is, “maturing and evolving.”

The importance of strategic partnerships

Lobovosky said the investment would enable Formlabs to, “Continue to grow the stereolithography business and bring new tools to the world to advance our goal of making digital fabrication more powerful and accessible.” To achieve this part of the $35 million will be used to increase the number of employees from the current level of 190 to 300. Hiring will take place throughout 2017.

The investment will also be used, “To develop more powerful tools to enable anyone working with 3D content to create remarkable things,” said the CEO.

Autodesk’s investment and partnership with Formlabs will undoubtedly play an important part in this strategy. Autodesk’s software is widely used by designers and under the leadership of CEO Carl Bass the company has repeatedly demonstrated it’s commitment to innovative technology.

The partnership means that Formlabs will have a strong ally in the increasingly competitive 3D printing landscape. The relationship should allow the 3D printer manufacturer to benefit not only from the investors deep pockets, but also access some of Autodesk’s millions of users.

Formlabs is a privately owned company, which means it is not subject to the same reporting requirements as publicly held businesses. A typical finance journey might see a company initially raise money from friends and family, or early stage angel investors (in this case Kickstarter), then a series A round with Venture Capitalists to bring the product to market. Formlabs raised $19 million in 2013 during such a round to rollout the Form 1 3D printer.

The series B round is commonly used to expand operations and increase market share. Further private financing rounds may follow, or the company go public and undertake an Initial Public Offering (IPO).

IPO’s are advantageous in that they bring in additional finance and can raise the profile of a company. They also bring stricter reporting requirements and greater scrutiny. As a private company Formlabs does not, and does not have to, disclose detailed breakdowns of revenue. The most recent reports suggest the company is shipping 1,000 3D printers per month.

Creating a 3D printing ecosystem

With the announcement in May 2016 that Formlabs had acquired 3D printing community Pinshape, the company followed a similar path of Stratasys who acquired Thingiverse when they purchased MakerBot in 2013.

At the time of the acquisition Formlabs said they did not plan to charge users for access to premium models. “The model of iTunes for 3D printing is simplistic and less interesting than the GitHub model of a collaborative place to build things,” explained Lobovosky. Anyone who has watched Luis Lopez and J. Clay Tweel’s entertaining documentary, ‘Print the legend’ will already be familiar with this difference in approach.

Whether Formlabs will be able to convert Pinshape designers to 3D printer customers remains to be seen. This strategy requires careful handling to avoid a revolt by the community and is typically a long-term play. In todays earnings call Stratasys confirmed that they do not expect to see significant revenue from their $100 million purchase of GrabCAD for several years. Potential suitors for GrabCAD, sometimes referred to as GitHub for mechanical engineers, included Autodesk and Adobe.

One of early investors in GrabCAD, David Skok, believes these types of social networks have a clear value for investors. When members of the community upload new files this adds weight to the websites reputation, and subsequent ranking, with search engines like Google and creates, “a viral effect to increase the community.”

Integrating community, software and hardware may enable Formlabs to establish a 3D printing ecosystem. It is a long-term approach familiar to their strategic partner who offer students free access to design software, understanding that this group will make buying decisions later in their careers.

As Lobovosky says in Print the legend, “If you’re really building a company on a really long-scale, the only advantage you have is the culture. Whatever it is that’s intrinsic to the organization. That, in some sense, is the most important thing.”