In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new 3D printing partnerships, business updates, new additive manufacturing materials, novel 3D printing applications, and facility certifications.

Read on for the most recent updates from Nexeo Plastics, 3D Metalforge, Filamentive, Local Motors, Oerlikon, Essentium, Sintavia, SPEE3D, Kennametal, MolyWorks, and more.

AMUG Conference Returns – Mask Mandates Lifted, Discount Extended

3D Printing Industry is excited to be returning to the AMUG Conference next month. Chicago, the location for the 2022 AMUG Conference, has lifted its mask mandate and removed proof of vaccination requirements. With these changes, AMUG Conference attendees are free to engage and socialize without a mask or proof of vaccination. The city’s announcement came just days before the cutoff for discounted registration. To allow more time to consider attending the AMUG Conference in light of the change, AMUG has extended the discounted attendee registration period through March 11, 2022.

New 3D printing partnerships from Nexeo Plastics, 3D Metalforge, and Imaginarium

Getting this week’s partnerships news underway is thermoplastic resin distributor Nexeo Plastics, which has announced a distribution agreement with Stora Enso to distribute its renewable biocomposites throughout Europe, including grades for 3D printing. The firm’s biocomposites can be used as renewable alternatives to fossil-based plastics in numerous applications ranging from furniture and storage to food-contact plastic and industrial components.

3D printing service provider 3D Metalforge, meanwhile, has signed a three-year agreement with IKM Measurement Services to promote its products and services to customers in Australia and Southeast Asia. The channel partner agreement forms part of 3D Metalforge’s strategy to expand its presence in the Australian resources, oil and gas, and maritime sectors.

“We are extremely pleased to be collaborating with IKM Measurement Services Australia as part of our strategy to build our sales strategy in Australia and in the oil & gas industry,” said Matthew Waterhouse, 3D Metalforge Managing director. “We can truly offer customers a point of differentiation providing a range of AM-related services from diagnostic, design, part production through to training and cloud IP management; and in this instance, this is a great opportunity to promote our AM technology to IKM Australia’s customers.”

