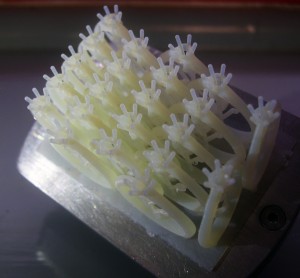

DELCAM will demonstrate their new ArtCAM JewelSmith software, with 3D printing support, by fabricating casts for jewelry using the Ember 3D printer from Autodesk at Inhorgenta Munich, which takes place February 20-23rd in Munich.

Renate Wittgenstein, Product Manager of Inhorgenta Munich, commented on the forthcoming trade show saying,“Inhorgenta Munich, to be held from 20 to 23 February 2015 at the Munich exhibition grounds, will present the current trends in men’s jewelry. Some of our exhibitors have specifically specialized themselves in men’s jewelry, while others reserve more space for this segment in their latest collections. This market has continuously grown in the last few years and, with the support of testimonials, is becoming more and more respectable.”

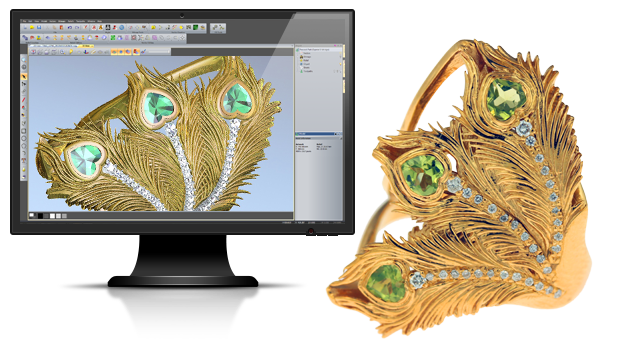

ArtCAM JewelSmith was created to give jewelry manufacturers and designers a set of more powerful tools to increase productivity, help them cycle through the iterative process faster, and quickly create new designs. The software comes with a gem library and the powerful Keyshot rendering system so that customers and retailers can view high-resolution life-like images. The renders can also be used for catalogs or other marketing materials.

The Ember was a surprise entry into 3D printing universe, and there is a lot of intrigue over Spark, Autodesk’s open software platform. Autodesk began taking orders for Ember the first week of December, and you can sign up right now to get your Ember Explorer Access Pass.

I feel as though, this year, new companies that try and jump on the hype train (of course, it’s fine to be genuinely excited, though) will have certain expectations to meet in terms of the user’s experience. It’s all about improving the actual technology from end-to-end, because the hype isn’t very helpful, which is why it doesn’t last. If you saw Carl Bass talk at CES 2015 this year (embedded below), I personally believe that you can really see the good intent of Autodesk releasing everything as open: open software platform (Spark), open hardware (Ember) and open materials in the right hands could yield some realistic solutions to common criticisms of 3D printing: reliability, speed, and materials. They seem hellbent on improving the 3D printing experience as a whole, and they do this in the right way, which is being transparent about their own experiences with 3D printers, and offering up their best openly and freely.