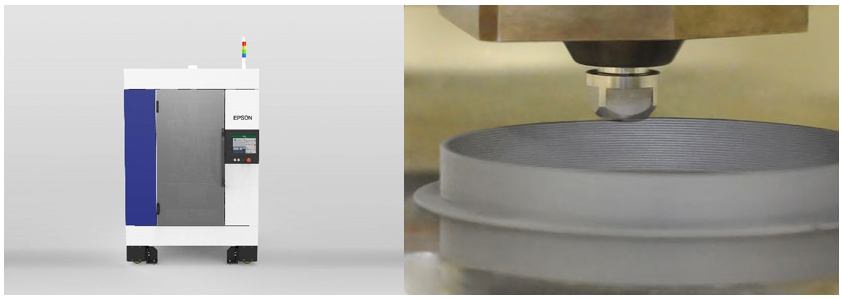

Seiko Epson Corporation (Epson), a multinational Japanese electronics firm specializing in 2D printing technology, has announced the launch of its debut industrial-grade 3D printer.

The unveiling of the unnamed extrusion-based system comes eight years after the company announced plans to move into additive manufacturing.

With its first prototype now ready to showcase, Epson will exhibit the 3D printer at its booth at International Robot Exhibition 2022 in Japan. The show opens on March 9th at Tokyo Big Sight.

According to Epson, the novelty of the machine lies in its unique flat screw extrusion technology, which allows the system to 3D print a wide variety of pellet materials. This includes resin granules, metal pellets, and high-performance thermoplastics like PEEK.

Epson’s move into additive manufacturing

Epson is already a major player in the 2D printing space. Back in 2014, the company’s president Minoru Usui stated that it would eventually transition into the 3D printing market too. However, he was sure to note that he wasn’t happy with the state of 3D printing technology at the time and didn’t want to push out a flawed system as fast as possible. With product quality in mind, the move would take at least five years to complete.

He also asserted that the firm’s debut 3D printer would be both large-scale and industrial, granting users the ability to print with almost any material. He said, “We are developing our own printers, but our aim is to change everything. When it comes to 3D printing… we want our machines to make anything. One of our goals for digital printing technology is the ability to print any materials.”

In 2017, Epson’s long-term 3D printing dream edged even closer when the firm announced concrete plans to move into the sector as part of its Vision 2025 Strategy.

Flat screw extrusion 3D printing

Although details are scarce for now, Epson’s new 3D printer aims to fabricate ‘strong and accurate’ industrial parts for both functional prototyping and low-volume end-use series production applications. Where conventional industrial systems may require special materials to complement the machines’ capabilities, Epson’s machine will be able to print with all manner of ‘commonly available third party’ pellets.

The firm attributes this to a novel material extrusion method that leverages a flat screw (an inline screw with a flattened configuration) as a nozzle, much like the ones found in Epson’s injection molding machines. The list of compatible granules includes both metals and polymers, and even environmentally-friendly biomass pellets.

Pellet materials are generally significantly cheaper than their filament-form counterparts, so the system is expected to enable huge cost savings for manufacturers. Granulated feedstocks also lend themselves to much faster print speeds, so lead times are also expected to accelerate.

Additionally, the printer can carefully control the volume of material extruded by regulating both the pressure within the printhead and the action of a valve in combination with the feed rate. Epson has even developed a special mechanism for controlling the temperature at the surface of the printed part, which is necessary to improve strength during the printing process.

The company wrote, “This 3D printer is thus engineered to manufacture strong, accurate objects with commonly available materials, facilitating printer use in the production of industrial parts for final products. It is ideally suited to mass customization, as it can produce small batches of parts tailored to customers’ needs with higher quality, shorter lead times, and at a fraction of the cost of traditional manufacturing processes.”

Epson aims to commercialize its 3D printer after making a number of refinements to the technology. During this time, the firm will also use the system internally to 3D print parts for commercial and industrial equipment.

The pellet-based extrusion niche

Although the pellet 3D printing space is nowhere near as active as conventional FFF, the technology can offer major advantages when it comes to material compatibility, processing speeds, and material costs. Late last year, AIM3D, a Germany-based developer of multi-material 3D printing technology, announced the launch of its latest pellet 3D printer. Operating on the firm’s proprietary composite extrusion modeling (CEM) process, the ExAM 510 can print with up to three different injection molding pellet materials simultaneously.

Around the same time, 3D printer OEM WASP also added several new products to its large-format 3D printing portfolio. The company’s 3MT HDP and 4070 HDP systems are designed to process recycled polymer granules in a fast, precise, cost-effective and ultimately more sustainable way.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printer’s unique flat screw technology. Photo via Epson.