German automated post-processing provider DyeMansion is set to launch new 3D printing post processing equipment at Formnext 2019.

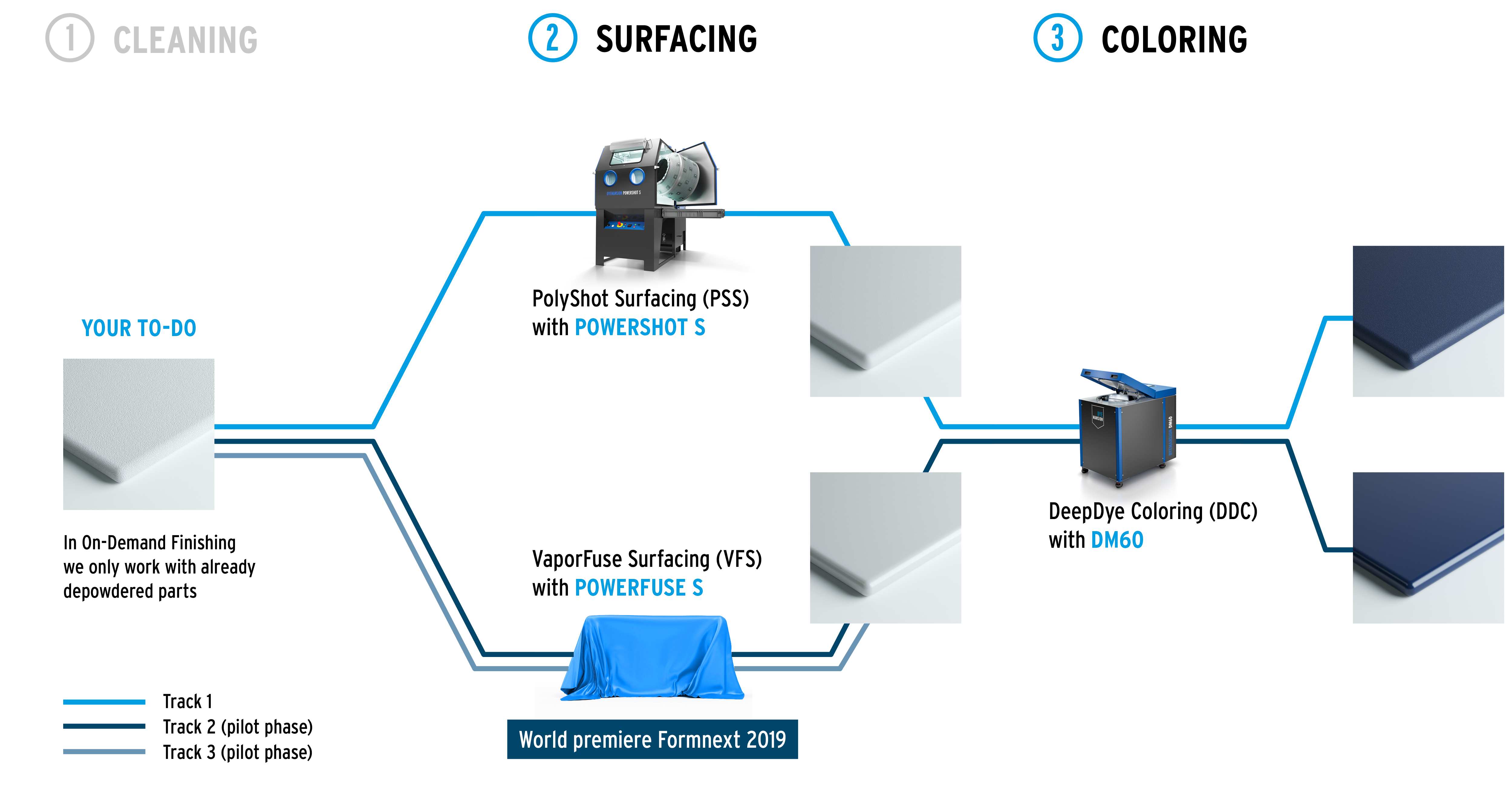

Having completed beta testing of its VaporFuse Surfacing (VFS) technology within its Print-to-Product workflow, the company will be presenting Powerfuse S, the hardware for this process, at the show next month.

A chemical-based process, VFS technology smooths and glosses polymer-based parts. It was released in 2018 as “the first clean vapor technology for 3D printed parts” in its beta-phase for materials such as PA12 and TPU (SLS) and PA12 (MJF).

Rivaling injection molded parts

VFS is a closed, automated process, capable of making 3D printed parts water repellent and easy to clean, common properties of injection molded parts. “During the process, the surface is dissolved by condensed vapor,” explained DyeMansion’s R&D Chemist Dr. Alena Folger on the introduction of the technology, “Thus, the polymer chains have a sufficiently high mobility and rearrange at the surface.

“The overall surface area and the surface energy is reduced. Concurrently, the part is smoothed. Upon removing the solvent, the polymer hardens again.”

The process is the second surfacing option from DyeMansion, and acts as an alternative to PolyShot Surfacing (PSS), a mechanical matte-finishing process, that also enables the addition of vibrant colors across the RAL spectrum.

Print-to-Product workflow

The full DyeMansion Print-to-Product workflow provides 3D printed part cleaning, surfacing and coloring for laser sintering (LS) and HP Multi Jet Fusion (MJF) processes. The Powershot C, delivers automated part cleaning, whereas the Powershot S uses PSS technology. According to the company, the newly developed VFS Powerfuse S system is suitable for both hard and flexible polymer parts.

Visitors to Formnext 2019 can see the Powerfuse S and DyeMansion’s other post processing technologies in Hall 11.1, stand D61 from November 19th to the 22nd.

To learn more about how 3D printing, subscribe to our 3D printing newsletter and join us on social media: Facebook and Twitter.

For job opportunities in manufacturing, visit our 3D Printing Jobs page.

Featured image shows a 3D printed post-processed part. Photo via DyeMansion.