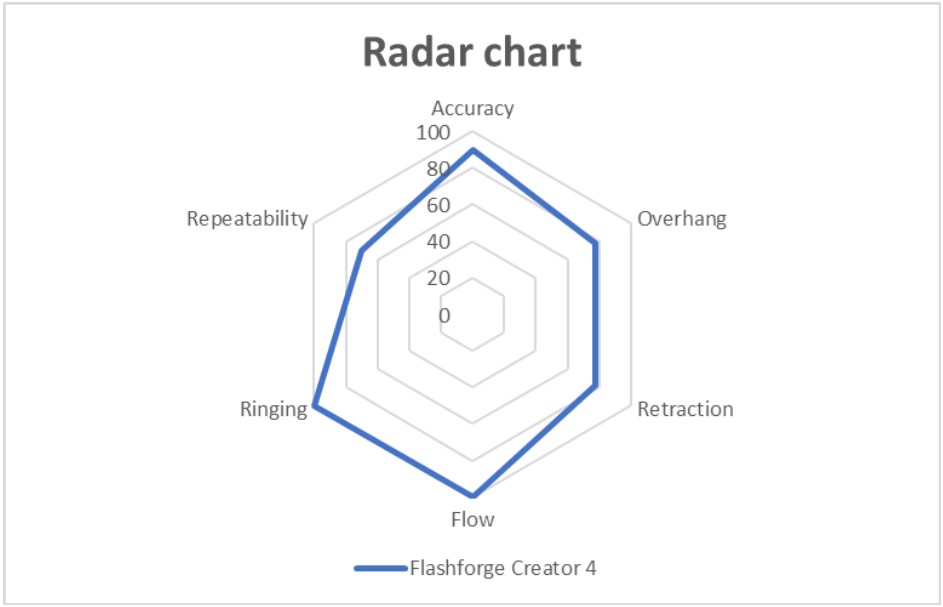

In this article, the 3D Printing Industry engineering team reviews the FlashForge Creator 4S.

FlashForge USA is an American company well known for FDM 3D printing systems. 3D printers made by the company include both professional machines and consumer-level printers. Their newest 3D printer series is the Creator 4 & 4S. These professional machines utilize its three separate interchangeable nozzles, allowing access to a wide range of materials.

Starting from an affordable $12,900, the Creator 4S is a 3D printer designed for use in professional environments such as high-level engineering fields, automotive or aerospace industries, and tech development due to its large Z-axis size. The machine comes in two available configurations: Creator 4S and Creator 4A. Each offers its own functionality and area of application. Previous releases from FlashForge USA, such as the Guider and Creator series, have been very popular with both professional and consumer clients.

The Creator 4 was released in October 2021 and can be ordered from the FlashForge USA website.

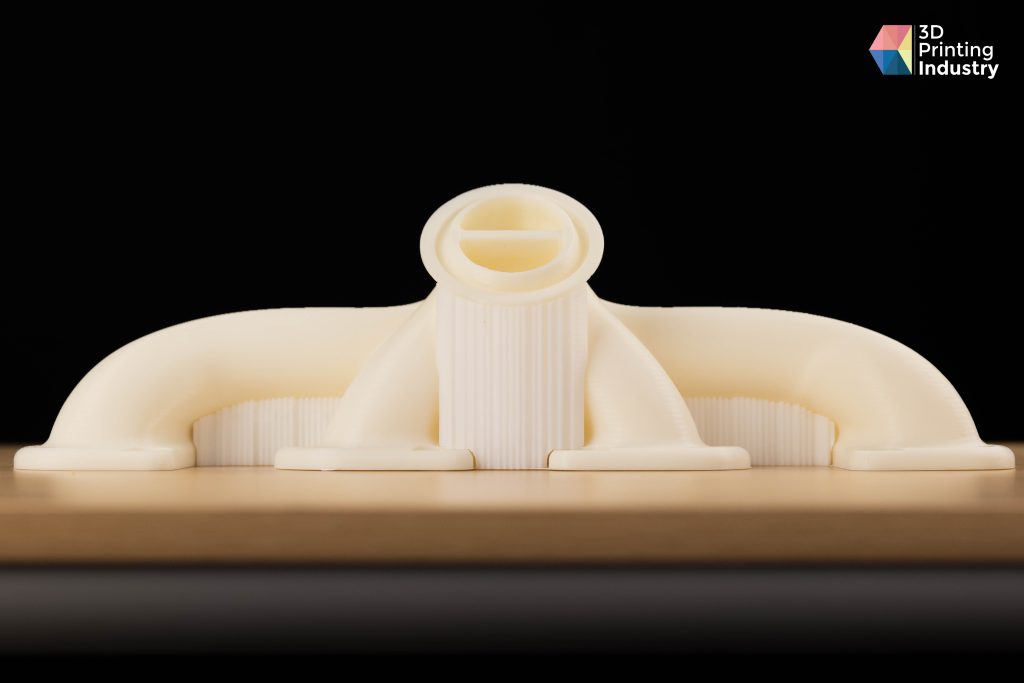

FlashForge USA has released this printer to provide a large build volume, IDEX (Independent Dual Extrusion) capable machine. This system opens up multiple opportunities for printing modes. Multiple models can be 3D printed coincidentally while using different materials. Alternatively, the nozzles can be used to print one part with two material properties, and dissolvable supports or added color can be achieved with great accuracy.

FlashForge Creator 4S 3D Printer. IDEX Printhead arrangement. Photo by 3D Printing Industry.

Other features of this printer include a large build volume (400mm x 350mm x 500mm), high-resolution capability, three nozzles that allow for complex filament printing, and extensive material options. Inevitably there are also some shortcomings with this printer; these are not many but merit consideration when buying this machine. Profiles for some materials are absent from the slicer that were previously available on the Flashprint software; we understand a software update will tackle this temporary issue.

