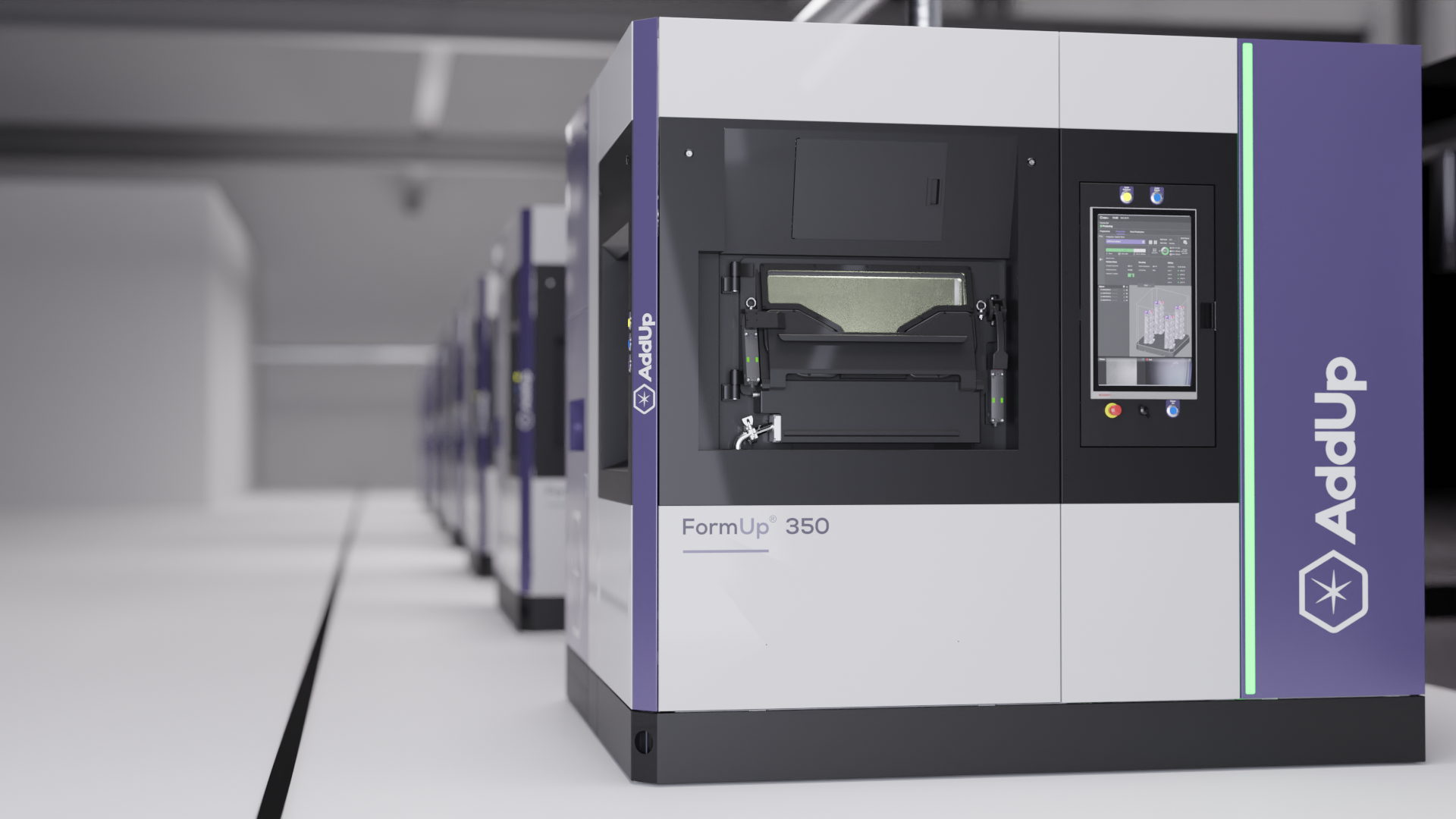

French industrial 3D printer provider AddUp has launched its latest metal 3D printer, the FormUp 350.

The result of two years of research and testing, the laser powder bed fusion (LPBF) based machine is designed to address industrial challenges of safety, productivity, quality, and machine obsolescence.

