Being the leading global producer of PLA, Minnesota based NatureWorks is very serious about 3D printing. So serious, in fact, that it recently announced a new initiative to support the growth of the additive manufacturing market, beginning with offering the new Ingeo3D850 polymer, developed specifically to provide a good overall balance of processability in filament production, filament consistency, and print quality.

Ingeo is the official brand name for the PLA produced by NatureWorks, as the company offers more than 20 different Ingeo grades, with numerous specialized formulations, and more than a decade of world-scale production experience. In early 2014 NatureWorks – which is jointly owned by Thailand based PTT Global Chemical, and by Cargill, announced that it had reached 1 billion pound of PLA sold globally and, while that took about 10 years since the material’s entrance into the global market, the company’s CEO, Marc Verbruggen, said he expected to double that much sooner.

While most PLA demand is not related to 3D printing (the material is used for recyclable plastic bags and a wide selection of other products), there is little doubt that its versatility and ease of use as a 3D printing filament material makes this area strategic for the company.

“3D printing has the rapid pace of innovation, development, and change that is normal to a new and still nascent market,” said Dan Sawyer, Global Leader, New Business Segment, NatureWorks. “Many new suppliers are entering the PLA filament market, while a breadth of experienced suppliers large and small are formulating and compounding to provide additional filament properties and options. That’s the sort of innovation that NatureWorks is aggressively moving to support and amplify with our new broad-based initiative.”

The company’s move to support the 3D market includes the introduction of an entirely new series of Ingeo grades designed specifically for PLA filament for the 3D printing market (beginning with the Ingeo 3D850) a full suite of technical support services for the additive manufacturing industry’s leading 3D printer and filament producers (most of whom can be viewed in NatureWorks 3D Printing Suppliers Guide); and the creation of an in-house print lab, enabling the company to rapidly test new Ingeo formulations and further collaborate with 3D printer and filament producers.

“What we learned from our market engagement,” said Sawyer, “is that a large segment of the market prefers to print with PLA and would like to replace petroleum-based ABS if PLA can rival the other material’s heat resistance and the toughness of finished parts.”

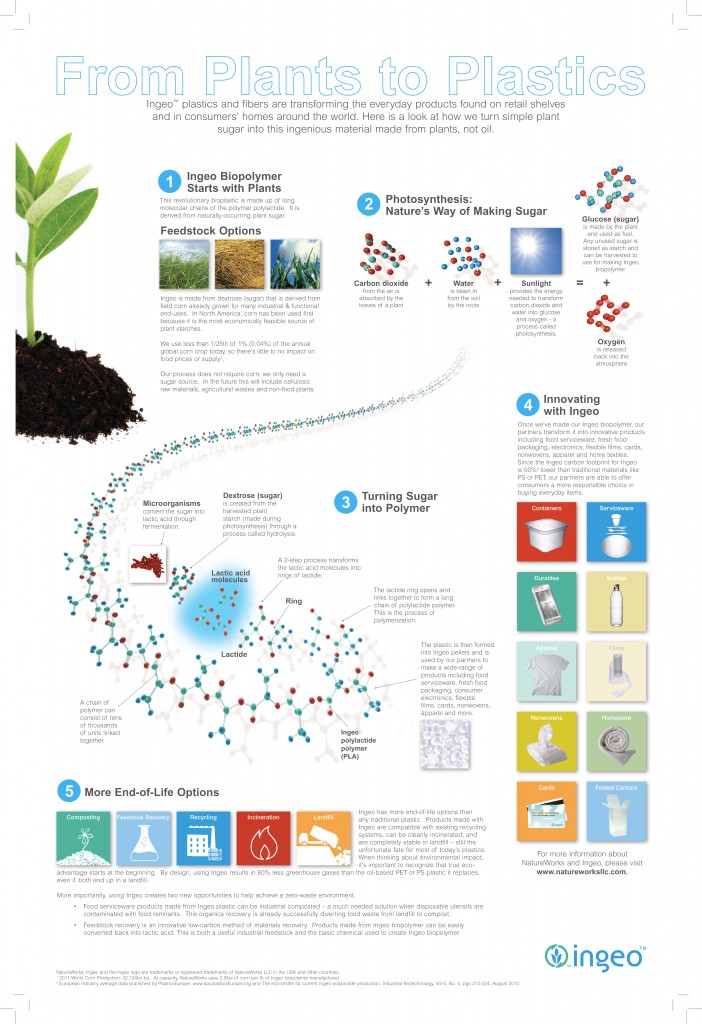

Using plastic made from natural elements, such as corn, starch, sugar cane and many other local crops makes perfects sense as it produces plastic using carbon dioxide which is already present in the atmosphere (inside the plants) instead of digging out more carbon dioxide from inside the Earth (as per oil based plastics) thus contributing to global warming. To further speed up the process of PLA adoption (petroleum based polystyrene is sold in the order of 7-8 billion pounds a year), NatureWorks is actively working to produce new higher heat and toughness Ingeo formulations inside its newly established in-house print lab, with market introduction targeted for later in the year.

While PLA is not “perfect” either (some criticize its use of corn, thus affecting its prices for food production) it is by far the most biocompatible, biodegradable and sustainable plastic resin we have and it is no coincidence that it goes hand in hand with distributed desktop 3D printing and its evolution. With the introduction of superior mechanical properties there will be no stopping it from becoming the number one plastic in the world.