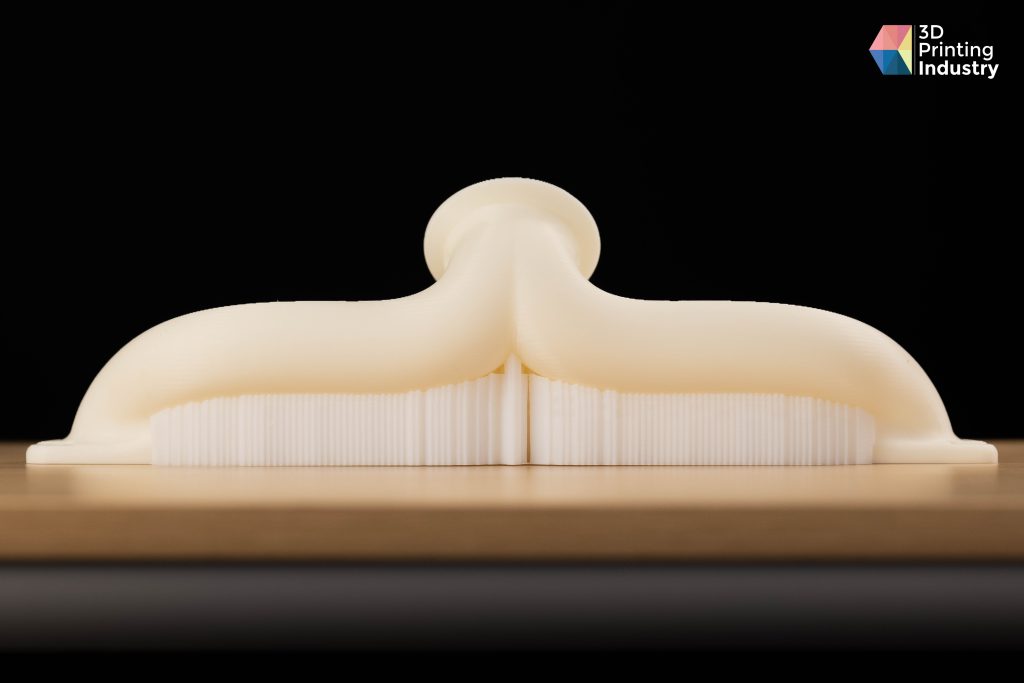

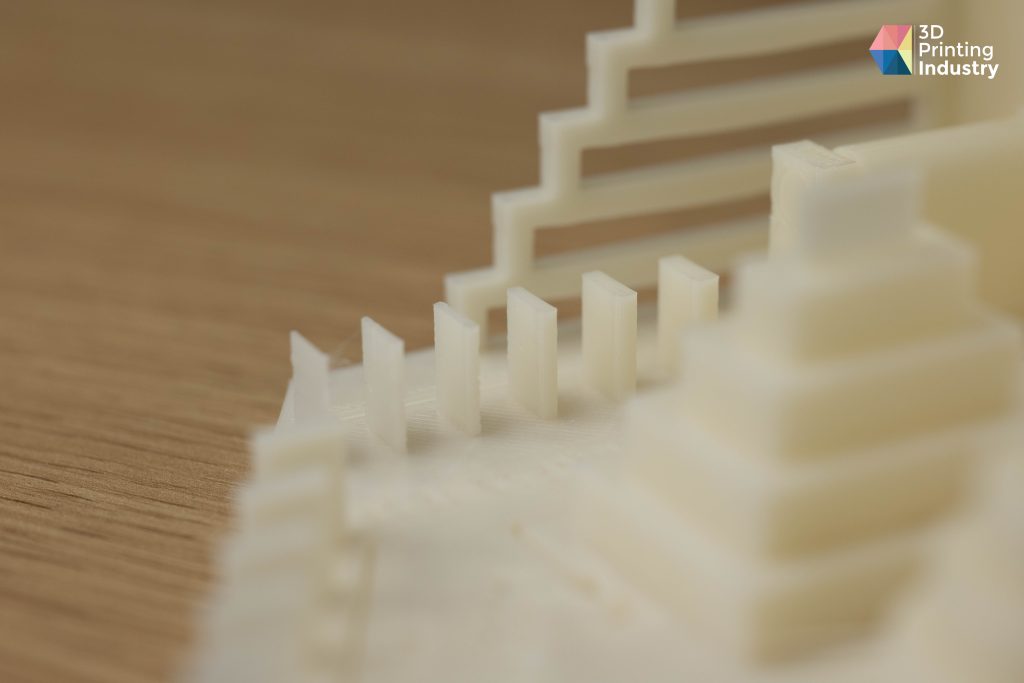

When printing using the entire build volume, the nozzles collide, pressing on the filament unload lever, stopping any extrusion at this extreme of the Y-Axis. This issue can be seen during the printing of the width test where the -Y side is 3D printed shoddily.

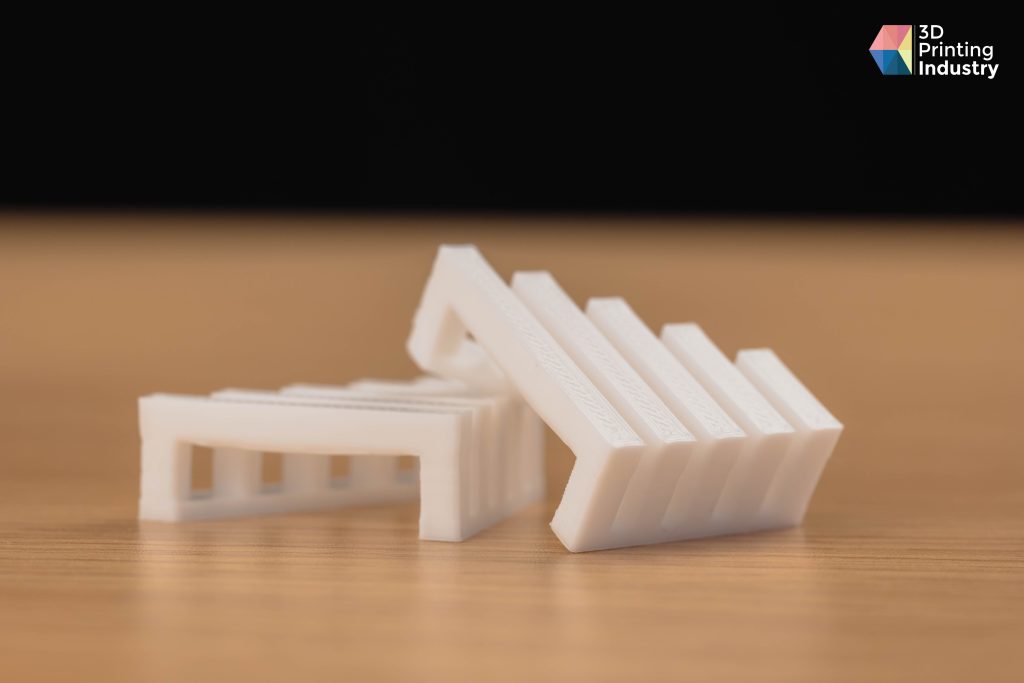

FlashForge Creator 4S 3D Printer. Width Test Errors. Photo by 3D Printing Industry.

Overall, this printer has been a brilliant machine, and we will elaborate further on this using the results collected during our engineering tests.

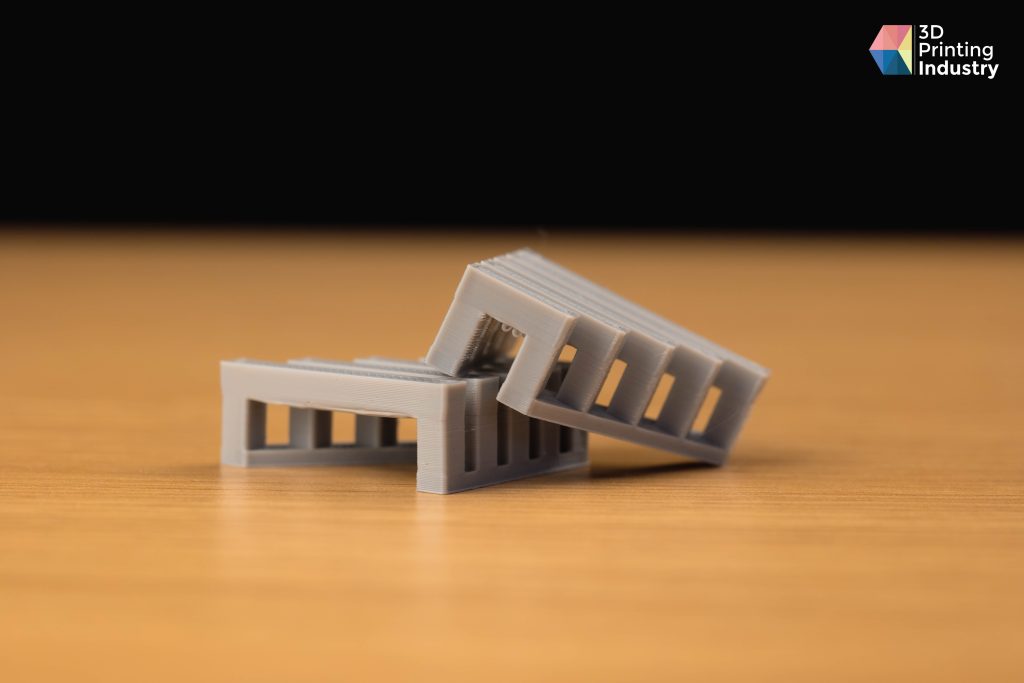

When testing industrial printers, we have a procedure to determine the critical strengths and weaknesses. These 3D printing tests allow us to collect data on repeatability, overhangs/bridges, adhesion, and precision.