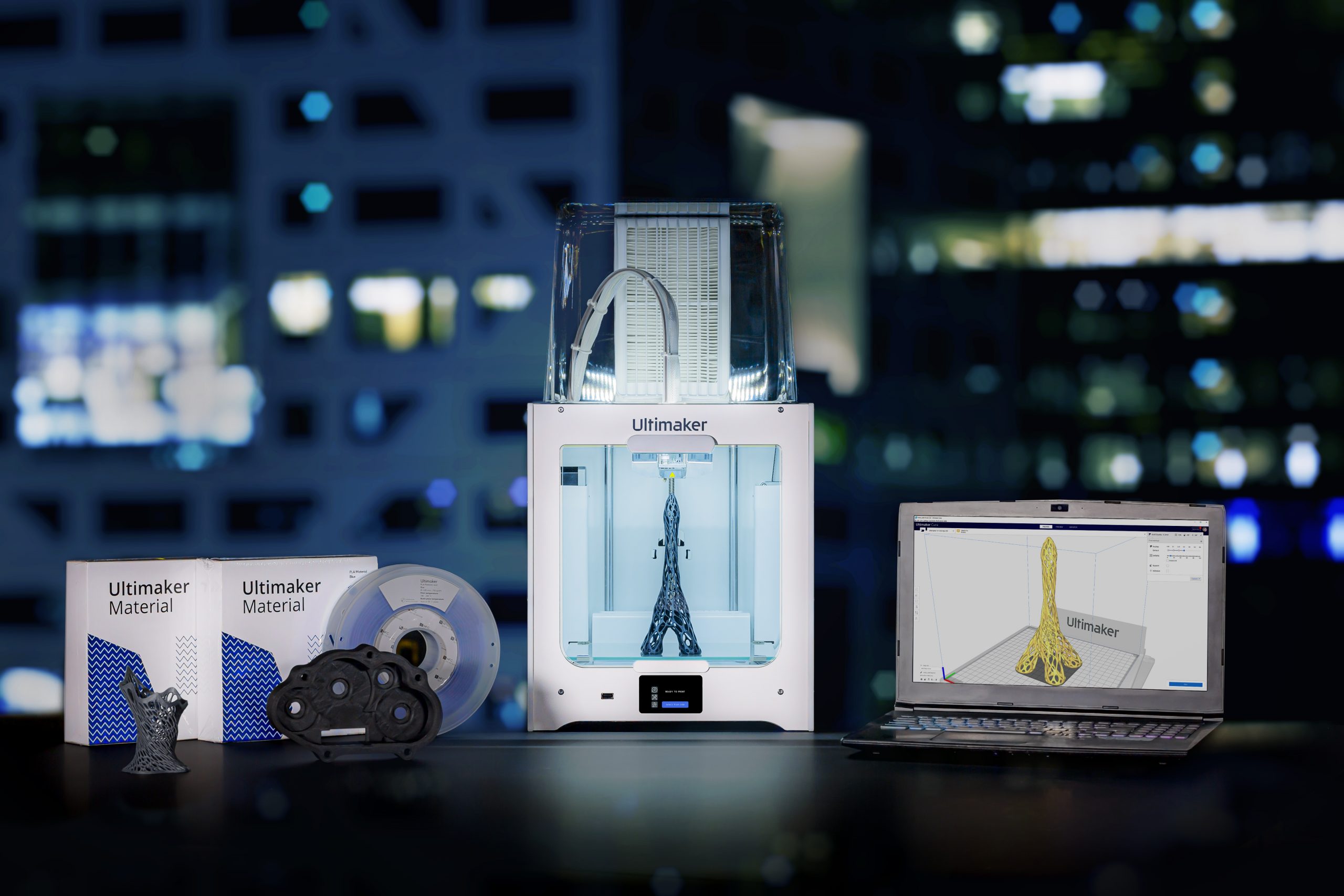

India’s largest rapid prototyping and manufacturing center, Imaginarium, has unveiled its newest desktop and industrial 3D printer range in partnership with 3D printer manufacturer Ultimaker. As part of the Make In India initiative, Imaginarium will have access to Ultimaker’s state-of-the-art equipment and enable the center to focus on production-grade applications and a variety of industries.

Business updates from Local Motors, Oerlikon, Desktop Metal, and Sintavia

Having closed its doors in January, the assets of automotive OEM Local Motors are going up for sale between 15-17th March. A total of 439 lots are up for auction later this month, including the firm’s 3D printed Strati and Swim models, and 13 of its 3D printed “Olli” autonomous shuttles.

Swiss technology group Oerlikon has released its FY 2021 financials, revealing strong growth and margin expansion across both its Surface Solutions and Polymer Processing Solutions divisions, which it expects to continue into 2022. The firm also announced the stepping down of its CEO Roland Fischer due to personal reasons, with Prof. Dr. Michael Suess taking up the role of Executive Chair.

“We grew the company and delivered strong margin expansion in 2021, and expect profitable growth to continue in 2022,” said Fischer. “Operationally, we executed well, efficiently managed cost and successfully mitigated supply chain shortages, driving EBITDA above pre-covid levels. Moreover, we successfully completed two accretive bolt-on acquisitions, further diversified our business and made excellent progress in our sustainability initiatives. The Board will propose a dividend of CHF 0.35 per share at the AGM.

“In 2022, we will continue to execute on our strategy to expand in growth markets, take advantage of recovering markets and focus on cost control. We expect Group sales to be around CHF 2.9 billion and our operational EBITDA margin to be around 17.5%.”

Meanwhile, binder jet 3D printing system provider Desktop Metal has shipped its first Production System P-50 additive manufacturing system to industrial tool and hardware manufacturer Stanley Black & Decker. With the P-50 slated to be up to 100 times faster than traditional PBF technologies, it appears Desktop Metal is coming good on its promise of delivering truly high-throughput 3D printing with the commercialization of the system.

Sintavia, an additive manufacturing service provider for the aerospace sector, has ordered two NXG XII 600 3D printing systems from metal 3D printer manufacturer SLM Solutions. The new additions will help Sintavia to cost-effectively supply “unprecedented demand” for printed metal componentry by manufacturing parts at a rate and quality that it claims is currently unequaled in the industry.