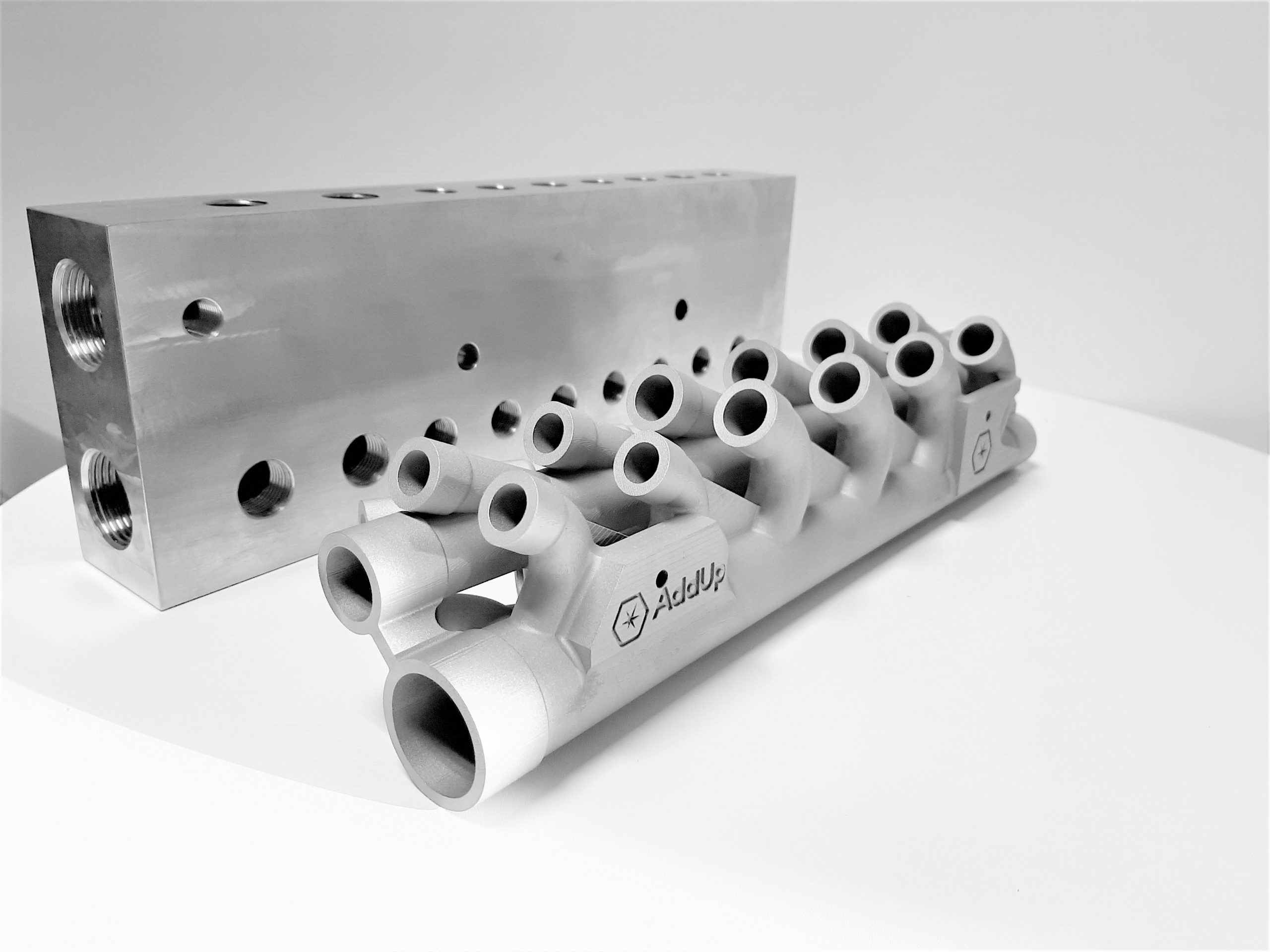

Leveraging a modular and scalable architecture, the FormUp 350 enables manufacturers to deliver reproducible series of industrial parts at higher levels of productivity and performance than previously achievable.

Advancing LPBF 3D printing

AddUp is the additive manufacturing venture of French industrial engineering group Fives and Michelin, established in 2016. In addition to LPBF, the firm utilizes Directed Energy Deposition (DED) and Electron Beam Melting (EBM) 3D printing systems to produce industrial parts.

The company currently operates a fleet of nearly 40 machines at its Cébazat, Strasbourg and Salon de Provence sites in France.

In January 2020, AddUp entered into a $2.7 million cooperative research and development agreement (CRADA) with the Oak Ridge National Laboratory (ORNL) to advance LPBF processes for novel metal molds used in tooling.

The firm has also previously been involved in the 3D printing of titanium components for the aerospace sector, producing 3D printed tire molds for the automotive industry, and 3D printing artificial hearts.

