CARMAT, a French company dedicated to developing a fully artificial heart, has signed a partnership agreement with OEM AddUp, a joint 3D printing venture between Michelin Group and Fives.

The aim of the partnership is to “strengthen the industrial development of the CARMAT heart” and to prepare the company for “large scale production” of its artificial hearts.

CARMAT’s heart to heart

Even though the first successful human-to-human heart transplant was successfully completed by Dr. Christiaan Barnard in 1967, there is a limited availability of transplantable hearts to help patients suffering from irreversible bi-ventricular heart failure.

CARMAT is aiming to produce artificial hearts for some of the estimated 15 million Europeans and 6 million Americans suffering from irreversible heart failure. It hopes to improve patients’ quality of life and to help eliminate costs of repeated hospitalizations.

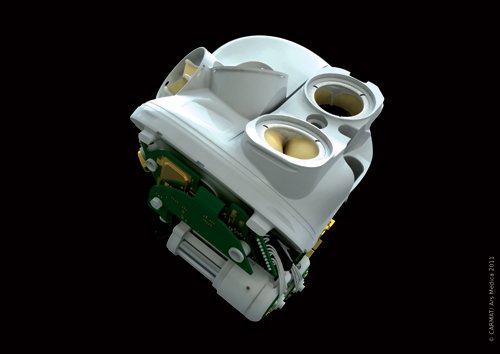

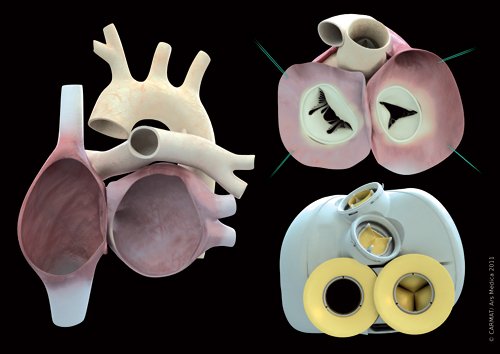

The challenges facing CARMAT include compatibility, auto-adjustment of the heart to the patient’s physiological needs, effective miniaturisation, and developing a suitable portable energy source. A limited number of patients have received early trial versions of the hearts, with varying results.

3D printing as a pacemaker

To address these issues, CARMAT has so far enlisted the expertise of surgeon Alain Carpentier, the inventor of Carpentier-Edwards aortic heart valves, and the engineering services of aircraft manufacturer and primary shareholder Airbus.

With 3D printing technology, CARMAT is particularly looking to develop a design with optimized anatomical interfaces compatible with the rest of a patient’s anatomy, and a design that incorporates fewer components to reduce the risk of blood clots.

Citing the cooperation between “industrial and medical fields” in producing CARMAT’s earlier designs, CARMAT CEO Stéphane Piat stated that the agreement would help the company “accelerate our industrialization and secure our project” helping “longer-term evolutions in our industrial and technical needs.”

AddUp’s 3D printing Expertise

AddUp, previously known as “Fives-Michelin Additive Solutions” (FMAS), has previously partnered with Sonaca Group to develop 3D printed Titanium components for the aerospace industry.

Following its name change, AddUp has also been involved in producing 3D printed tire molds to help produce longer-lasting tires even at low tread depth. Earlier this year, it unveiled a DLM 3D printing metal machine, the FormUp 350.

AddUp CEO Vincent Ferreiro stated that he was “delighted to have the opportunity to associate our unique additive manufacturing technology with a medical project as innovative…as CARMAT,” citing AddUp’s previous success in taking conceptual projects from the “feasibility stage to…industrialization.”

The beat goes on

ETH Zurich 3D produced the world’s first entirely artificial soft heart using 3D printing earlier this year. Although the silicone that was used to make the heart has a lifespan of less than an hour, the project has opened up doors in artificial organ development.

Other 3D printed hearts, such as the one produced at Georgia Tech, have been integral to medical research.

For more information on the development of artificial organs using 3D printing, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows A CARMAT technician inspecting an artificial heart. Photo via AFP.