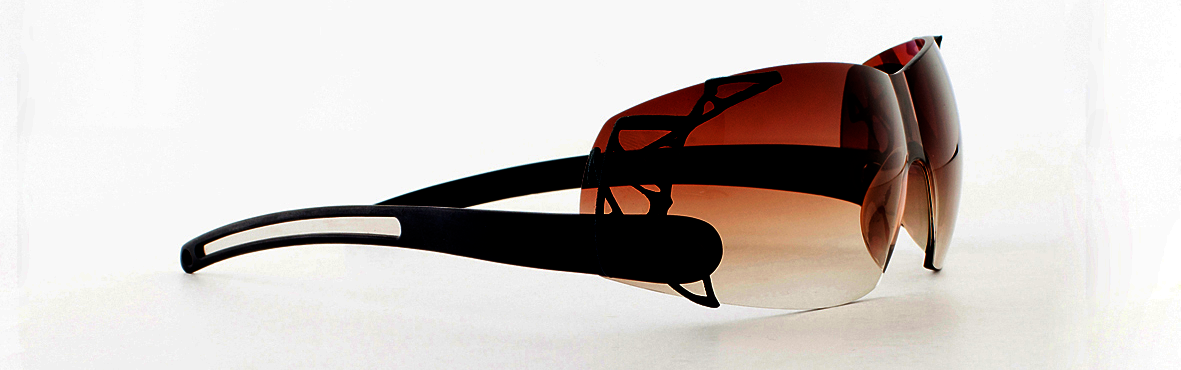

Hoet Design Studios’ new line of sunglasses uses a 3D printed clip system to hold them together, allowing the wearer to remove and replace various decorative accents.

When designer Dieke Hoet designed her new Cabrio Collection line of eyewear, she ran into several constraints that limited her ability to create the sunglasses that she wanted. So she turned to Materialise for help exploring 3D printing to overcome current manufacturing and prototyping constraints and limitations.

“Since 3D Printing offers a great deal of flexibility to create unusual and intricate shapes, we had the freedom to design what we drew on paper, without modifying it in production. That’s why the design started from lines rather than surfaces.” Explained Hoet “The result is a curved open structure that no other technology would have been able to produce.”

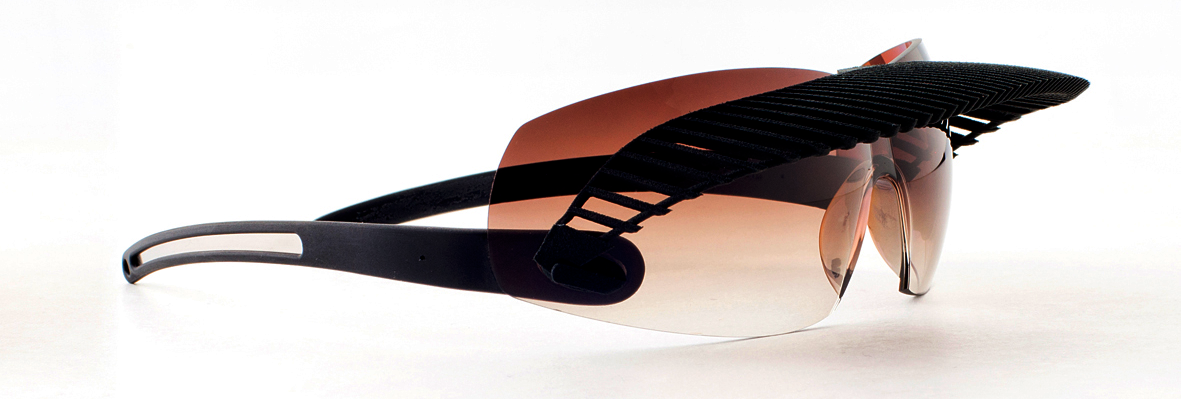

Inspired by the new clip system and how well it worked, Hoet took her designs further and started to design a series of eyecatchers, visors and decorative accessories that could be fitted onto the glasses to achieve different looks depending on your mood or specific needs.

You can see more examples of the 3D printed sunglasses from the Cabrio Collection on their website.