US-based metal 3D printer manufacturer Mantle has expanded the reach of its 3D printing technology, including the P-200 metal 3D printer, with three new customers.

These new customers include Spectrum Plastics Group, a DuPont business; Heyco Products, a Penn Engineering company; and General Pattern.

Mantle has also shared that its metal 3D printing technology is significantly reducing the time and costs needed to produce high-quality tools, molds and dies.

The firm’s 3D printing products have allowed existing customer Westminster Tool to eliminate 110 hours of labor and machining time, cutting steel prototype lead times by 50%. Westminster Tool has subsequently accelerated tooling product development for its medical device OEM customers.

These announcements highlight the wide array of industries and applications utilizing Mantle 3D printers. Use-cases range from medical device toolmaking, to addressing critical labor shortages in the toolmaking sector.

“Mantle’s technology remains a game-changer in the toolmaking industry, consistently driving reductions in lead times and costs while addressing labor shortages,” stated Ted Sorom, CEO and Co-founder of Mantle.

“The latest deployments, with Spectrum Plastics Group, Heyco, and General Pattern, coupled with the ongoing success of our existing customer, Westminster Tool, underscore the growing adoption and effectiveness of our technology.”

Mantle halves prototyping lead times

Westminster Tool is an injection mold manufacturer specializing in class 101 medical device tooling. Having acquired its first Mantle 3D printer back in June 2022, the company has actively identified new applications and tested the flexibility of Mantle technology.

Recently, Westminster Tool partnered with a medical device manufacturer to 3D print a complex set of mold inserts. These inserts were designed to allow the medical OEM to quickly mold production-representative plastic parts for material validation.

Mantle 3D printers reportedly enabled Westminster Tool to produce the steel mold inserts in the space of just four weeks. The company claims that the components would have taken eight weeks to produce with traditional manufacturing techniques, allowing its customer to accelerate its product development process.

Once 3D printed, the tools required minimal finishing, reducing labor and machining time by over 110 hours. The H13 steel tool inserts were complex, including over 40 swipe-by shutoff conditions and contoured parting lines which would otherwise be incredibly time-consuming to manufacture.

New customers leverage Mantle technology

Spectrum Plastics Group, another medical contract manufacturer, has recently implemented Mantle’s metal 3D printing technology into its facilities. Heyco Products, a company specializing in wire protection and termination for a range of industries, also recently acquired Mantle 3D printing technology.

High-quality tooling is said to be critical to Heyco’s operations, with the company having manufactured thousands of complex plastic and metal components.

“At Heyco, we pride ourselves on taking products from design through to volume production, which includes in-house prototype and production tooling,” commented Heyco Products’ Vice President of Operations Danny Anthony. “Mantle allows us to increase our toolmaking capacity and project speed by automating a portion of our toolmaking process, helping to maximize our skilled resources.”

Mantle has also noted that its technology helps to alleviate labor scarcity challenges within the toolmaking industry. General Pattern, an injection molder offering in-house tooling services, has introduced Mantles P-200 3D printer to automate its toolmaking processes and increase capacity.

General Pattern anticipates this investment will heighten production efficiency, decrease reliance on specialized labor, and improve customer service through faster and more efficient operations.

“Introducing Mantle into our operations has elevated our approach to toolmaking. With the simple press of a button, we can now effortlessly create tools, which completely changes our ability to tackle labor challenges and enhances our capacity to better serve our customers,” stated General Pattern CEO Denny Reiland.

“Recently with a slide for a transportation trim component, for example, we skipped the finishing process entirely. Instead, we printed it, assembled it into the mold, and immediately began molding parts,” added Reiland. This reportedly saved 40 hours of traditional toolmaking time, allowing the team to focus on other key projects.

Additive manufacturing optimizes tooling production

Within the context of lead time challenges and labor shortages, additive manufacturing is playing a growing role in tooling production.

In a survey on 2024 3D printing trends, 3DWithUs founder Max Funker noted that as 3D printing continues to grow, it will become a go-to option for manufacturing tooling, as well as in prototyping and small batch production.

