Researchers from the Delft University of Technology have designed and printed a porous titanium bone implant with antibacterial properties.

Leveraging a novel biofunctionalization method called plasma electrolytic oxidation, the team was able to load the implant with strontium and silver nanoparticles, eradicating the notoriously resistant Staphylococcus aureus bacteria within 24 hours. The researchers believe the synergistic antibacterial behavior they discovered between the strontium and silver could give rise to a new type of implant – one that outlives patients with minimal maintenance.

Designing orthopedic implants

Bone implants are one of the most popular in the medical device industry and can be found in millions of individuals around the world. Like any other functional device, however, they too have a limited working lifespan. Towards the end of the service life, loosening begins to occur – marked by a deterioration of the patient’s mobility and onset of aches and pains.

The ultimate goal of a bone implant is to ward off loosening long enough that the patient goes before the implant does (all while serving its purpose, of course). To do this, the implant must replace the native bone tissue, whereby the surrounding bone grows over the surface of the implant and fuses to it in a process called osteogenesis. For years, researchers have tried a number of approaches, including the synthesis of new biomaterials, surface biofunctionalization, and even local active agent delivery, but it remains a topic of ongoing trial and error.

Strontium and silver

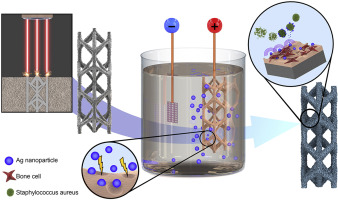

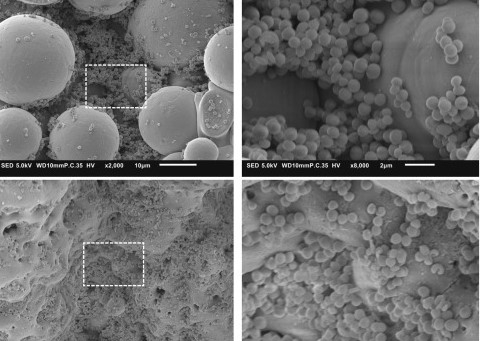

With the ultimate goal in mind and the funding of the engineering department behind them, the team printed a sample Ti-6Al-4V implant using SLM technology. Then, plasma electrolytic oxidation – an electrochemical surface treatment process for generating oxide coatings – was used to biofunctionalize the surface of the implant with strontium and silver. Here, the strontium served to encourage bone growth while the silver provided the antibacterial properties. The team found that both active agents were continually released for up to 28 days, and the Staphylococcus aureus strain was virtually non-existent after 24 hours of surface contact.

Interestingly, an extraordinarily synergistic antibacterial relationship was discovered between the strontium and silver. While in the presence of strontium, 4x – 32x lower concentrations of silver ions were required to kill off the whole bacterial culture, despite the strontium itself not having any bactericidal properties. The researchers see their work as an advanced prototype of future orthopedic biomaterials and hope to see their discovery made use of in a clinical setting.

Further details of the study can be found in the paper titled ‘Functionality-packed additively manufactured porous titanium implants’. It is co-authored by Ingmar A.J. van Hengel, Francisca S.A. Gelderman, Stefanos Athanasiadis, Michelle Minneboo, Harrie Weinans, Ad C. Fluit, Bram C.J. van der Eerden, Lidy E. Fratila-Apachitei, Iulian Apachitei, and Amir A. Zadpoor.

The development of antimicrobial materials is rampant in medical device research. Recently, researchers from Tsinghua University, Beijing, 3D printed a personalized cervix tissue implant to counteract human papillomavirus (HPV). Working on the same premise as the Delft study, the porous structure of the polyurethane implant was loaded with an anti-HPV protein that was quantitatively released to inhibit HPV growth.

Elsewhere, materials scientists have developed a starch-infused polycaprolactone (PCL)-based composite filament for use with low-temperature FDM machines. The filament was then further functionalized via the addition of bioactive ingredients, giving it antibacterial properties that work in a wide temperature range.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

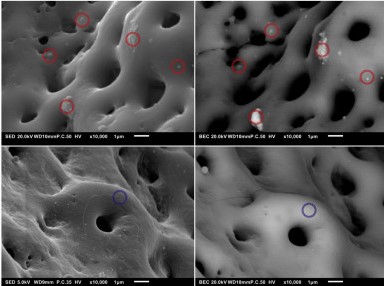

Featured image shows SEM imaging of the bacterial clusters on the implant. Image via Delft University of Technology.