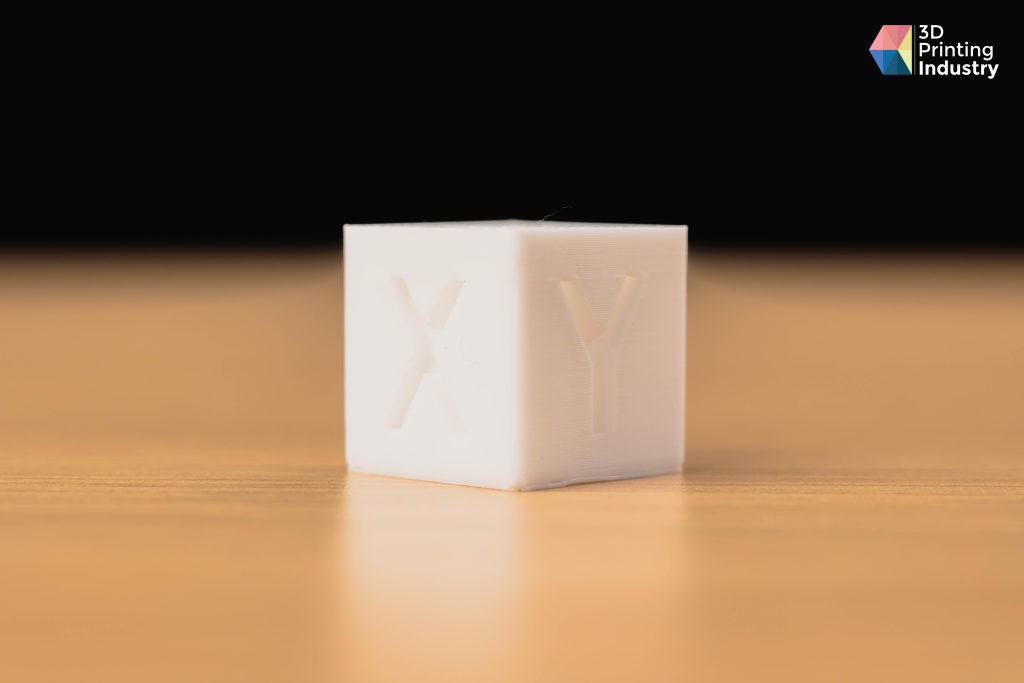

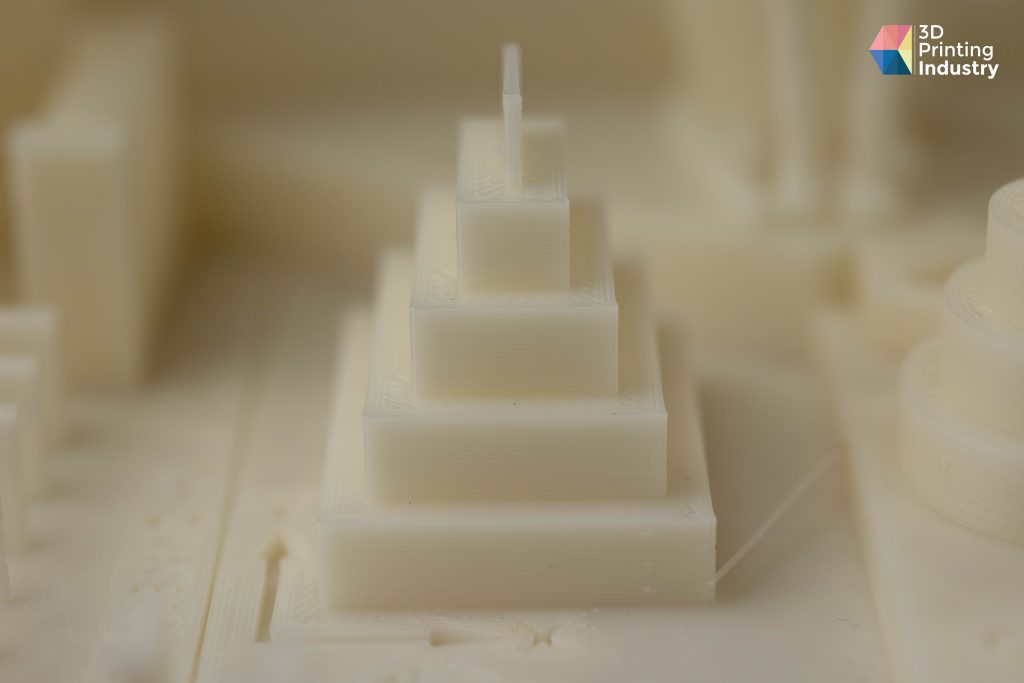

FlashForge Creator 4S 3D Printer. Calibration Tests. Photo by 3D Printing Industry.

Key features of the FlashForge Creator 4S

The main attraction of this machine, as mentioned, is the multiple nozzle options and IDEX dual printhead arrangement. These configuration options, paired with the large build volume, give the printer bountiful production opportunities. The dual extruders can be programmed to do many things depending on the use of the printer.

Dissolvable supports will be helpful if the users 3D print parts with complex internal geometries. If the 3D printer is prototyping numerous designs, the two printheads can print simultaneously layer by layer, halving the time taken to produce prototypes. A single part could also be printed with multiple materials or colors. This option is useful for production-grade prints as this can produce robust and clean results.

FlashForge Creator 4S 3D Printer. Intake V8 Engine manifold printed with dissolvable HIPS supports. Photo by 3D Printing Industry.

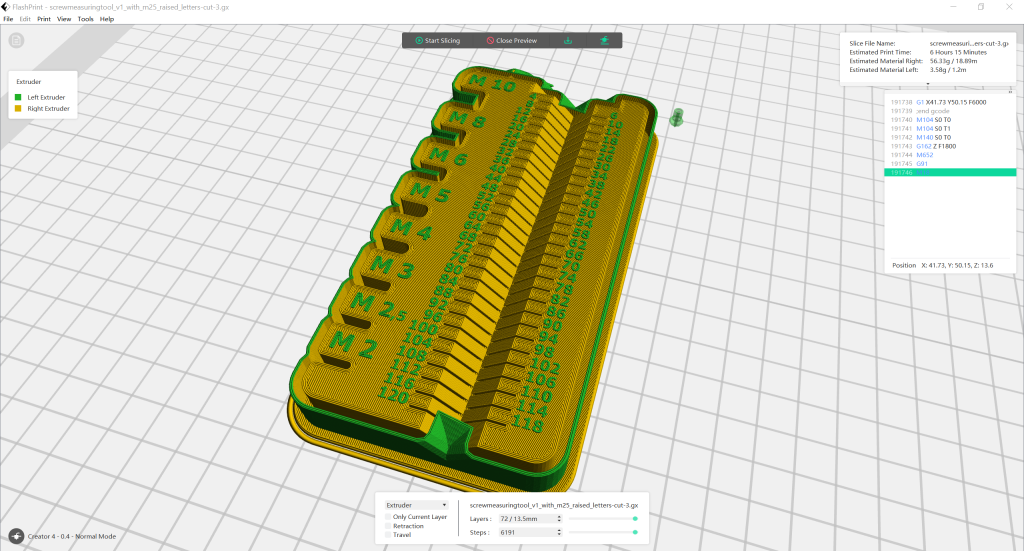

The FlashPrint 5 slicer is extremely easy to use. It comes with all the necessary features and parameters that a 3D printer professional would come to expect from a machine in this range. The UI & UX is clear and concise, which aids in the overall 3D printing experience when using this machine.

Minimal calibration is needed between prints on this machine as the left nozzle is equipped with a magnetic proximity sensor. This sensor generates a magnetic field and can detect interruptions when in contact with the metal build plate. This is a precise way of determining where the bed is located and can create a perfect mesh layout of the built plate’s position for an accurate first layer.

First Impressions of the FlashForge Creator 4S

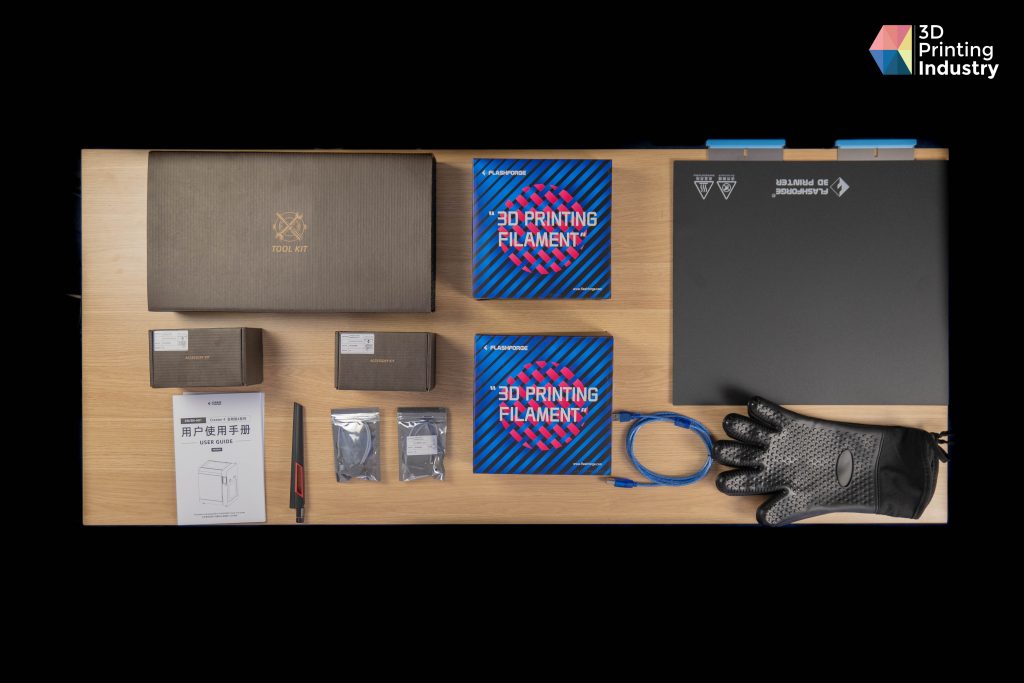

The 3D printer’s packaging is the same as expected from any FlashForge USA machine. The printer’s exterior is sandwiched between the crate using large foam sheets. This packaging protects the machine from any major hits and movements. Inside the machine, the Z axis is also protected similarly. A large block of foam containing the additional nozzles and tooling required for use is located under the bed holding it in place. The dual printheads are also cable-tied to the chassis to minimize disruption during transit.

In terms of peripherals, the Creator 4 is well-prepared with all the extra parts needed for operation. These parts include 1kg ABS spool,1kg PLA spool, nipper pliers, screwdriver, unclogging pin tool, Allen wrench, 2* lubricating grease, USB pen, leveling card, diagonal pliers, scraper, heat insulating gloves, cleaning brush, thermal paste and 5* fuses.

