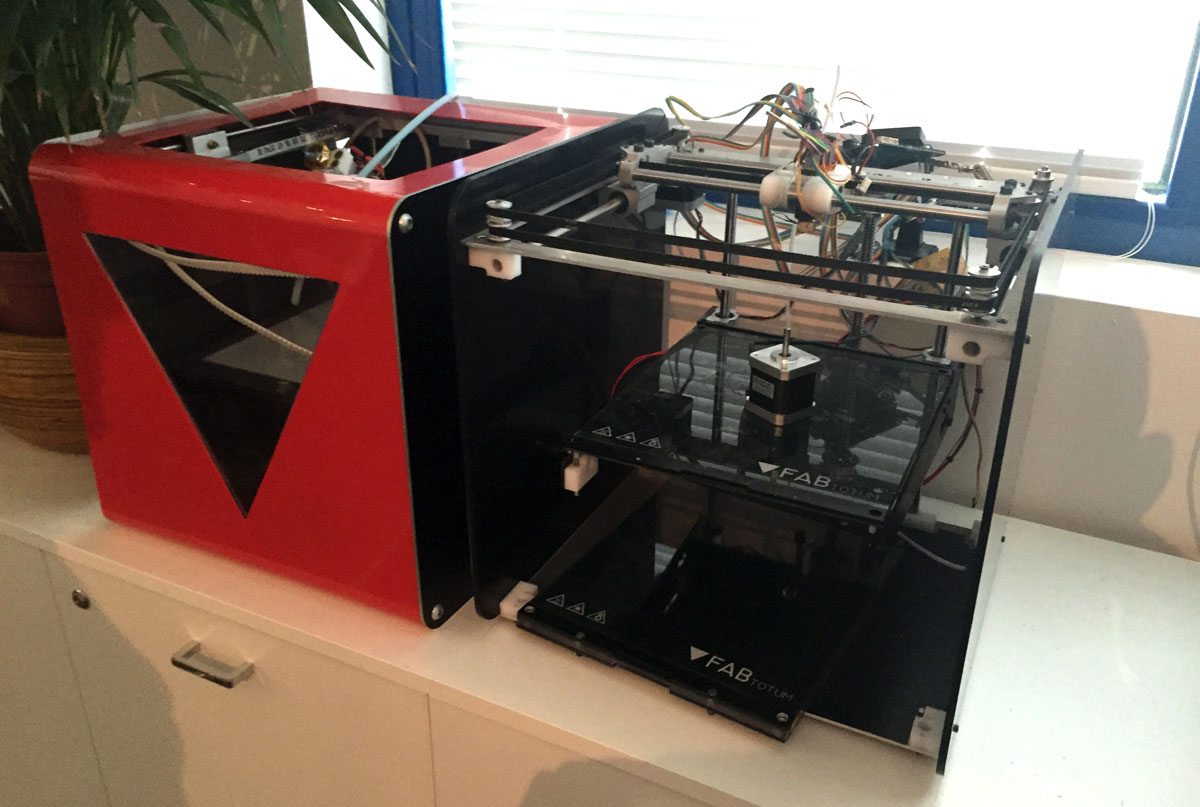

Sometimes projects that are born on crowd funding websites sound too good to be true. Earning ten times its initial $50,000 goal on Indiegogo and tons of media attention, the FABtotum just sounded like one of those. So, since I was staying in Milan for a few weeks and their factory is only about 20 miles away from my house there, I decided to go and take a look at the manufacturer of the all-in-one 3D printer, CNC router, and 3D scanner for myself.

Apparently I am not the only one. “Since we published the Indiegogo campaign, and opened up pre-orders with the machine specially priced at $1,099 (€825), a lot of people, especially here in Italy, have been coming by to make sure we were not just a scam,” says FABtotum co-founder Marco Rizzuto. Their story is well-known: FABtotum began development in 2011 and received the first funds from angel investors. The technical challenges in building a compact 3D printer that can also efficiently works as a CNC machine are considerable, but the team has done it. In fact, after seeing it up close, I can say that they have built something rather impressive.