The FormUp 350 3D printer

The FormUp 350 has been engineered to overcome four main challenges to industrial 3D printing, namely safety, productivity, quality, and obsolescence.

Starting with safety, the FormUp 350 can be used with all types of metal powders, including those that are reactive. The machine features an autonomous powder module developed exclusively with the AZO Company which facilitates the closed-circuit automatic storage, conveying, recovery, and sieving of powders during the manufacturing process.

Meanwhile, an automatic passivation filter system minimizes exposure to fumes and smelting residues and ensures safe waste disposal. Calcium carbonate is also added to the soot and powders recovered during filtration to remove the risk of flammability and ensure safe processing.

In terms of productivity, the FormUp 350 can print using four 500W lasers simultaneously with each covering the entire surface of the build platform. A bidirectional coating system increases the speed of powder spreading by 40 percent, while a cooling system for the machine’s Z-zxis lowers the platform temperature at the end of production to enable parts to be unloaded faster.

Other features to maximize the machine’s uptime include a long-life fume treatment module, the use of Cross Jet technology to limit soiling of the laser protection glass during manufacturing, and the ability to calculate trajectories up to 1,000 times faster than real production, with 1.27 million generated per second.

AddUp’s FormUp 350 has been engineered to meet the stringent quality requirements of its customers which hail from a range of sectors including aeronautics, space, motorsports, defense and medical.

Specific “manufacturing recipes” can be developed for each individual application in order to strike the optimum balance between productivity and quality for each part. The machine’s lasers each boast a spot center geometric precision of 35 µm, and are equipped with a 3-axis optical chain that guarantees both positioning accuracy and laser beam quality.

According to AddUp, the FormUp 350 is the only machine on the market that features an interchangeable coating device allowing customers to choose the powder spreading system best suited to their needs. Customers can select either a scraper system or a roller system, with the latter providing better repeatability for some medium powder applications.

Software and configuration options

Embedded in the machine is AddUp’s NCore software, which is capable of processing large production files of more than 80GB in one go to facilitate the printing of complex parts.

Another software feature included with the FormUp 350 is AddUp Dashboards, which allows for traceability and analysis of production data by tracking some 80 manufacturing parameters and automatically editing production conformity reports. The software continuously monitors the power emitted by the machine’s lasers, the temperature of the fusion process, and provides real-time analysis of the powder spreading quality to check for defects.

Available in four configurations, the printer can be tailored and upgraded to the user’s needs and requirements at any time due to its modular design.

The STARTER configuration brings together the essentials for research and development activities with non-reactive powders, while the EFFICIENCY model is suited to those getting started in 3D printing with the offer of a wider range of powders.

The PRODUCTIVITY configuration is designed for high-level production and industrialization, equipped with four lasers and an autonomous powder module. Finally, the ADVANCED model is designed for expert users looking to achieve high levels of productivity, quality, and monitoring of the manufacturing process.

Technical specifications and pricing

| Machine Dimensions (without powder device) | L 2.55 x W 2.2 x H 2.32 m, weight: 4t |

| Build volume | L 350 x W 350 x H 350 mm, 43l |

| Gas type | Argon or nitrogen with programmable control of oxygen level |

| Laminar flow | Adjustable from 0.5 to 3m/s |

| Laser glasses protection | Cross Jet system, up to 4 x 500W Ytterbium continuous fiber lasers (1070nm), spot diameter 70µm |

| Optical chain | 100% platform coverage by each laser, 3D scanners: 2 axis for X/Y displacements +1 axis for focal adjustment, max speed of 10m/s, 35µm accuracy |

| Visualization | Supervision camera, camera for HD pictures (optional) |

| Powder recoating device | Bidirectional Scraper (rigid blade, brush or silicon) or roller |

| Part properties | Precision: up to 1.0mm, Density: up to 99.99% |

| Heated platform | up to 200°C, cooling system to improve temperature drop time after production |

| Standard powder module | For non-reactive and middle size powders |

| Autonomous powder module | For all types of powder, inerted condition, sieving device integrated, powder recovery during production, glove box, inerted vacuum integrated |

| Fume and fusion residus management | Filtration device with automatic unclogging system, calcium carbonate residus passivation, filters lifetime > 3 years |

| Cooling device | Air/water |

| Interoperability | OPC-UA / MQTT (optional) |

| CAM solutions | AddUp Manager or NTwin |

| Simulation software | Distorsion Simulation AddOn (optional) |

| Monitoring | AddUp Dashboards (optional), recoating monitoring (optional), melting monitoring (optional) |

| Remote maintenance | AddUp Remote Control |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the FormUp 350 3D printer. Photo via AddUp.