FlashForge Creator 4S 3D Printer. Included peripherals. Photo by 3D Printing Industry.

The printer can be purchased in 3 variations, The differences being the nozzles included in the purchase. There are three models of hotend with this machine.

Extruder-F does not come stock with the machine and is used for printing flexible materials and dissolvable supports and has a filament diameter of 2.85mm. It can reach a temperature of 265°C and print at a speed of 100mm/s. Supported Filaments include TPU85A / TPE / TPB / TPC.

Extruder-HT comes stock with the machine and is used for printing engineering materials. It can achieve a printing speed of up to 200mm/s and a regular filament diameter of 1.75mm. This nozzle can heat up to 320°C and has many material options, such as PC / PA / PP / PETG / ASA / ABS / PLA / PC-ABS / PAHT.

Extruder-HS comes with the machine (Creator 4S) and is used to print carbon fiber and other composite materials. It has a printing speed of 150mm/s and uses 1.75mm filaments. This hotend has a hardened steel nozzle and is used for specialist materials, many of which have a high melting temperature. Following this, the nozzle can reach 360°C. These materials are PACF / PET-CF / PP-CF / PA-GF / PC-ABS / PP-GF / PPS-CF / PPS.

As listed above, the three nozzle options can be used to print almost any material. This unit is a big benefit as it has many applications in different industries.

The large build volume with an impressive X400mm x Y350mm x Z500mm is also extremely suited to industrial prototyping and production.

FlashForge Creator 4S 3D Printer. Multiple prints showcasing ability. Photo by 3D Printing Industry.

FlashForge Creator 4S target market

As discussed previously, this printer is in no way a casual desktop unit. This printer is aimed at professionals and businesses. To utilize this printer’s full potential, a proficient technician is advantageous to the success of prints. Therefore we do not recommend this printer for beginners; however, previous experience using desktop printers will translate to this larger machine.

The quality of this machine matches the target market as its build is predominantly black metal, aluminum, and plastic panels. This printer is at the top end of its bracket before entering the industrial segment of the 3D printing industry.

FlashForge Creator 4S Software Review

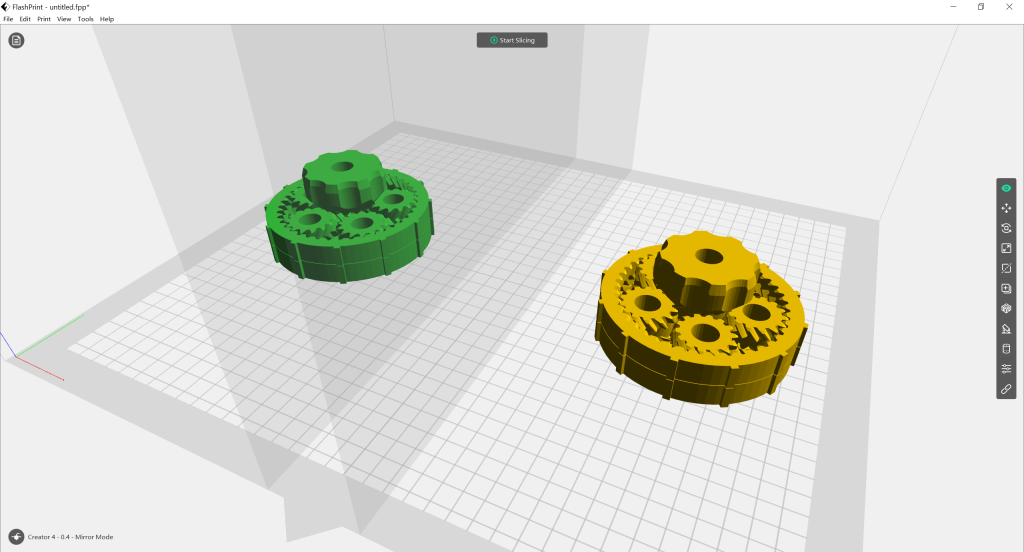

The Creator 4, much the same as the FlashForge fleet, uses FlashPrint 5 (at the time of this publication). Different profiles can be set using this software; however, the full catalog of materials is unavailable to this machine as they are with the Guider & Creator 3.

This software is straightforward and comes with all the tools and perimeters needed to complete complex and detailed prints.

The two nozzles are clearly set out in the UI, and selecting the appropriate materials loaded into the machine is intuitive. Our engineers had no issues using this slicer and stated it was one of the best in its range.

FlashForge Creator 4S 3D Printer. Software Photos. Photo by 3D Printing Industry.

3D Printer Benchmarking on the FlashForge Creator 4S

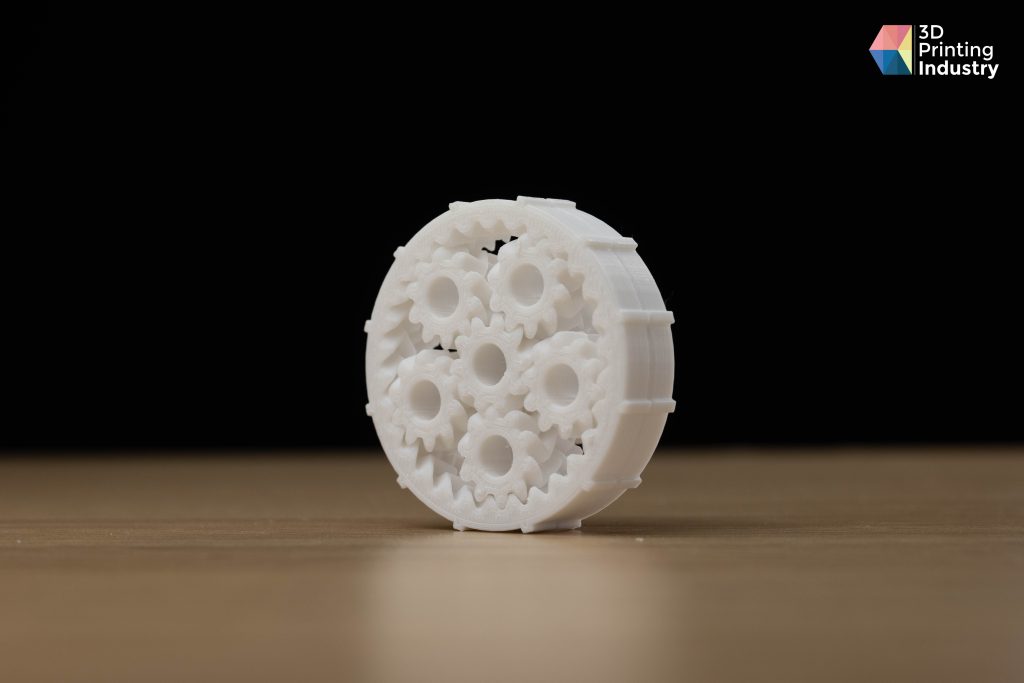

The first print on a new machine is always the file on the USB key. This file is usually optimized for the printer and should produce perfect results. The file loaded on this printer used PLA from a single extruder to produce a small mechanical part. This part was printed perfectly.

The next print was the Benchy, a standardized test throughout 3D printers to test many parameters in one model. This print was a success and had an impressive resolution for an FDM printer, resulting in an average deviation of 0.0454mm. The average for this test is 0.15mm.

FlashForge Creator 4S 3D Printer. Benchy tests. Photo by 3D Printing Industry.

Once this test is complete; our engineers can move on to more in-depth testing, which will give us results for individual areas of weakness or strength.

FlashForge Creator 4S 3D Printer. 3DPI Tolerance. Photo by 3D Printing Industry.

