Open wide… 3D printing technology is steadily making way within the dental industry, as 3D printing companies such as EnvisionTEC and Stratasys remain busy innovating both printers and materials made for safe use in the human mouth. In fact, last year, SmartTech reported that, by 2020, 3D printing technology will make-up about $3.1 billion of the massive and wide-ranging dental industry. Now, it’s one thing to advance the tools that our dentist and orthodontist use when keeping our teeth and gums in check, but what if 3D printing allowed us to do our own dentist work at a more affordable cost… at home.

Well, 3D artist Amos Dudley may have a solution, although he currently DOES NOT recommend trying the following at home. As scientifically proven for quite a while now, it’s pretty widely accepted that the more you smile, the happier you will feel. Unfortunately for Dudley, he was extremely self-conscious about his teeth, which were slightly crooked, and this led him to shine his pearly whites a bit less often than he should have.

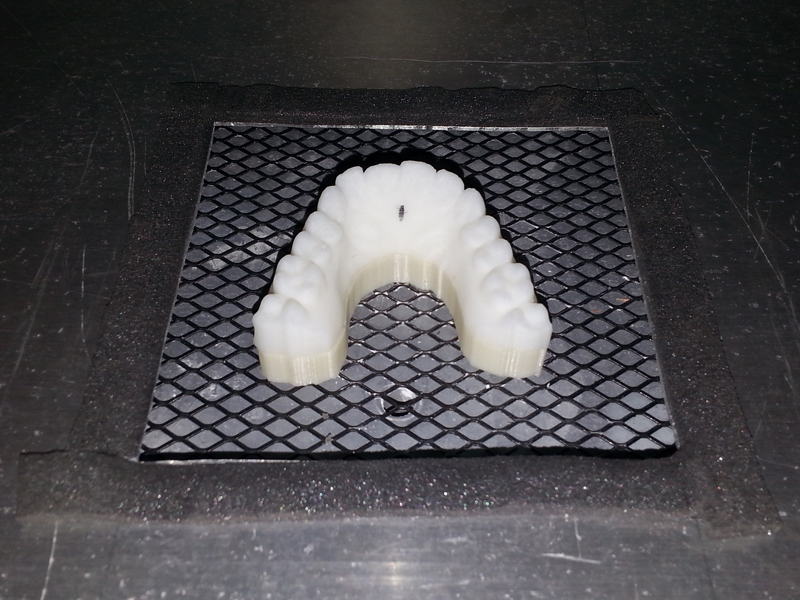

In true maker fashion, instead of taking his issue up with his local dentist, Dudley decided to take matter into his own hands. He first created a mold of his teeth using alginate powder, Permastone, and a 3D printed impression tray, which helped him realize the specific issues of his crooked incisors. Obviously, doing your own dental work is a risky endeavor (again, Dudley recommends NOT trying this on your own), so Dudley deeply researched the professional process for clear orthodontic alignment before attempting the self-procedure.

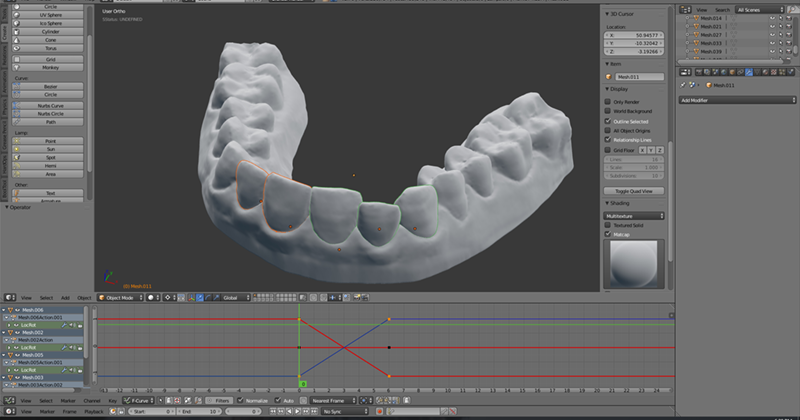

What he discovered was that, with the proper orthodontic knowledge, a 3D scanner, a mold of the teeth, CAD software, a high resolution 3D printer, retainer material, and a vacuum forming machine – most of which Dudley already possessed – he could attempt to set his teeth straight in an affordable DIY style. In order to achieve the necessary accuracy in the print, Dudley opted to use a Stratasys Dimension 1200es printer, but also felt that a SLA printer such as the Formlabs Form2 could do the trick. After creating the mold, he laser scanned it with a NextEngine machine and turned the Permastone-based mold into an STL file.

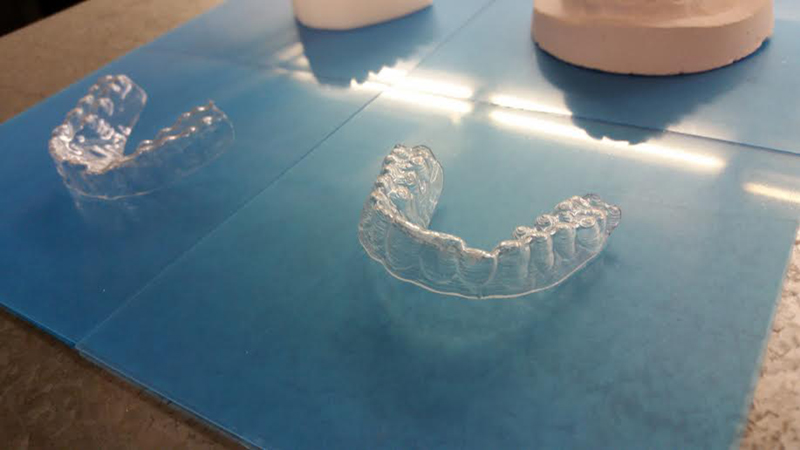

After 3D printing the aligner steps and the ‘riser’, which helps control the potential draping effect from taking ahold of the vacuum forming plastic, he vacuum formed the retainer. Dudley then used a Dremel with a sanding drum to smooth out the edges, which protects the gums from potential irritation. Together, these 3D printed pieces helped to form a perfectly sized retainer for Dudley’s teeth, proving that, with great caution and education, it is possible to be your own orthodontist!

“They’re much more comfortable than braces, and fit my teeth quite well. I was pleased to find, when I put the first one on, that it only seemed to put any noticeable pressure on the teeth that I planned to move- a success! I’ve been wearing them all day and all night for 16 weeks, only taking them out to eat,” Dudley writes in his blog. “And, most importantly, I feel like I can freely smile again. That’s what’s most important.”