Examining the nanotextile studies of the the Karlsruhe Institute of Technology or even the nanoscopic art of Jonty Hurwitz, it’s clear that the research surrounding nano 3D printing has only just begun. Scientists at ETH Zurich may be among the first to have explored 3D printing in the medical field. With a paper titled “Superparamagnetic Twist-Type Actuators with Shape-Independent Magnetic Properties and Surface Functionalization for Advanced Biomedical Applications” published in Advanced Functional Materials, ETH Zurich researchers have begun outlining a method for fabricating nanoprinting actuators that can drive micro-devices carrying medicines in the human body.

In the past, conventionally-created, microscopic medical devices have been difficult to control and keep stable, due to their shape. Doctoral student in the Micro and Nanosystems program and lead author, Christian Peters, explains, “Previously, these elements wobbled as they moved forward, and they were less efficient because their magnetic properties were not ideal. We have now developed a material and a fabrication technique with which we can adjust the magnetic properties independent of the object’s geometry.”

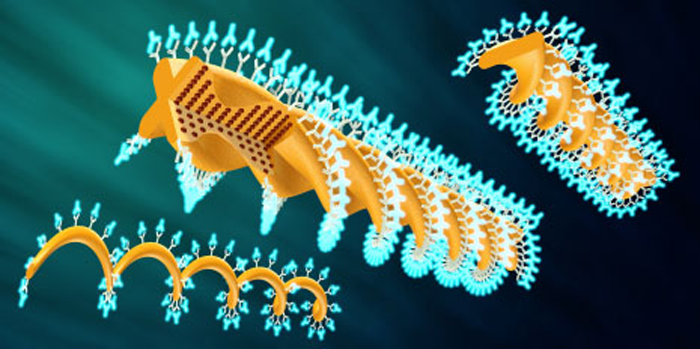

According to Nanowerk News, the technology implemented by the ETH scientists is the very same used by Hurwitz, two-photon polymerization. The biggest difference seems to be in the material used to make the micro-devices. With a light-sensitive, bio-compatible epoxy resin, the team could fabricate objects tolerable by the human body and, by incorporating magnetic nanoparticles into the material, they can control the prints with their magnetic fields. In order to determine the magnetic properties of the prints, the researchers magnetized the nanoparticles during the printing process. All of this combined resulted allowed the ETH team to 3D print microscopic, helix-shaped actuator elements that can be controlled by an external magnetic field to swim through liquids.

These 3D printed objects are 60 micrometres in length and nine micrometres in diameter and have a magnetization along their longitudinal access that gives the researchers the ability to control them with extreme precision. Moreover, the devices can swim almost four times the speed of conventional created micro-objects, without wobbling.

To further test the technology, the team 3D printed other shapes, including spirals, twisted strips, and double-twisted wires. These shapes were able to swim just as fast as their helical counterparts, but with greater surface area. Salvador Pané, a research associate on the study, said of the shape variety, “This makes the actuators more interesting for certain applications.” By coating the actuators with medicines or chemical sensor molecules, it may be possible to transport these treatments to specific areas in the body. With a larger surface area, more of these medicines can be transported. The researchers were able to demonstrate the potentiality of this process by connecting antibodies to the surface of the actuators.

What will the future hold when you can inject yourself with microbots capable of healing your body whenever you’re feeling a little weary? I’ll answer that question for you in ten years, when I have microbots making my brain smarter.