The FABtotum project was born to build an all-in-one, open source 3D printer, 3D scanner and CNC mill that could also grow into any other instrument for personal fabrication through its community. It originated on Indiegogo and it is now going back to the crowdfunding website for the its biggest and most revolutionary addition to date: integrated SLA 3D printing with photopolymers.

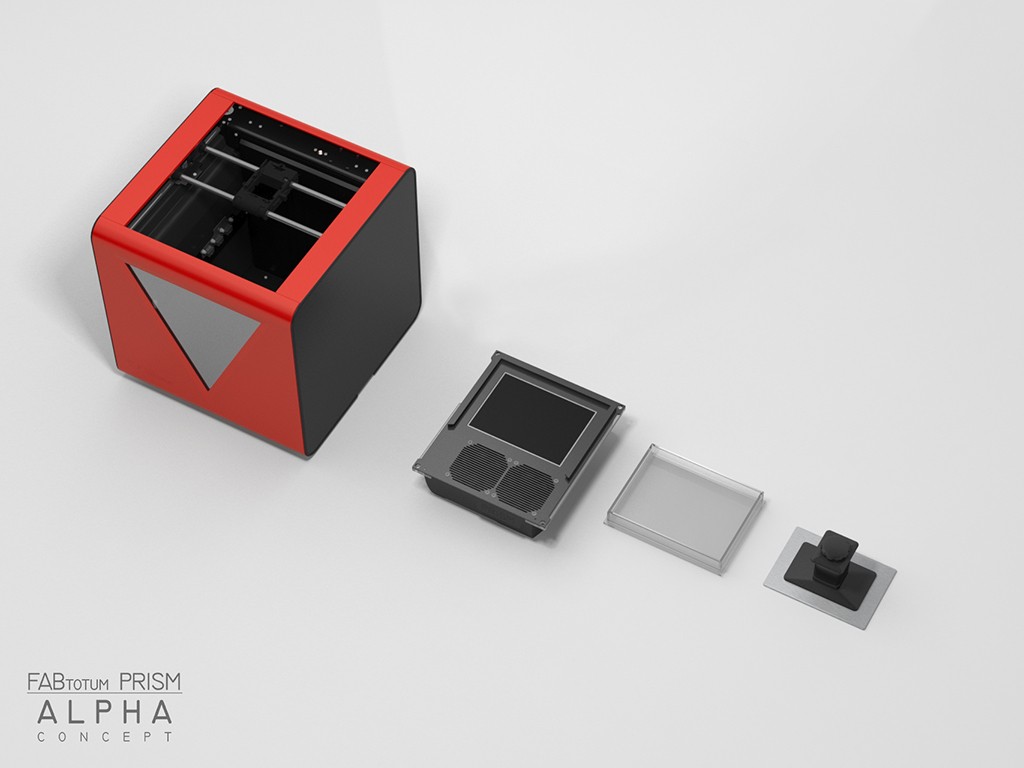

Today, the young company announced the launch of its FABtotum PRISM, a breakthrough technology that will leverage the standard 3D printing mechanics of the FABtotum 3D printer to bring high resolution, laser-based manufacturing to the desktop of all FABtotum owners at highly reduced costs.

Priced at around $1,000, the FABtotum multi-purpose fabricator is already one of the most affordable on the market. It can 3D print materials such as PLA, PETG, ABS, as well as Nylon, HIPS, and PC through FFF technology; it can use its CNC functionality to 3D mill/cut foams, brass, wood, aluminum, PCBs; and it can 3D scan models, generating point clouds via multiple 3D scanning methods with the built-in hi-res camera, touch probe, and laser scanner.

