Global bioplastics manufacturer NatureWorks has announced the launch of several technology projects to expand the capabilities of its Nebraska plant.

The projects, which are due to be completed by the end of 2021, will increase the availability of the firm’s Ingeo PLA biomaterials portfolio by 10 percent. One way in which the firm aims to achieve this is through the installation of lactide monomer purification technology at its Nebraska facility.

“The market continues to rapidly evolve due to the Covid-19 pandemic as well as the undiminished demand for sustainable, bio-based alternatives to petrochemical-based plastics,” said Rich Altice, president and CEO of NatureWorks. “For NatureWorks to satisfy this unprecedented demand, this purification technology is one of many additional capital improvements we are actively working on at our facility in Blair.”

The expanded availability aims to drive growth in markets such as 3D printing which welcome high-performance sustainable, low-carbon materials.

NatureWorks’ Ingeo biomaterials

Ingeo is the official brand name for the PLA produced by NatureWorks. Ingeo polylactic acid, the foundation of the biomaterials, is made using annually renewable plants, such as corn, to transform greenhouse gases into long-chain sugar molecules. From here, the dextrose derived from the plant sugar molecules is fermented before being turned into lactide. The Lactide monomers are then bonded to form an Ingeo polylactic acid polymer.

NatureWorks’ has produced a series of Ingeo grades designed specifically for PLA filament for the 3D printing market. The firm has also created its own in-house print lab, enabling the quick testing of new Ingeo formulations and collaboration with 3D printer and filament producers. In 2015, NatureWorks announced an initiative to support the growth of the 3D printing sector, offering a new Ingeo3D850 polymer to provide good processability in filament production, consistency, and quality.

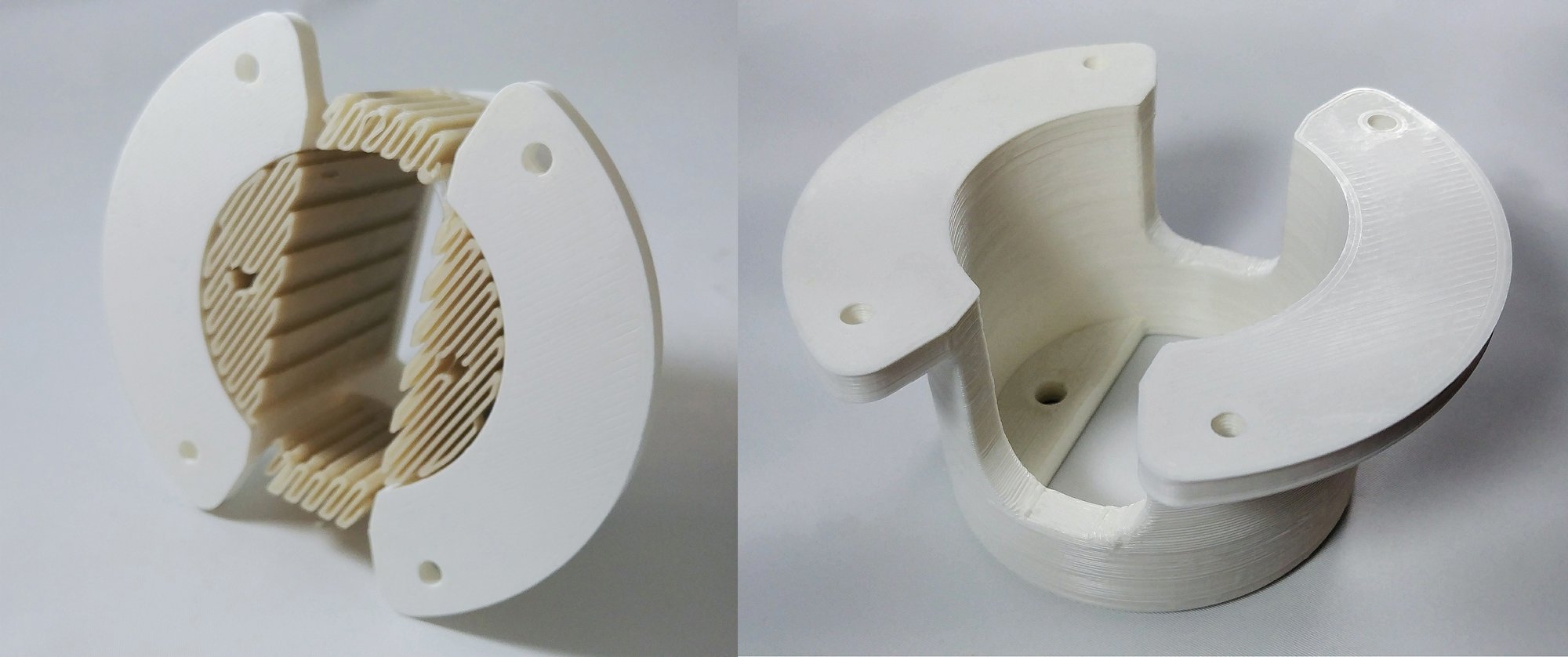

Most recently, the firm introduced Ingeo 3D450, a break-away PLA material for use in dual extrusion 3D printers. The biomaterial was designed to offer a high finish quality while reducing post-processing time.

NatureWorks’ Ingeo is used by the likes of U.S.-based filament manufacturer 3D-Fuel, which maintains its environmentally friendly footprint by using the biomaterials for the majority of its products.

Commitment to sustainability

Last year, NatureWorks announced that by 2020 100 percent of the agricultural feedstock used for Ingeo biomaterials at its Nebraska plant would be certified ‘environmentally and socially sustainable’ by the International Sustainability and Carbon Certification System (ISCC). The firm also pledged that all its new feedstocks for additional manufacturing capacity will be certified ‘sustainably and responsibly managed’ via an independent third-party by 2025.

In 2012, NatureWorks was the first biopolymer manufacturer to be verified to the ISCC PLUS standard. Presently, more than 60 percent of the company’s agricultural feedstock is verified.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the NatureWorks logo.