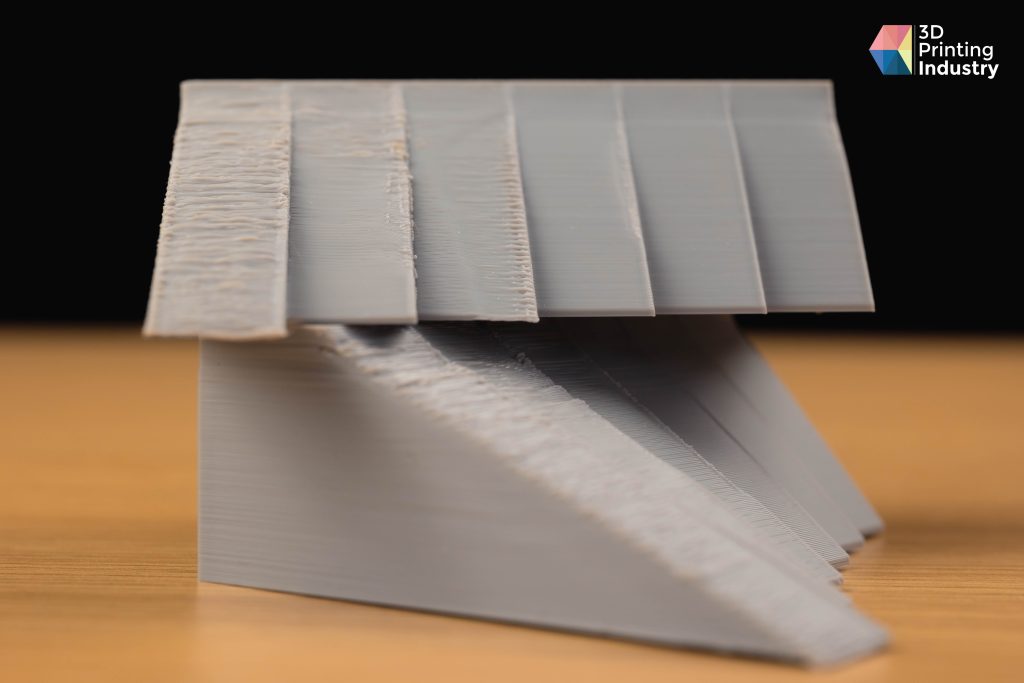

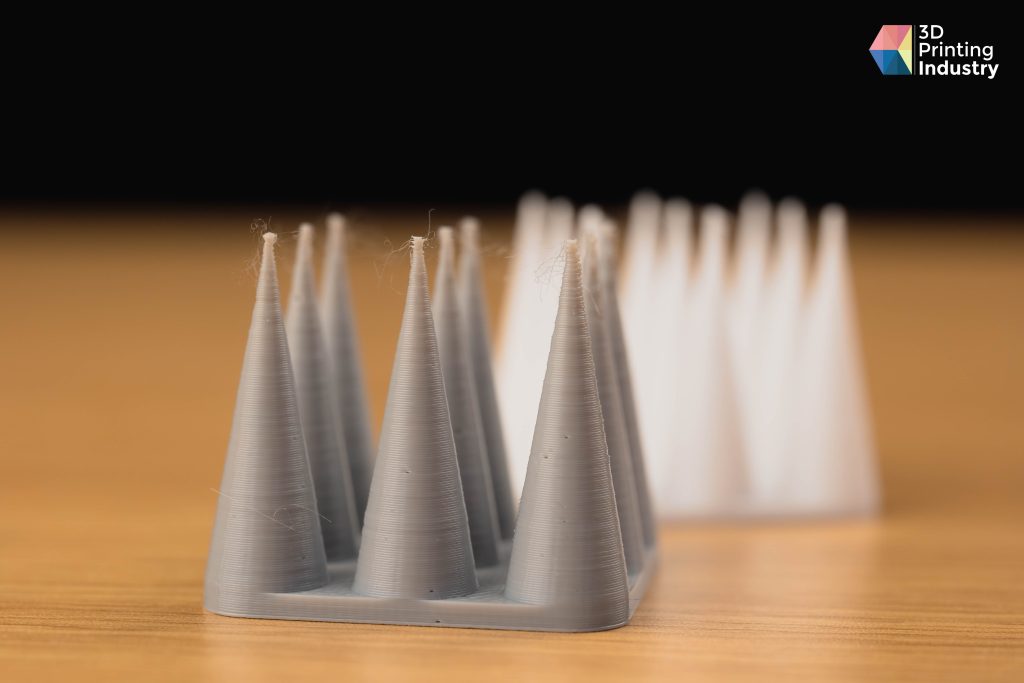

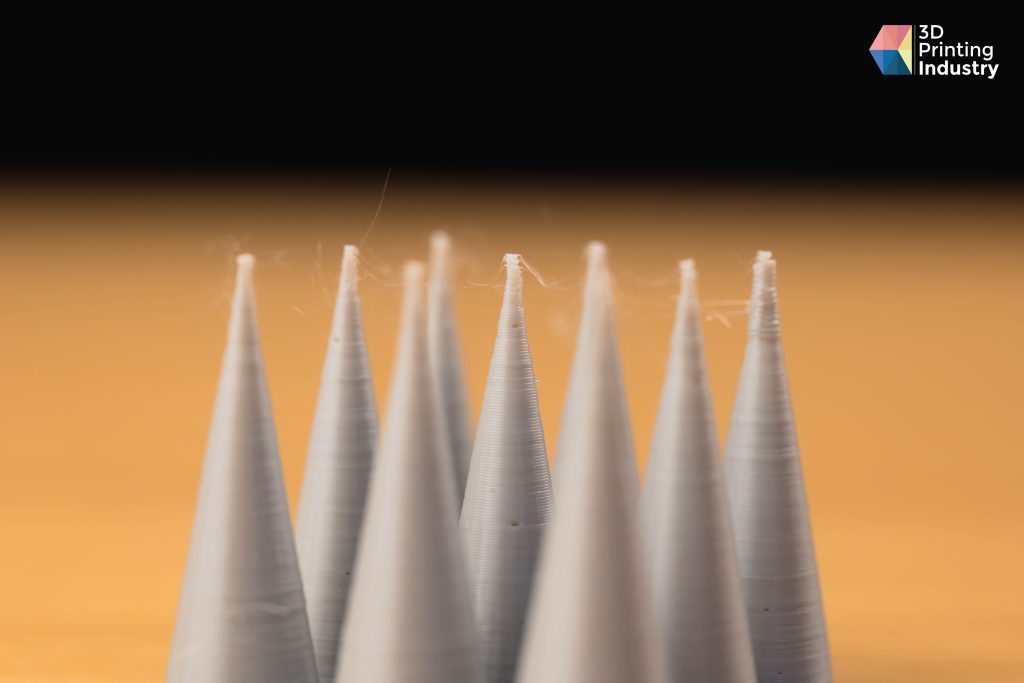

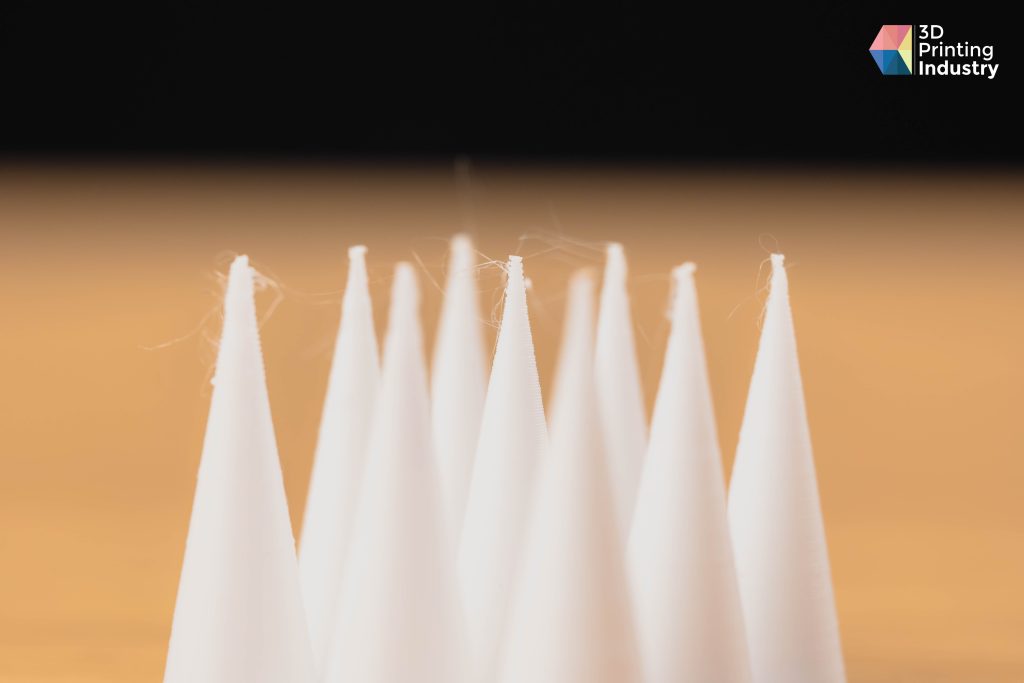

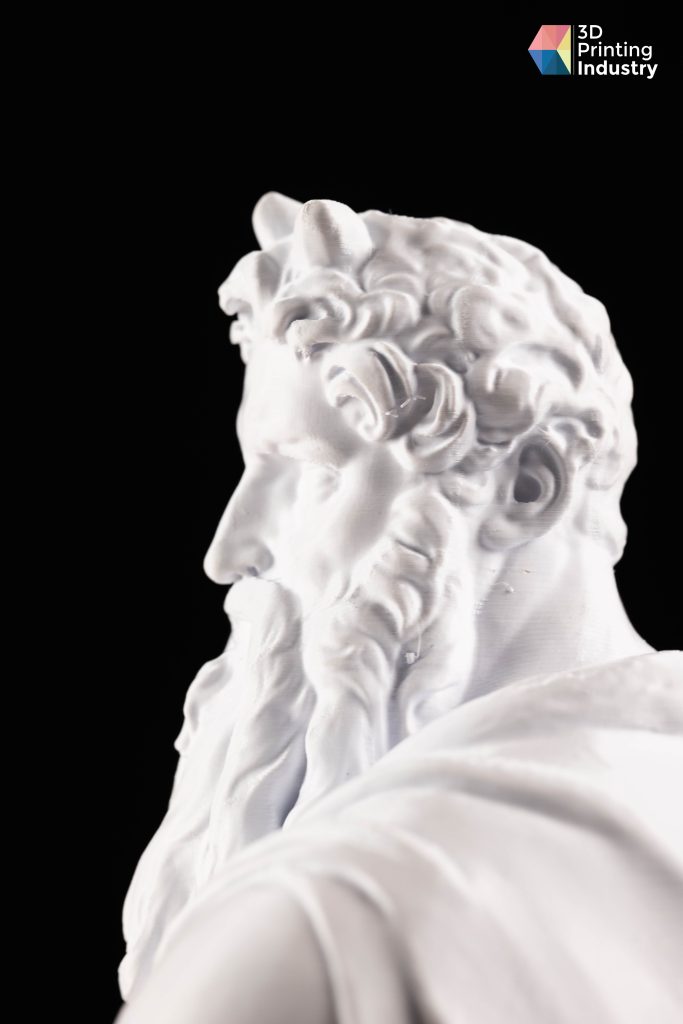

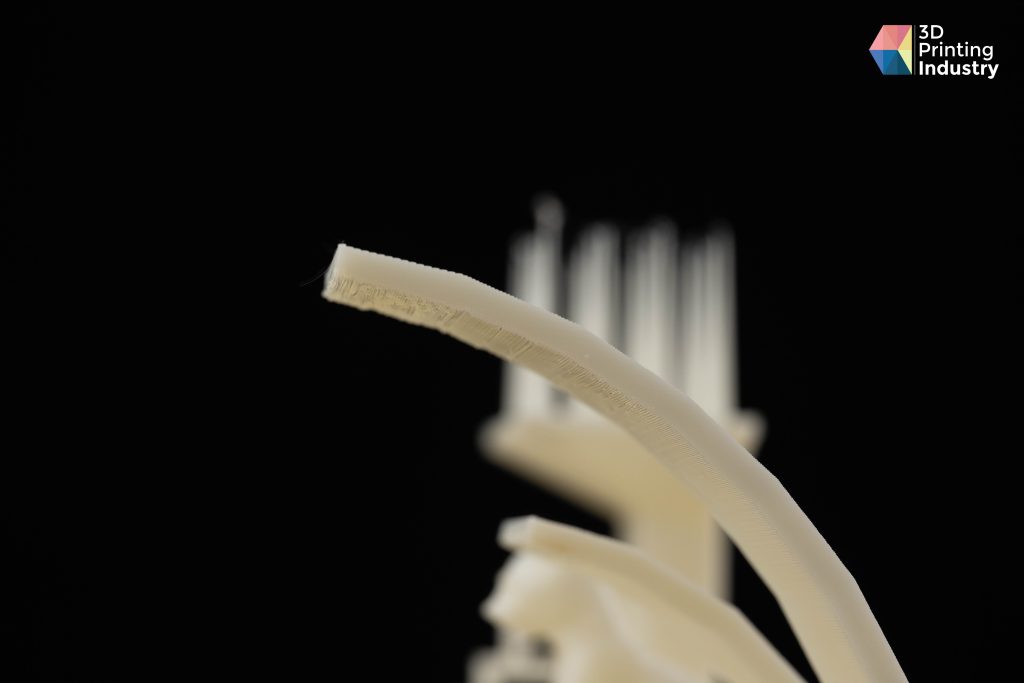

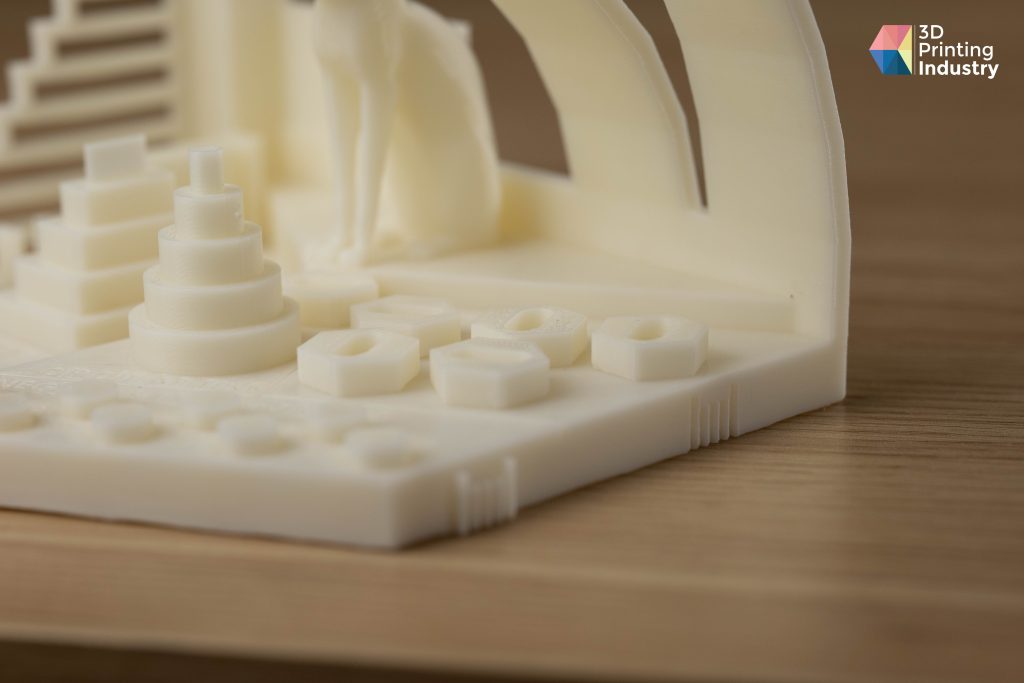

The next test we will carry out is the 3DPI benchmark test. This gives us an overall score using all the basic models in one complete part. These tests are usually printed in a complex filament such as PETG or ABS, as machines often struggle with these materials. On this occasion, we decided to print the 3DPI test using ABS to show how well the printer behaves with the