Due Pi Greco, an Italian product development service provider, has leveraged FDM 3D printing technology from Stratasys to expand its use of additive manufacturing from prototyping to production.

The company has implemented a total of five Stratasys FDM 3D printers alongside Nylon 12CF, ULTEM 9085 resin, ST-130 and ASA materials into its product development process. As such, Due Pi Greco has been able to create new production applications for different industries, replacing traditional, more expensive methods with additive manufacturing.

“Stratasys’ diverse range of production materials allow us to develop some innovative applications for our customers. For example, we recently designed and 3D printed a boiler for Zoppas, a global supplier of heating systems for domestic and industrial use. This was made possible with ULTEM 1010 resin as it’s the only polymer that can perform at high temperatures up to 216 °C,” explains Diego Pagnan, Founder and Owner at Due Pi Greco.

“Without the advanced properties of these materials, we simply wouldn’t be able to exploit the great efficiencies of additive manufacturing for these types of demanding production applications.”

A fast and cheap alternative to metal CNC machining

Due Pi Greco has been providing product development services specializing in the design, engineering, prototyping and manufacture of functional parts and components since 2010. The company has long since implemented 3D printing within its production processes, however mainly for prototyping components and optimizing product design. Using Stratasys 3D printers has allowed Due Pi Greco to explore additive manufacturing for end-part production: “When we started our business, we predominantly operated as a 3D printing service provider for prototyping requirements,” adds Pagnan. “However, using Stratasys 3D printers throughout all our development work has enabled us to better understand the significant potential of additive manufacturing for production.”

Having already been using four Stratasys FDM 3D printers, the company recently purchased a Fortus 380mc Carbon Fiber Edition (CFE) from Stratasys’ Italian reseller, Energy Group. Due Pi Greco opted to purchase the new system in order to use Stratasys’ FDM Nylon 12CF material, a 3D printed composite comprising 35 percent chopped carbon fiber. With this material, the company has been able to meet high part performance demands from new customers, thus increasing its number of clients: “Fortus 3D printers have always been reliable workhorses for us, but we decided to invest in the Carbon Fiber Edition as we found it the best alternative to CNC machining expensive metal parts,” says Pagnan. “Using FDM Nylon 12CF, we’re able to 3D print parts that perform similar to those produced using CNC processes.”