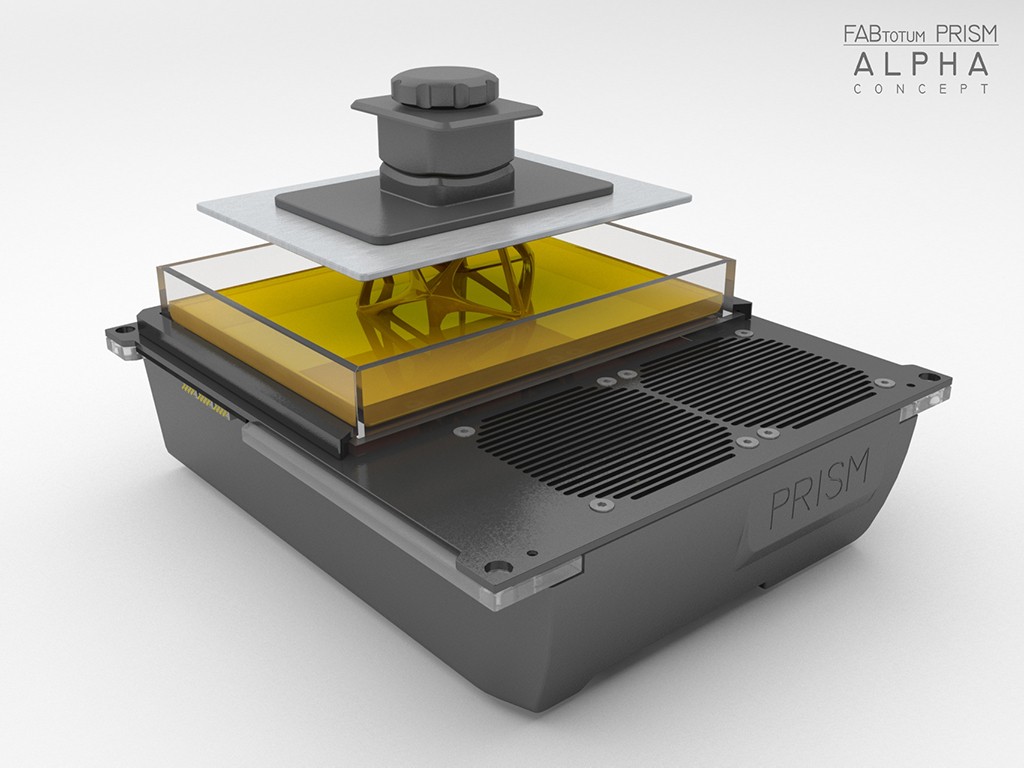

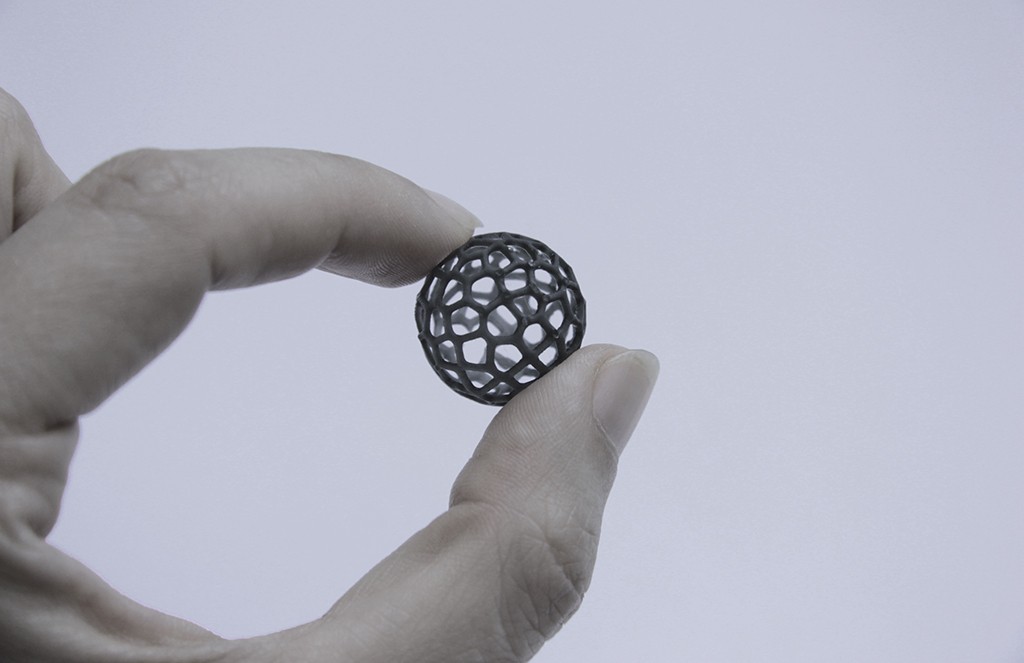

>Now, it will be able to do SLA as well. The PRISM system has already been prototyped and has yielded the first results, which look promising (as per the video below). It will be released both as an add-on and bundled with new machines. According to the FABtotum team, which is made up of young and capable engineers and architects, it will require fewer calibrations than other low cost SLA 3D printers and allow to quickly get started with this type of high resolution manufacturing.

The PRISM system has been engineered to reduce costs by focusing more power per area unit by flashing its light source only when and where needed, saving both energy and time. It can also virtually scale up to higher levels that today are still unavailable for standard DLP systems. This would mean being able to cure a single pixel (or voxel) in a much shorter time. According to the FABtotum team, since the the PRISM printing speeds are inversely proportional to the area cured, as is the case for SLS systems, it is much faster than conventional DLP systems, SLS and LED-LCD systems.

For Makers everywhere, probably the most welcome news is that FABtotum is not, in any way, shying away from its original, fully open source approach, and they are releasing all specifications for the PRISM system on Github. The company’s aim is to continue to grow together with its community of users, solving issues and constantly introducing new evolutions to the personal fabricator.

These also include other new heads for the machine, including the next version of the recently updated Hybrid Head and a Laser Head for laser cutting and more. It is all based on one very simple idea, that the 3D mechanics and movements for all these processes are the same, they just need calibration. Often times, simple ideas are the ones that work best.