First of all it looks really cool. Every detail has been studied accurately, form the heated plate and extruder positioning to the machine’s enclosure. The build volume to printed size ratio is 24%, better than the Ultimaker 2 and possibly the best in the industry. This percentage number, though, does not fully convey the fact that the 36cm X 36cm X 36cm 3D printer is almost entirely dedicated to the 214x236x242 mm 3D printing space. There are other details that show the great amount of research work that was put into this machine: for example, the 24-Watt power system which gets the nozzle to printing temperature in 45 seconds and the plate to temperature in just under two minutes.

So, the FABtotum team has come through on its many promises and also on the most difficult promise to keep: that of making the machine entirely open source. Marco assured me that everything about the machine and its head is fully open source: its full documentation, including drawings, is available and the reproduction of the FABtotum is allowed and encouraged under a Creative Commons license.

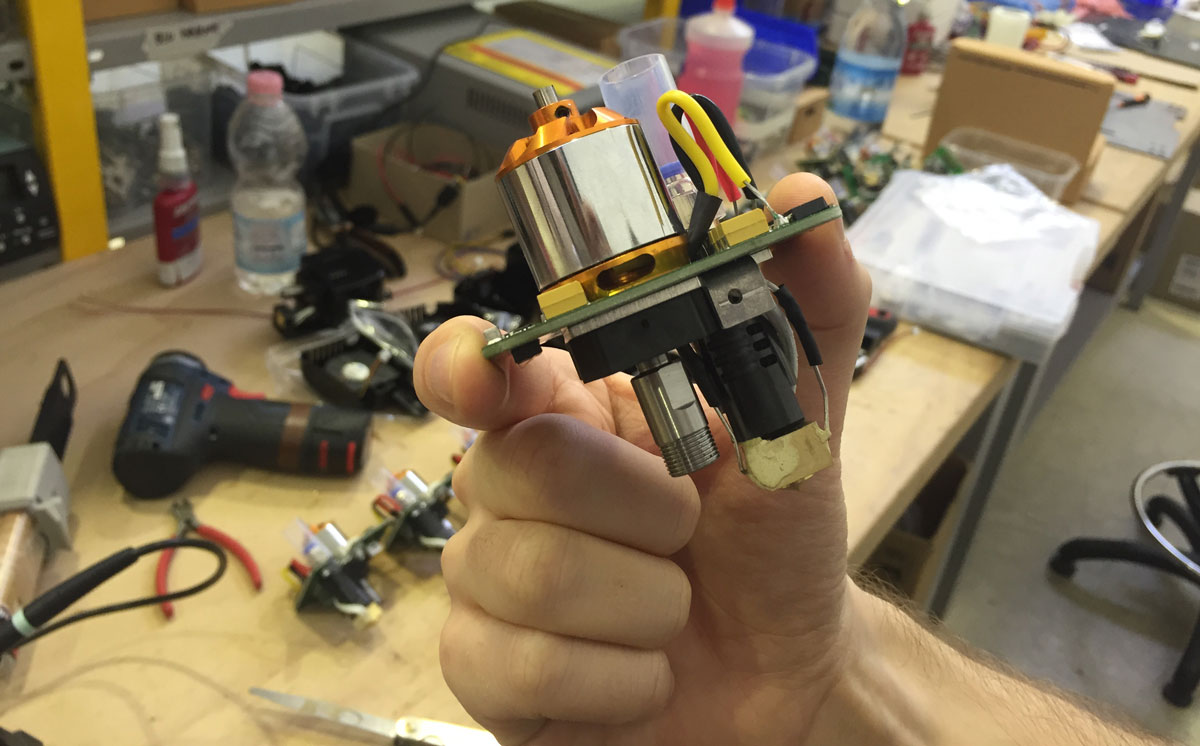

Most of the users’ contributions are and will continue to be focused on the extrusion/milling/engraving/scanning head. “We want to integrate many more possibilities in the future, like higher wattage in the milling system or added laser capabilities,” Marco says, “ and we are very happy that our community has already begun working on and has already come up with the first mods: a plotter and a measuring tool.”