French metal 3D printing specialist AddUp has previously launched its AISI 420 steel 3D printing material optimized for the production of complex and efficient molds with reduced post-processing needs. The material is compatible with the company’s FormUp 350 powder bed fusion (PBF) 3D printers, and is designed for the creation of molds for injection molding due to its high levels of mechanical strength and corrosion resistance.

Following its development, German tooling manufacturer Aachener Werkzeubau Akademie (WBA) deployed the AISI 420 steel alloy at one of its facilities. Using the material, WBA successfully 3D printed molds with porosity rates of less than 0.05%, guaranteeing durability under high stress.

Elsewhere, binder jet 3D printer OEM ExOne offers its own portfolio of 3D printed tooling products. The X1 Tooling range was said to be the world’s largest offering of industrial-grade 3D printed tooling upon its launch in 2021, and includes tooling for plastic injection molding, forming, composite layups, and metal castings.

ExOne launched its 3D printed tooling in an effort to secure supply chains, reducing lead times and cutting costs in the process.

“As the COVID pandemic has continued disrupting supply chains, we’ve had more and more manufacturers ask us: ‘Can you 3D print tooling?’ Today, we’d like the market to know that the answer is yes,” stated John Hartner, CEO of ExOne, following the 2021 launch of X1 Tooling.

“We can help de-risk your supply chains and make them more sustainable, with less shipping and other forms of waste,” added Hartner. “Our new tooling portfolio is a grand slam of fast and affordable new tooling options for manufacturers.”

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

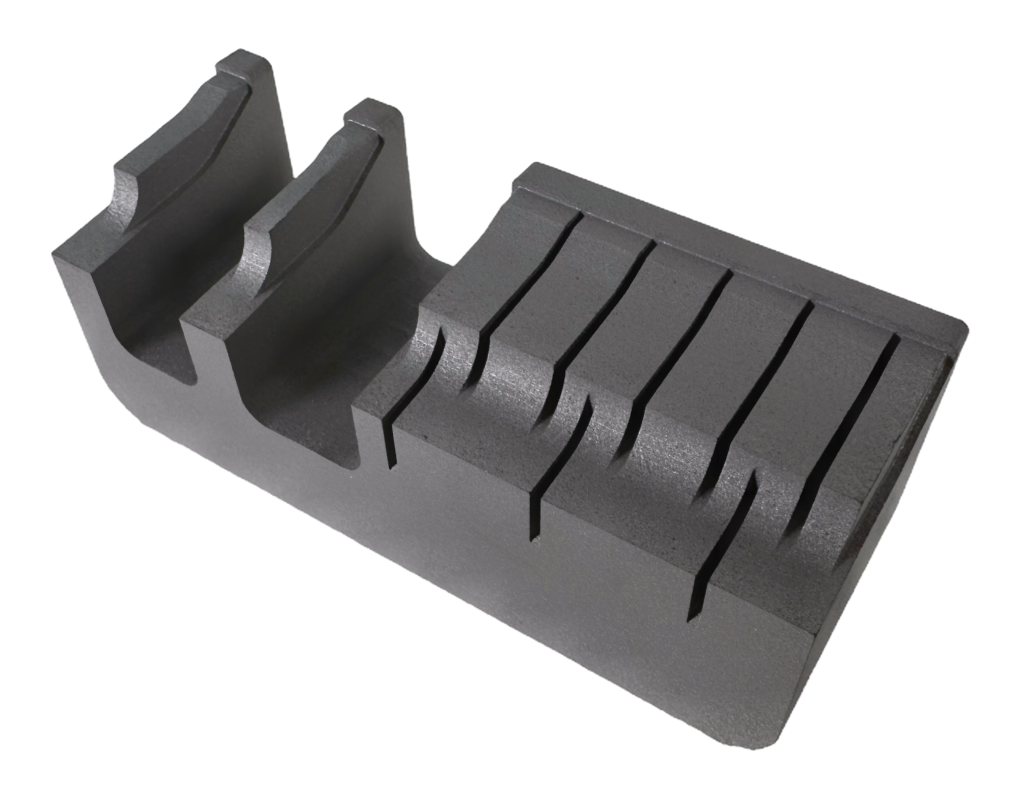

Featured image shows Mantle shipment to Spectrum Plastics. Photo via Mantle.