Award-winning, Californian sustainable metal powder developer and MolyWorks subsidiary Continuum has raised $36 million in funding.

Designed to address 3D printing and metal injection molding (MIM) system users, the firm’s ‘Optipowder’ feedstocks are formulated entirely from recycled materials. Having gained the backing of Ara Partners, a private equity firm specializing in industrial decarbonization, Continuum now aims to scale its capacity to meet growing customer demand.

“The additive manufacturing powder market is expected to more than triple over the next five years as the 3D printing industry hits a commercial inflection point,” said Phil Ward, Continuum’s CEO. “Ara’s investment allows us to supply the industry’s growth with a sustainable solution.”

“Ara has demonstrated experience scaling businesses that support the transition to a circular economy, and we look forward to working with them as a strategic and financial partner.”

Continuum’s circular manufacturing aims

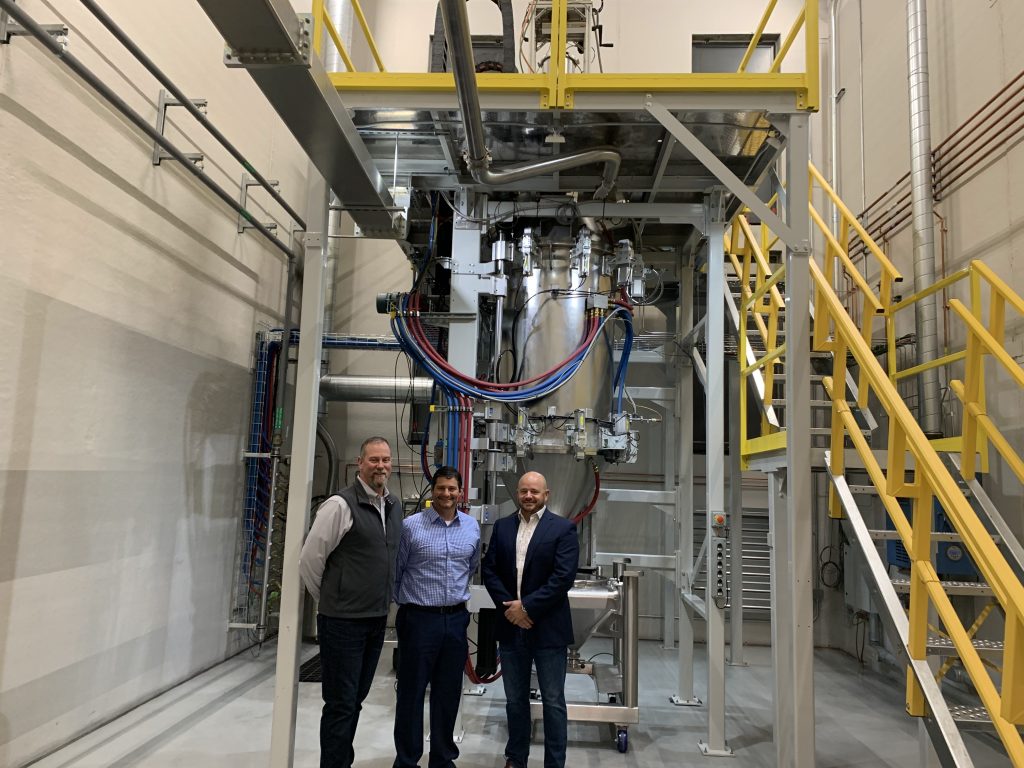

Continuum is the newly-minted commercial arm of the MolyWorks Materials Corporation, an eco-friendly metal 3D printing material developer that has already established deep roots in the industry. The company has done so via the development of Greyhound Technology, a process marketed in the form of a plasma atomization system capable of repurposing metal goods, with a much smaller footprint than many traditional technologies allow.

A winner in the sustainability category of this year’s 3D Printing Industry Awards, MolyWorks continues to expand on the applications of its eco-friendly powders. Earlier this year, MolyWorks gained ISO:9001-2015 and AS: 9100AD certification for its Greyhound system, before signing an MoU with Singapore Polytechnic to accelerate the use of recycled metals in maritime and offshore use cases.

Much like its parent firm, Continuum specializes in accelerating the adoption of circular manufacturing. In particular, the company says it seeks to “address the missing link in the circular metal supply chain,” through its unique ability to produce high-quality materials for engineered parts through 100% recycled and responsibly-sourced materials.