The company was founded by two architects and two engineers. Getting these very different backgrounds to get along is very difficult in any project, but, when they do, amazing things can happen. Their FABtotum can have up to five possible axes to be used for alternative options and further development (including potential support for SLA technology).

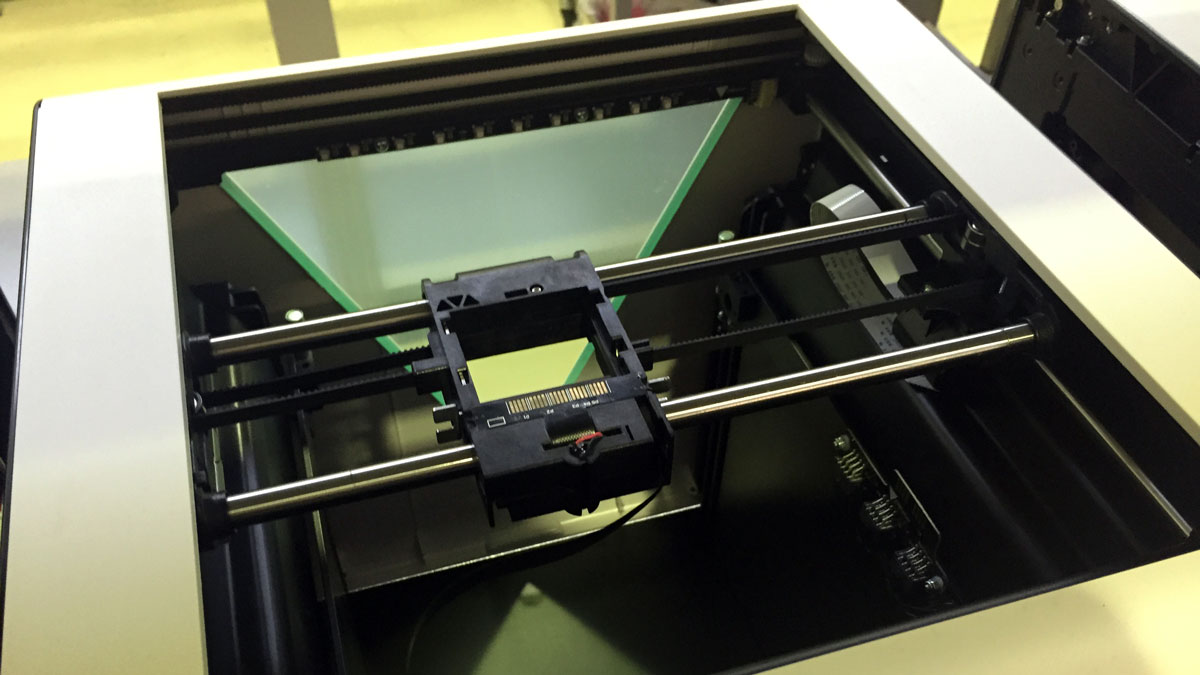

The extra axes also come in handy for the 3D laser scanning system, which also includes three different modes: rotating laser scan, sweep laser scan, and Z-Probe Digitizer in order to 3D scan even the smallest objects and to do it rapidly. The entire system can also be controlled over the web, through a cabless LAN, wireless LAN or even a remote Internet connection (with a properly configured home network). The FABtotum 15-person team also includes a software group that is constantly developing and improving the software interface.

Although Marco and all of FABtotum come across as very humble, they are extremely confident as to the quality of the product that they have created and this confidence also shines through the way that the factory is set up. Every machine is assembled in neat lines, with all stations opted for efficiency, something that took some time and a few trials to achieve. “We built this on a core XY open source architecture and also added a number of improvements. We did not save on costs to get the best parts and, so far, it looks like our efforts have been appreciated.

FABtotum has been selling its machines abroad, in particular, in as many a 63 different countries; however, the Italian market is now also starting to respond, accounting for as many as 20% of all orders. The recent media coverage by national TV channels and newspapers has been helping, after all. To learn more or to purchase your own, visit the FABtotum website.