ElogioAM, the 3D pritning materials joint venture between Dutch filament startyup 3D4Makers and Perstorp, a Swedish specialty chemicals company, has received regulatory approval and is now officially opened for business.

Based in Haarlem, Netherlands, ElogioAM will provide its high-performance FFF Facilan filaments for medical applications, as well as its new dental grade filament, Facilan Ortho.

“We’ve developed this material in concert with orthotics producers, orthotics fitters and people who wear orthotics in order to develop the perfect filament for 3D printing orthotics,” said Ardy Struijk, Sales Manager at ElogioAM and Director of Sales Marketing at 3D4Makers.

“Facilan Ortho is intended to provide for more comfortable orthotics materials that are softer, better fitting, adhere better to textiles and are more comfortable than existing materials.”

The Facilan filament family

Earlier this year, Perstorp and 3D4Makers announced the beginning of a materials partnership to address the demand for more reliable FDM 3D printing quality.

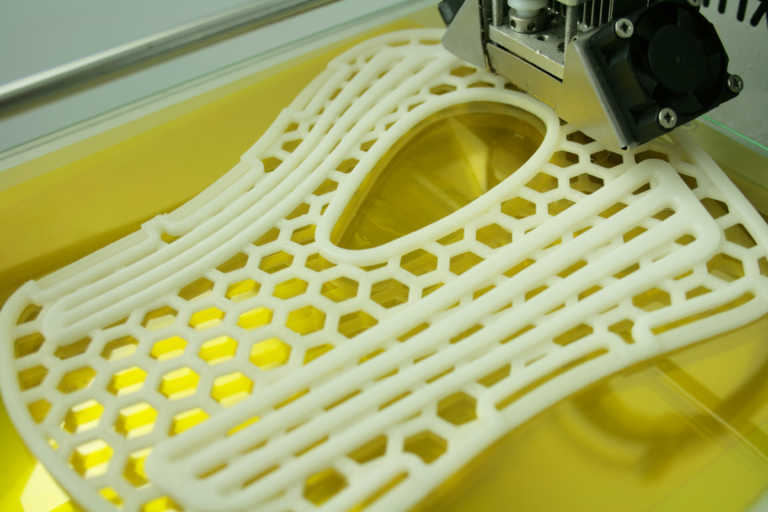

With over a century of experience in polymer chemistry, Perstorp has aided 3D4Makers in making the Facilan range of thermoplastics. The Facilan C8 filament has a higher tensile strength when compared to ABS and PLA filaments, and prints without visible layers. C8 also has the increased adhesion properties and surface quality of any FDM material.

Medical-grade 3D printer materials

Facilan Polycaprolactone (PCL) 100 is designed for advanced applications such as medical research. According to ElogioAM, Facilan PCL 100 has been used by universities to develop artificial tracheas, scaffolds for tissue engineering, and bioabsorbable implants. With a low print temperature of 120°C, this material can be reshaped after 3D printing in water with a temperature of 55 °C. This allows for form-fitting applications such as medical braces.

The newest addition to the Facilan range of filaments is the Facilan Ortho. This polyester is a semi-crystalline material that maintains a clean white finish. With a high adhesion towards textiles as well as reshaping properties, this material is designed for soft and corrective braces, and shoe soles.

In addition to its Facilan filaments, ElogioAM is currently building an Additive Manufacturing Database to increase the knowledge of new consumers adopting 3D printing technology.

Looking for the latest news in 3D printing? Subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Facilan C8 filament. Photo via 3D4Makers.