material. Each section of the 3DPI benchmark is individually measured and scored based on factors such as dimensional accuracy, surface quality, and structural integrity.

The Creator 4S scored 86.12/100, an excellent score for an ABS print. The spike section printed perfectly on this test, and there are no deviations or bending visible; this may be due to adequately placed fan ducts blowing cool air onto the plastic.

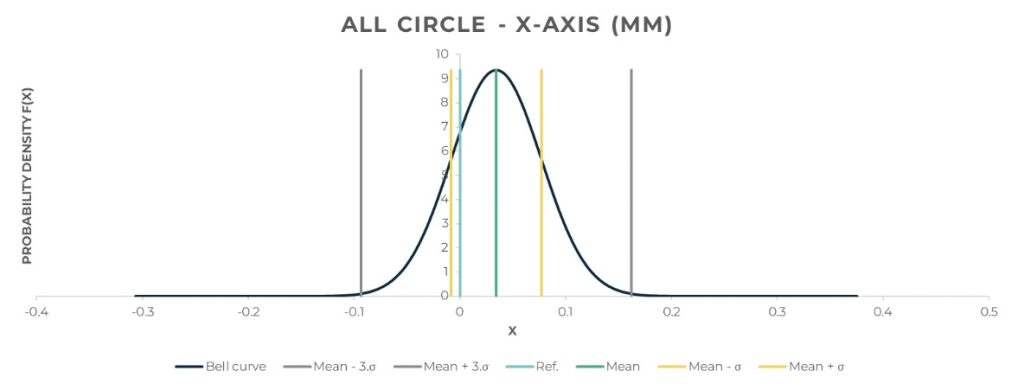

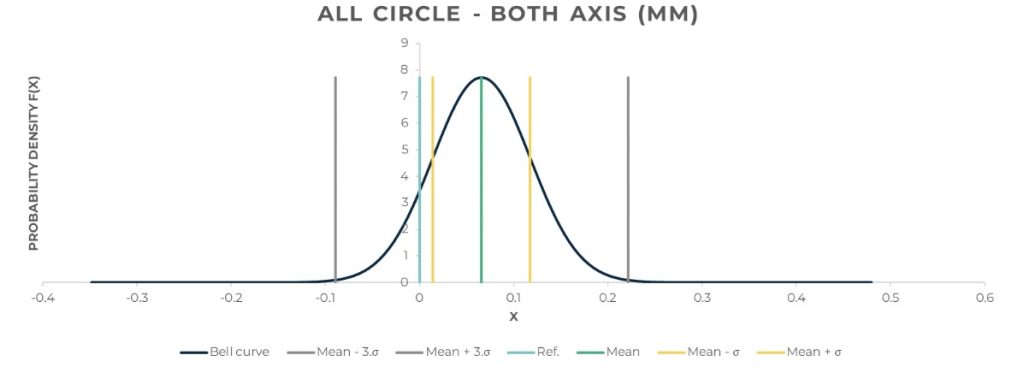

The circular trajectory is also a useful test for a large cartesian printer, as the jerk from the belts stopping and starting can cause inaccuracies in geometry.