During the testing of the machine, Sintavia successfully fabricated a large Inconel shrouded impeller with an exposure area of more than 50 percent and a weight of 174kgs in less than one week. As soon as the first machine is delivered, the firm says it will be able to enter serial production with the part.

“It is very clear that future flight and launch OEMs will depend on complex mechanical systems enabled by additive technology,” said Brian Neff, Sintavia’s Founder and CEO. “The sheer size and efficiency of the NXG XII 600 platform will greatly accelerate this profound modality shift.

“We are looking forward to unlocking its benefits on behalf of our aerospace, defense, and space customers.”

MolyWorks facility achieves ISO and AS certifications

MolyWorks, a US-based company focused on the circular economy for metal, has announced its Greyhound facility has received ISO:9001-2015 and AS: 9100AD certifications for the production of additive manufacturing metal powders.

“These certifications indicate Molyworks’ commitment to provide the highest trusted products and services to our customers,” said Christopher Eonta, MolyWorks Founder.

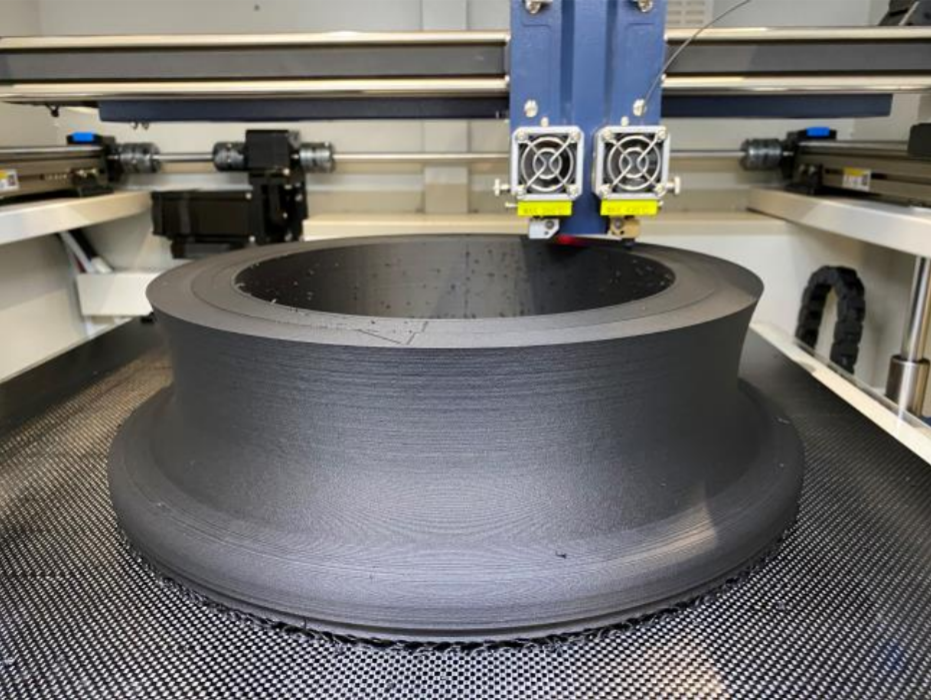

EWI to include SPEE3D machines in new cold spray facility

In more facility news, independent engineering consultancy EWI has announced it will install SPEE3D’s metal 3D printers at its new Cold Spray Center of Excellence, due to open this year.

The WarpSPEE3D printer will be installed and EWI’s Buffalo Manufacturing Works facility in New York in order to support the EWI’s cold spray initiative aiming to advance knowledge and capability for the technology across various manufacturing industries.

New 3D printing materials from Formlabs, Stratasys, Evonik, and Filamentive

Moving onto materials now, and resin-based 3D printer manufacturer Formlabs has introduced its new Nylon 12 GF glass-reinforced plastic powder for its Fuse 1 SLS 3D printer. The powder is suited to the production of stiff and thermally-stable 3D printed parts, and joins the Nylon 12 and Nylon 11 powders in the firm’s SLS materials library.

