Additive manufacturing finishing systems leader DyeMansion has been chosen by the European Innovation Council (EIC) for its ‘Green Deal’ call to help the European Union (EU) fulfill its climate goals.

The Munich-based firm’s vapor polishing system, the Powerfuse S, has been awarded funding from the ‘Green Deal’ program to expand the field of application for its eco-friendly VaporFuse Surfacing technology globally.

“Being selected as one of the very first startups to work at the forefront of Europe’s mission to become the first climate-neutral continent is a great honor for us,” said Felix Ewald, CEO and co-founder fo DyeMansion. “This underlines not only the sustainability potential fo 3D printing but also the innovative ‘green’ approach that we bring to the manufacturing industry with our Powerfuse S. We take this job seriously and see sustainability as a key obligation to all our activities.”

The EIC’s ‘Green Deal’ call

Currently in a €3.3 billion pilot phase, the EIC is set to become a fully-fledged part of the EU’s new Horizon Europe program in 2021. Through its ‘Green Deal’ call, the EIC has awarded more than €307 million to 64 startups whose actions, innovations, and technologies are contributing to the EU’s Green Deal Strategy and Recovery Plan for Europe.

The EU has pledged to make Europe climate-neutral by 2050. It is believed additive manufacturing can play its part through enabling manufacturing in closer proximity to the end-user than subtractive methods, thereby shortening supply chains and reducing transport costs and pollution. The on-demand production nature of 3D printing could also significantly reduce inventories, and provide more flexibility for manufacturers.

