Atlanta, Georgia tech company United Sciences showed off some impressive new 3D scanning technology at CES 2015. The handheld 3D scanning device is the first mobile scanner that can accurately capture the entire inner ear, making any wearables completely customized to the wearer. By combining the detailed 3D scan with a bank of 3D printers, it is possible to produce a pair of custom earbuds in about an hour.

While 3D scanning and 3D printing have been employed in the hearing aid industry for a decade, creating those in-ear devices often took weeks and relied on imprecise scans of silicon molds to create them. However, the new scanning technology developed by United Sciences completely eliminates those pitfalls with a simple handheld device,actually made up of three individual scanners, each serving a different purpose.

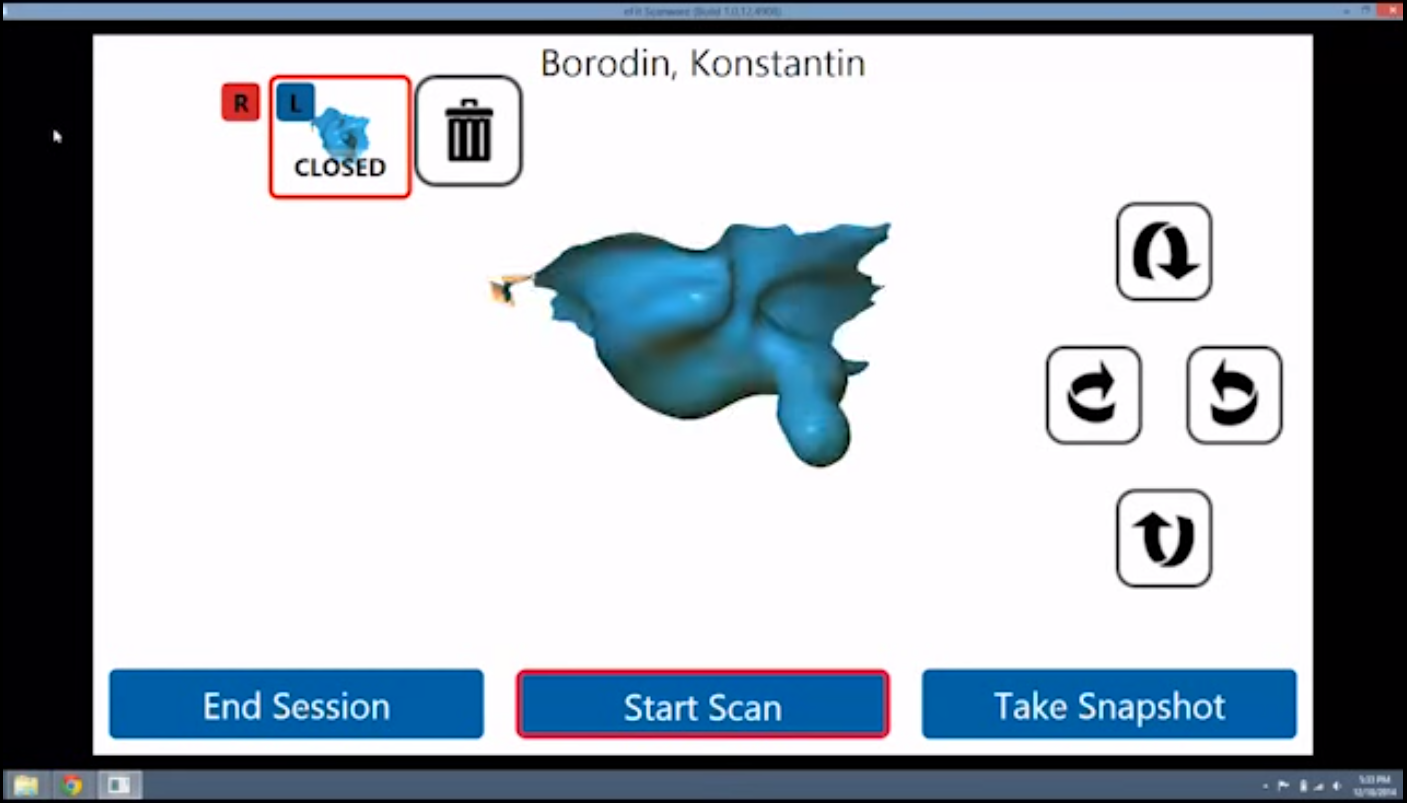

The first sensor tracks the patient’s head to compensate for any movements that could distort the scan. The second is a ring shaped laser that is shot into the ear canal, mapping it completely to send the data back to a screen, so that a technician can make sure the entire inner-surface has been captured. The final scanner is a simple line laser that maps the outer ear and joins it to the inner ear for a complete digital model.

The entire scanning process takes about five minutes in total, and, once captured, the data can be sent to a technician, who optimally places any necessary electronics and then divides the model into four parts. Each section is turned into a mold and 3Dprinted individually. This method of real-time manufacturing reduces the printing time to about 20 minutes. Once the molds are complete, they can be filled with quick drying silicone, and the device can quickly be assembled.

Here is a video of the entire scan and 3D printing process, as demonstrated at this year’s Consumer Electronics Show in Las Vegas:

“We are excited to debut this revolutionary scanning technology which we feel holds great promise for becoming the industry standard which will enable the next generation of in-ear devices,” said CEO of United Sciences Sam Kellett, Jr. of his new technology. “The precise dimensions captured by our scanner will forever replace the need for silicone impressions and give users a product with fit, comfort and effectiveness never before possible.”

The devices that can be created with the new handheld 3D scanner extend far beyond earbuds and headphones. Smaller and more comfortable hearing aid devices can be produced, as well as customized sound cancelling ear protection. In-ear wearables like bluetooth devices may also easily be created.

More interesting than these wearables, however, is the ability to create an entire new generation of biometric data gathering devices. Because of the positioning of the ear within the body, custom wearables can be created to collect EEG, EOG, & EMG data to monitor information like a patient’s heart rate, sleep patterns, brain activity and even oxygen levels.