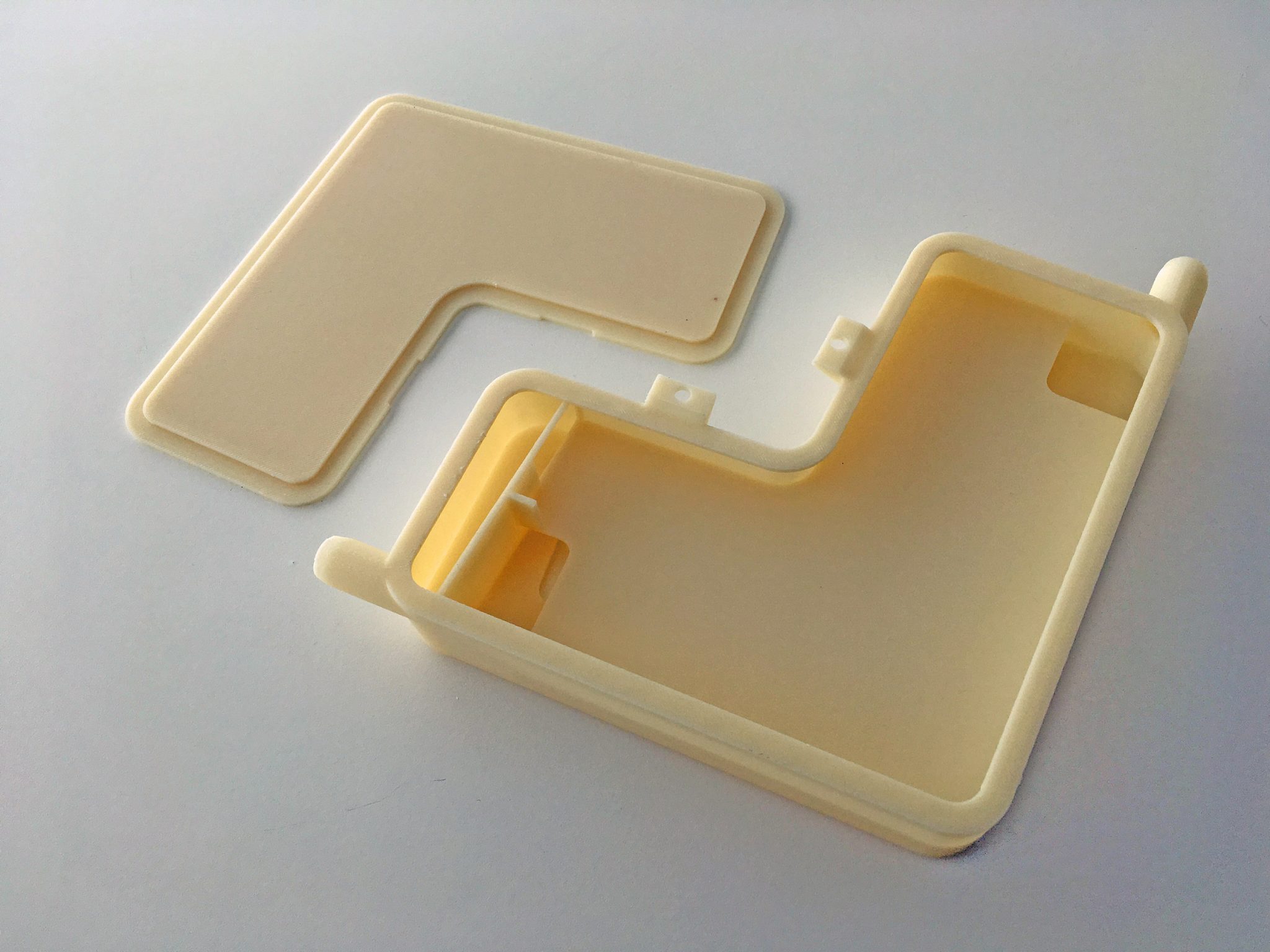

For example, Due Pi Greco recently collaborated with the University of Padua to 3D print an airbox for the engine of a single-seat race car set to race at Formula SAE. Leveraging FDM Nylon 12CF on the Fortus 380mc CFE, the company was able to improve upon the lead times and costs of conventional carbon fiber production. Additionally, Due Pi Greco also worked with an unnamed Italian cycling brand to optimize the design and production of a bicycle seat using the Fortus 380mc CFE 3D printer. According to Pagnan, the customer reported that the result went beyond expectations in terms of surface finish and resistance.

Stratasys Carbon Fiber 3D printing in automotive

Stratasys’ Fortus 380mc CFE originally began shipping to customers in 2018. The 3D printer was released in order to address the growing demand of carbon-fiber composite applications. The system is dedicated to Nylon 12CF, a material designed for functional prototypes and end-use components in the automotive and aerospace industries. Since the release of the 3D printer and material, they have both seen various applications across a number of industries, particularly in automotive.

At RAPID + TCT 2019, Stratasys revealed that Arrow Schmidt Peterson Motorsports had been using Nylon 12CF to create functional prototypes, product components and rugged tooling for its racing vehicles. British supercar manufacturer Briggs Automotive Company (BAC) has also used Nylon 12CF to produce a prototype iteration of an airbox component for its Mono R supercar. Finally, the U.S. sports car racing team Team Penske used the Fortus 380mc CFE to produce prototypes and production parts for vehicle testing.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed airbox on the University of Padua student race car. Photo via Stratasys.