A group of industrial 3D printing firms Zymergen, Hexagon, 3D4Makers, and AON3D have performed an experiment on the new 3D printing polymer, Z2 Polyimide.

The novel, easy-to-3D print formulation of Polyimide offered impressive findings in experiments assisted by The Royal Netherlands Navy‘s Expertise Centre Additive Manufacturing (ECAM): a high-strength, highly isotropic AM polymer part that, despite its minimal cross-section (2 cm wide), survived 432 kg of load before failure. Hexagon’s Digimat AM software was used to perform predictive modeling and simulation on a tie-down bracket for military cargo planes, a tool that assists engineers decrease overall lead times and simulate end-part performance. The part was then mechanically tested after being 3D printed in Z2 Polyimide with 100% infill on the AON M2+ High-Temperature Industrial 3D Printer.

What insights did the experiment provide?

The Z2 Polyimide part printed on the AON M2+ ruptured precisely where the Digimat AM software anticipated, and with a fracture that propagated across various layers rather than just one. While Z2 Polyimide has a tensile modulus similar to ULTEM™ 9085, it has high strength and elongation at break properties. This means that Z2 has significantly higher interlayer weld strength and part isotropy than ULTEM™. During testing, a part fractured through multiple layers in two locations, implying that the layers had followed the stress front in accordance with the overall structure, rather than inter-layer welds.

With its improved strength and isotropy, as well as the possibility of meeting UL94 V0 and FAR 25.853 (FST) requirements (testing in progress), Z2 Polyimide has the potential to be a ULTEM™ alternative.

Subsequently, the results of this experiment show that material breakthroughs as well as open material industrial 3D printers capable of printing them are rapidly advancing the 3D printing industry, while closed systems lag years behind, says AON3D.

High-performance engineering polymers

A review by 3DPI states that the market for polymer 3D printing is expanding rapidly, with findings that polymer powder consumption increased by 43.3% in 2021, surpassing photopolymer resins as the most commonly used 3D printing material. HSS is a powder-based 3D printing process similar to binder jetting that was developed in the early 2000s by Neil Hopkinson at the University of Loughborough and Sylvia Monsheimer at Evonik. It is well-known for its quick print speeds and large-part production capabilities.

Since acquiring a commercialization license for the technology in 2016, voxeljet developed its own version of HSS and launched its first HSS 3D printer in 2017. Since then, the company has expanded its product line with several HSS-powered 3D printers, including the VX200 HSS and VX1000 HSS. Similarly, under the binder jet banner, MJF is a sibling. HP provides engineering-grade polymer parts for functional prototyping as well as end-use production, with applications in industries such as automotive.

Previously, Roboze, an industrial 3D printer manufacturer, announced the release of two 3D printers along with two printing filaments. The novel PRO series, which replaces the older Roboze One product line, includes the One PRO and Plus PRO machines, both of which use Roboze’s trademark high-temperature FFF technology. These updates are primarily intended for functional prototyping and tooling applications utilizing high-performance polymer and composite materials. In addition to the systems, the company expanded its filament portfolio with the introduction of Roboze PEKK and Roboze ToolingX CF.

Elsewhere, Solvay, a Belgian chemical company, announced the addition of two high-performance 3D printing polymers to e-Xstream engineering’s Digimat-AM material simulation platform. Carbon fiber-reinforced PEEK and high-toughness PPSU are among the novel additions. Solvay hoped to widen the potential of these materials and improve its market position by offering them through Digimat-AM.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

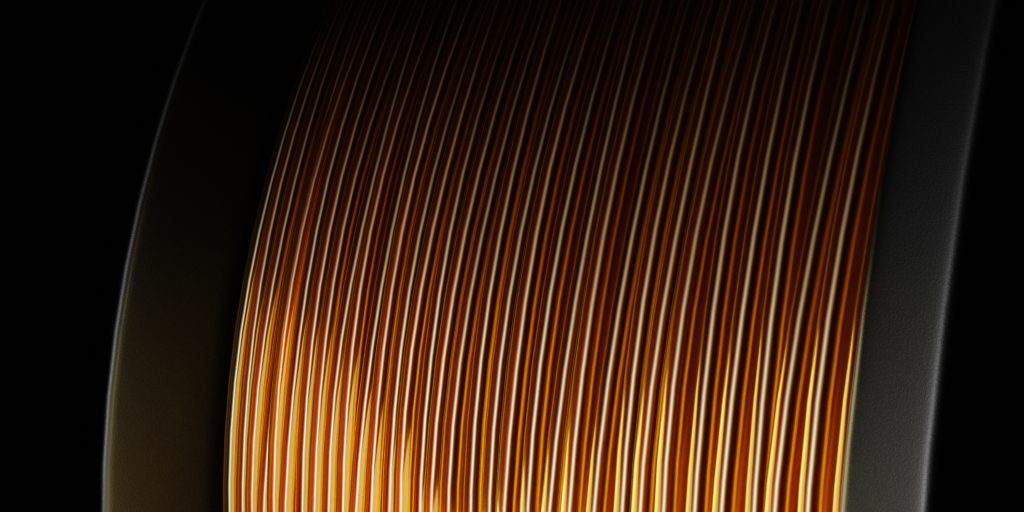

Feature image shows Linear Test Orientation performed by the companies. Image via AON3D.