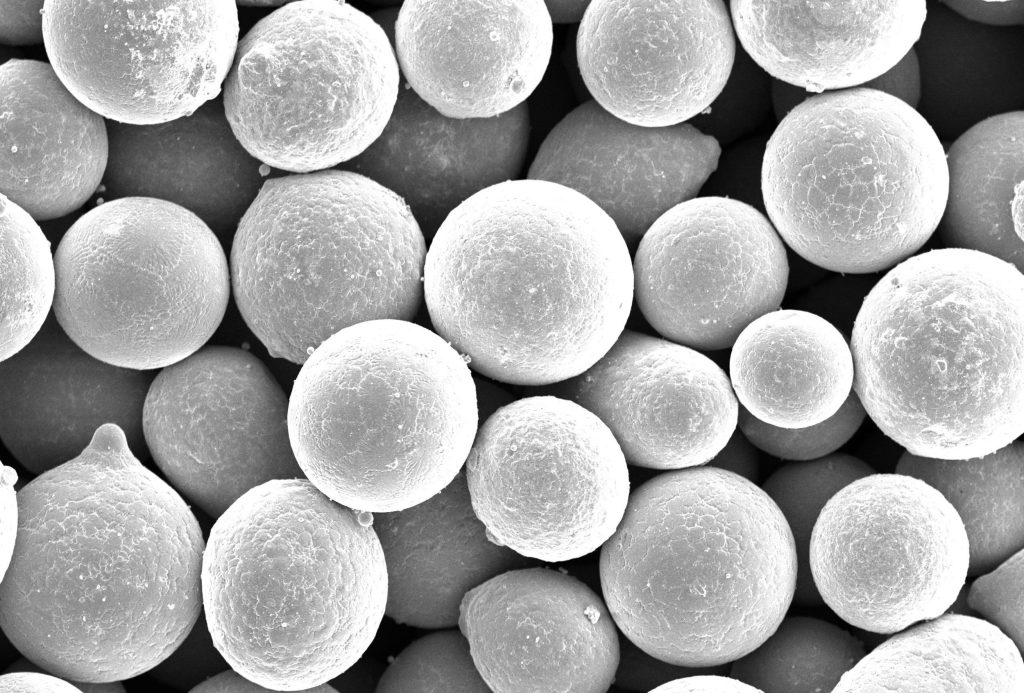

Manufactured via the same Greyhound foundry system used to produce MolyWorks’ materials, Continuum’s Optipowder is said to offer “complete traceability and maximum purity.” These metals, which now span over 30 different alloys, are also ISO/AS certified and engineered for use with cold spray, 3D printing, metal injection molding and more.

Currently, Continuum promotes four metal variations via its website: a nickel-based superalloy, stainless steel 316L, Ti64 grade 5 and Ti64 grade 23. Each of these are understood to work with industry-leading machines, developed by EOS, 3D Systems, Renishaw, Optomec, MELD, Arcam, Concept Laser and Additive Industries.

“Creating a circular metals economy is critical to meeting the world’s sustainability goals. Titanium, stainless steel, and inconel alone account for tens of millions of tons of scrap metal each year that will need to be repurposed in the new sustainable economy,” said Cory Steffek, Partner at Ara. “We are incredibly excited about the opportunity to help Continuum scale and address these enormous hurdles.”

AM’s recycled metals market

As sustainability continues to rise to the top of metal 3D printing firms’ agendas, demand for more circular materials has grown in tandem. One of those seeking to address this clamor for eco-friendly powders, is 6K Additive. As explained during 3D Printing Industry’s visit to 6K Additive earlier this year, the firm’s UniMelt reactors allow up to to 100% of millings, turnings and other discarded metals to be reused.

In April 2022, Epson Atmix’s new metal powder recycling facility also got the go ahead. Set to open by 2025, the complex is expected to feature facilities that enable scrap metals to be turned into usable 3D printing powders. The Epson subsidiary’s reveal closely followed the announcement that Epson is finally launching its debut 3D printer, eight years after first signaling its intention to do so.

IperionX’s 3D printing titaniums continue to gain traction in the industry as well. The company went public on the Nasdaq exchange earlier this year, in a deal that was expected to provide it with increased liquidity, and expose it to new investors.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows imaging of one of Continuum’s recycled stainless steel metal powders. Image via Continuum.