The Powerfuse S

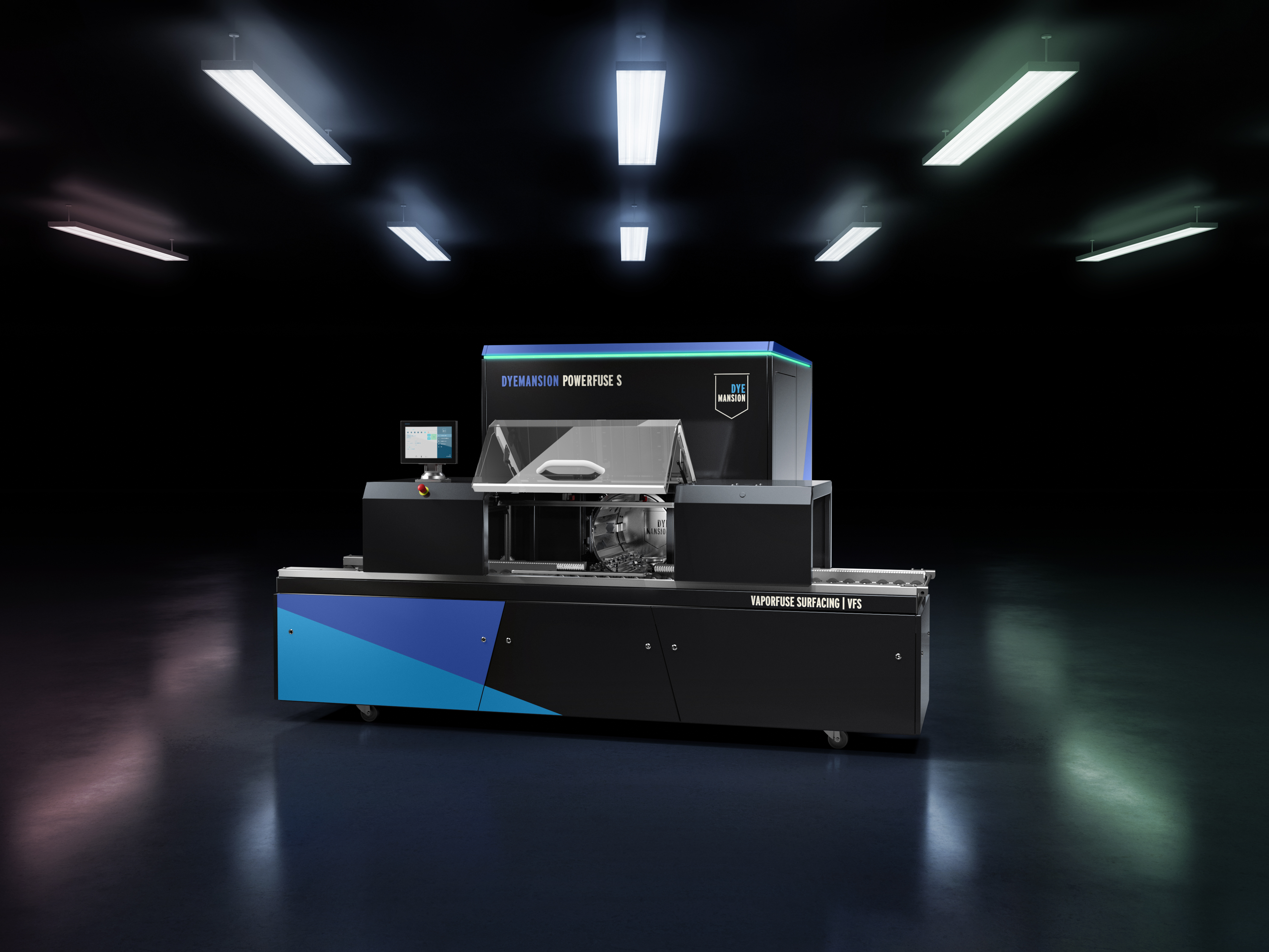

Launched at Formnext 2019, the Powerfuse S vapor polishing system delivers sealed, eco-friendly surfaces suitable for a wide range of applications. The Powerfuse S’s hardware utilizes an eco-friendly solvent approved by the EU for food packaging and cosmetic products. Operating within a fully closed loop, the system has an integrated recycling process for the solvent to avoid waste.

Equipped with a fully automatic loading concept, the Powerfuse S runs autonomously 24/7 to produce sealed 3D printed surfaces at injection molding level. DyeMansion’s VaporFuse surfacing technology then treats the parts to become pressure-tight and capable of repelling water, oil, and other liquids. According to DyeMansion, the automation element of the Powerfuse S system offers significant cost per part savings at full production capacity, leading to sustainable economic growth with little impact on the environment or its operators.

Armed with the funds from the ‘Green Deal’ program, DyeMansion intends to widen the material compatibility of the VaporFuse surfacing process and provide specific ISO certifications compliant with key sectors such as medical, and food and beverage. The company also aims to embrace the full potential of industrial Internet of Things (IoT) to enable remote monitoring and predictive maintenance of its systems and improve overall efficiency.

DyeMansion and sustainability

Founded in 2015, DyeMansion’s offering encapsulates the entire post-processing process. Its systems use a three-step ‘Print-to-Product’ method to clean, finish, and color 3D printed parts using a shot-peening technique.

The firm is part of Start Global’s Return On Society and the Environment (ROSE) project, developed with the University of St. Gallen and supported by btov Partners. ROSE encourages and supports companies to contribute a more positive societal impact.

To this end, DyeMansion created an internal sustainability committee with goals to reduce waste and receive precise GHG emissions figures to enable the company to reduce its carbon footprint in a traceable way. The committee is also charged with helping the firm contribute to social sustainability in terms of reducing the inequality between people, genders, education levels, and wealth.

“Facing climate crisis, limited resources, and global inequalities, it is obvious that companies have to rethink their way of operating,” said Lukas Erdt, Powerfuse S product manager and initiator of DyeMansion’s sustainability council. “The first step is to acknowledge the need and to commit to more sustainability, but the actual implementation is hard work. That realization made us establish an internal sustainability committee to work on these topics and appoint resources and authority to it.”

The firm recently raised $14 million in a Series B funding round, aiming to use the investment to further drive its digital manufacturing transition through increasing automation and integration across its business. Prior to this, DyeMansion unveiled 17 new vibrant post-processing colors to enable a whole new set of applications for grey 3D printed parts.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a view inside the process chamber of the DyeMansion Powerfuse S. Photo via DyeMansion.