The parts printed are composed of three circular sections of 100mm, 65mm, and 20mm.

These tests suggested that the larger the circle, the less accurate the printer becomes. For example, the average difference for Circle 1 (20mm) on the Y-axis is 0.0253mm, while for the X-axis, the figure is 0.0217mm. The average difference for Circle 3 (100mm) on the Y-axis is 0.1433mm, while for the X-axis, the deviation is 0.0433mm. The Y-axis performance worsens as the size of the circle increases. This result seems normal because, on a cartesian printer, the Y-axis must support all the inertia of the X-axis with the gantry, the two stepper motors, and each of the printheads. This result continues in the other circle models, each iteration producing worse results on the Y-axis.

FlashForge Creator 4S 3D Printer. Circle trajectory tests. Photo by 3D Printing Industry.

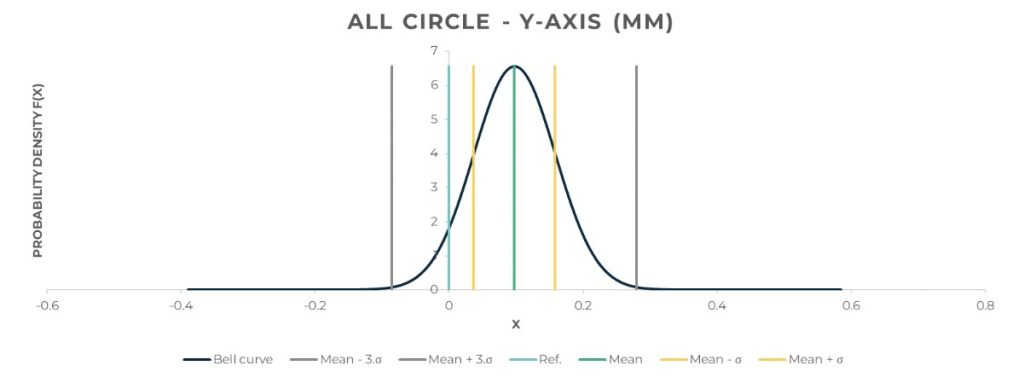

Below are the bell curves showing the results over all three circles in the test. These show the statistics for the X-axis, Y-axis, and both combined. Overall the mean of the standard deviation of all the circles is 0.0517mm, which is higher than ideal. The average of deviations is better, with a score of 0.0659mm. This results in an average deviation of 0.0344mm for the X-axis, while the Y-axis gets a result of 0.0973mm. These results are not as good as we had hoped, and an option to adjust E-steps on the printer may be a beneficial feature for FlashForge USA in the future.

FlashForge Creator 4S 3D Printer.Bell curves from circle trajectory. Photo by 3D Printing Industry.

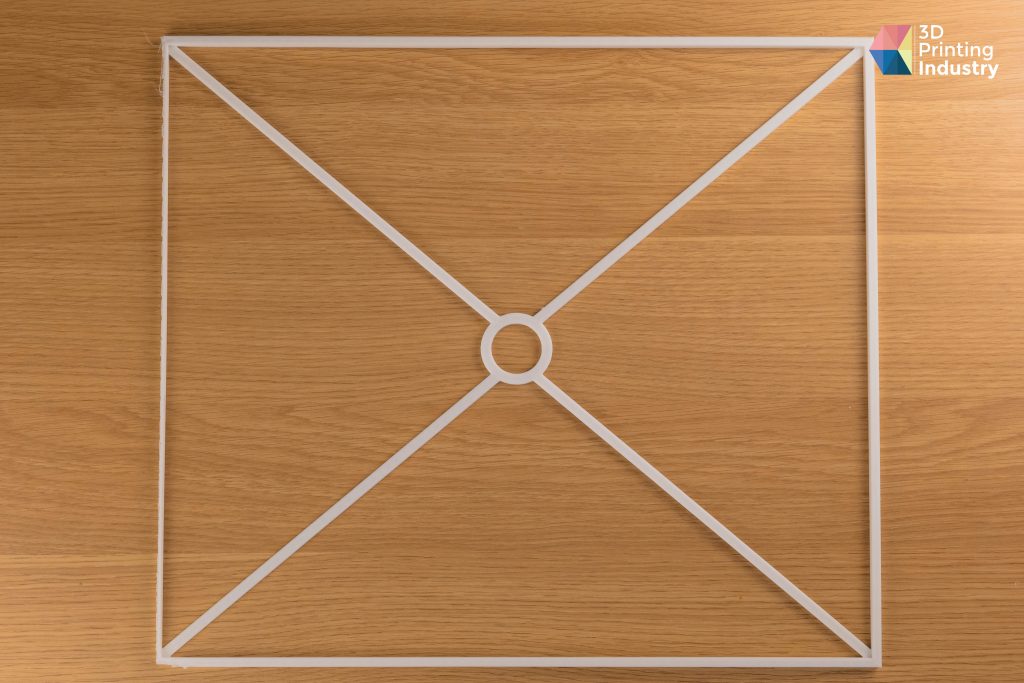

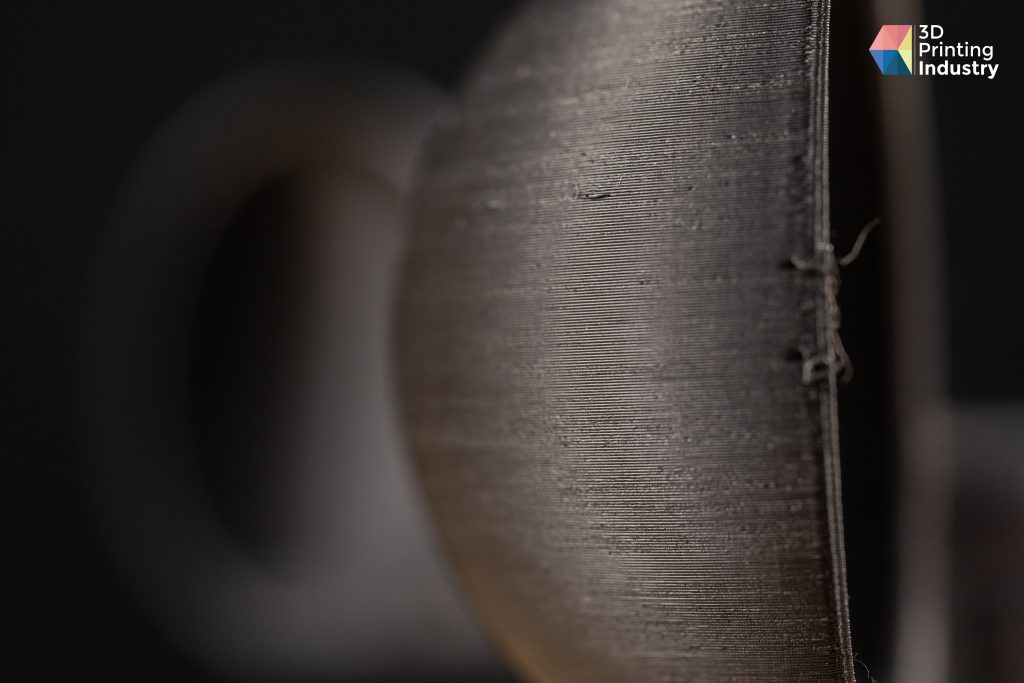

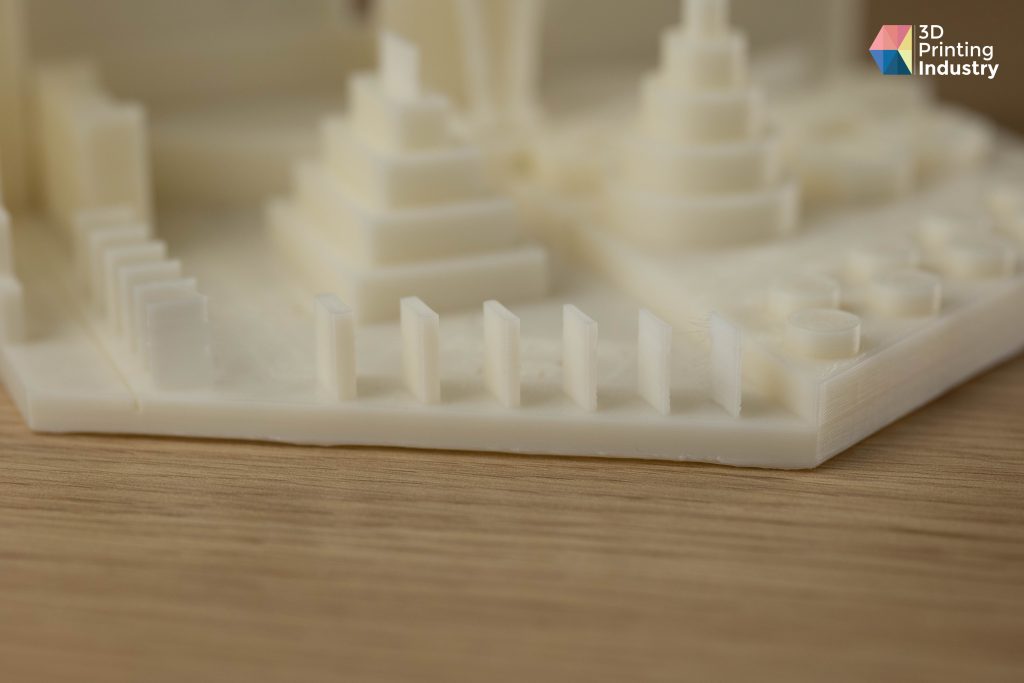

Width testing is also carried out. These simple tests are required to confirm the manufacturer’s build specifications. The max height given, 500mm, cannot be confirmed from our tests as we could only reach up to 495.8mm.

The same goes for the width of the workspace. Specified dimensions were 400mm x 350mm. First, the slicer does not accept models that fill the build plate. The maximum the software would accept was 398.21mm x 348.43mm, which worsens as the actual printed dimensions are 396mm x 348.4mm. Compared to the advertised volume, this is relatively poor.

The reason for this result is both software & hardware related, as when both nozzles are in movement on the X boundary, the filament loading springs make contact, resulting in no filament being drawn out. This is a significant oversight on FlashForge USA’s part and is a disadvantage for this machine.

All results were measured with a vernier caliper or a micrometer up to ±0.004mm. The results above are very encouraging and inform us well on the printer’s accuracy, the downside being the issue with the colliding extruders, which we recommend FlashForge look into for future sales of this machine.

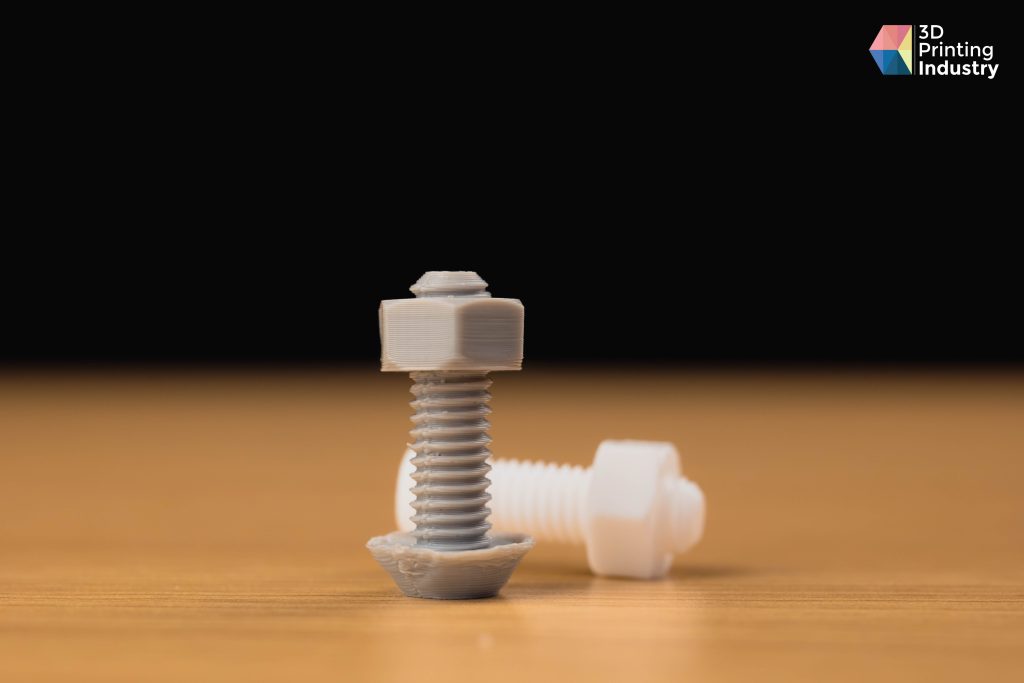

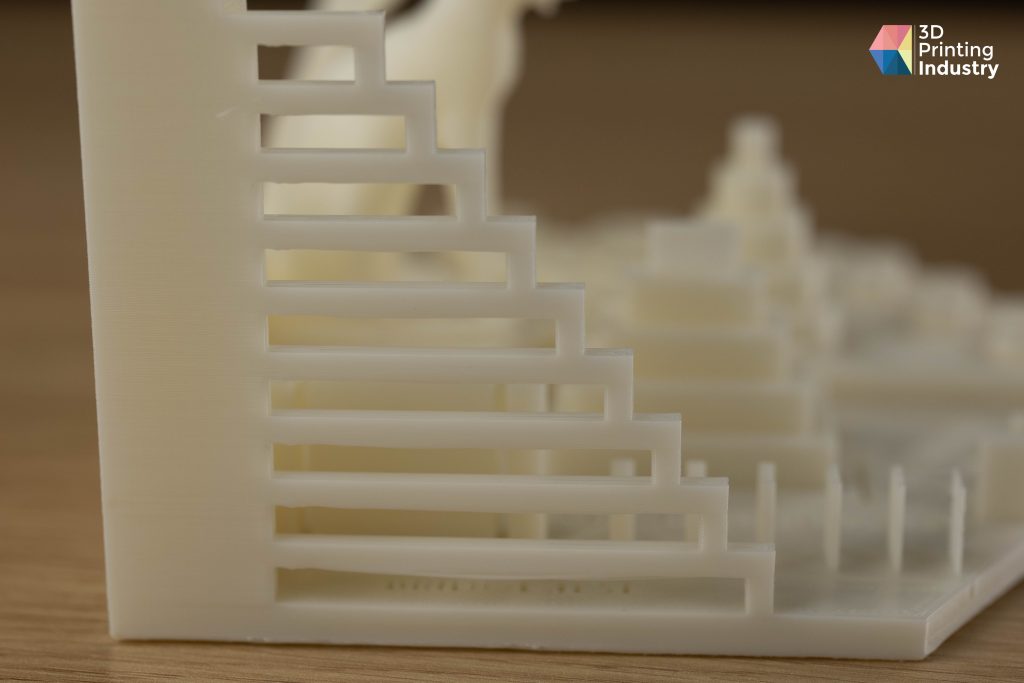

Duel Nozzle 3D Printing using IDEX

A huge draw of this printer is the IDEX (Individual Extrusion) dual extruders. All three nozzles are direct drive systems so that they can act individually from each other without interference. This grants the user various options when printing parts. Two parts using different materials can be manufactured simultaneously; this is a huge benefit for companies that need rapid prototyping as it halves production time.

This same arrangement can produce one singular part with multiple material properties or cosmetics, which is excellent for both the professional and consumer markets.

FlashForge Creator 4S 3D Printer. Dual extrusion screw measuring tool. Photo by 3D Printing Industry.

FlashForge Creator 4S Final Verdict:

The FlashForge Creator 4S 3D printer has many positive features that make it a promising competitor in the commercial market. It is, although, slightly weakened by certain design oversites. These issues impact the use of the machine, and for some users, this will be a breaking point on purchase.

However, the slicing software has been updated heavily on this printer and comes with many tools and tutorials to make the Creator 4 as straightforward as possible.

The machine itself is very well designed and is completely enclosed. This allows more material options to be considered, as some materials only print with a specific localized temperature.

The menu is well-optimized, and the UI is clean and easy to navigate. Latency is not an issue on this machine; some other machines struggle slightly.

The weaknesses of this machine have already been covered but to summarise the main issue is the extruders loading springs colliding. This issue affects extrusion at the extremes of the bed, which will severely affect your productivity if you need to print a large piece. The nozzle changing could also be more optimized as it is not very efficient compared to other multi-nozzle machine setouts.

| Build volume | 400mm x 350mm x 500mm |

| Dimensions | 840mm x 675mm x 1000mm |

| Weight | 90kg |

| Printheads | Two |

| Max bed temperature | 130°C |

| Max nozzle temperature | 360°C |

| Max chamber temperature | 65°C |

| Connectivity | Wi-Fi, USB flash drive, Ethernet |

| Nozzle Diameter | 0.4mm, 0.6mm, 0.8mm |

The featured image is Flashforge Creator 4S 3D Printer. Photo by 3D Printing Industry.