Nylon 12 GF Powder combines the utility of Nylon 12 with the rigidity and heat resistance of glass filler, making it ideal for applications requiring sustained load-bearing and elevated thermal resistant material properties.

Meanwhile 3D printer manufacturer Stratasys has launched a new water-soluble support material, WSS150, for its J35 and J55 Prime PolyJet 3D printers. WSS150 enables the easy hands-free removal of support material from prints using tap water or a dishwasher without the need for additional chemicals.

“WSS has allowed our customers to more easily adopt and integrate 3D printing into their design processes and workflow and has enabled us to further expand the in-office use and accessibility of 3D printing,” said Oren Zoran, Product Group Director for Stratasys. “Service providers can now manufacture and clean hundreds of parts simultaneously, with minimal labor and with a more environmentally friendly process.

“The ability to easily remove support material is especially crucial when engineers design complex parts with intricate areas, or when architects create designs with thin, small-scale and easily breakable elements that would require time-intense manual post-processing.”

Elsewhere, German chemicals firm Evonik has expanded its VESTAKEEP biomaterials portfolio with a new osteoconductive VESTAKEEP Fusion PEEK filament specially engineered for 3D printing implants. Called VESTAKEEP iC4800 3DF, the filament can be processed in common extrusion-based 3D printing technologies like FFF, and is designed to improve fusion between bone and implants.

Showcasing excellent biocompatibility and biostability, the PEEK filament contains a biphasic calcium phosphate (BCP) additive to achieve its osteoconductivity capability, which allows bone cells to adhere to implants more quickly, which in turn will accelerate bone fusion and subsequently patient recovery.

The last of this week’s materials announcements is from 3D printing filament developer Filamentive, which has announced that its PLA filament line now contains 87 percent recycled material as of 2021 production volumes, more than double that of the production average of 2020. As of February 2022, the firm is now only working with post-industrial recycled material, which is waste diverted from the waste stream during manufacturing processes.

“Despite the pandemic, latest data shows that 3D printing still grew by more than 20 percent,” said Ravi Toor, Managing Director of Filamentive. “As the industry grows substantially, Filamentive is committed to ensuring that the filament market grows sustainably – increasing resource efficiency whilst reducing environmental impact by recycling plastic waste materials that would otherwise go to landfill.”

Essentium research shows confidence in AM

Industrial 3D printer manufacturer Essentium has announced new findings from its independent global research looking at the current and future use of industrial 3D printing. The study found “strong confidence” in additive manufacturing maturity among manufacturing executives, with 96 percent agreeing the industry could save billions in production costs once the technology matures.

More than half of executives taking part in the study believe additive manufacturing will lead to a significant increase in revenue, while nearly all reported that 3D printing allows their designers to be more creative.

NASA recognizes REM Surface Engineering capabilities

REM Surface Engineering has been recognized in NASA’s Spin-Off 2022 publication for its successful technology and capability developments in supporting the NASA Marshall Space Flight Center. Under two Small Business Innovation Research (SBIR) REM developed robotic polishing capabilities for various superalloys in order to improve the surface finish of 3D printed rocket engine components.

The firm developed surface finishing processes for both LPBF and LBP-DED parts printed from Inconel 625 and 718, and also for two novel iron-nickel-based superalloys of interest to NASA for their specific properties relative to high-pressure hydrogen rocket engines, JBK-75 and NASA HR-1.

Novel 3D printing applications from Nebrija University, Kennametal, and Sennheiser

Nebrija University has partnered with steel giant ArcelorMittal to 3D print a hollow tubular steel trellis frame for a motorcycle that is lighter than both aluminum and titanium. The team used a standard powdered steel to produce hollow tubes of between 0.8-1mm in wall thickness, and then integrated this data into an algorithm that automatically created stable geometric shapes.

Industrial tooling and materials provider Kennametal, meanwhile, has introduced a next-generation 3D printed stator bore tool for the machining of aluminum engine housings for electric vehicles (EVs). The latest version of the tool has a newly designed arm structure, a larger center carbon fiber tube, and weighs 20 percent less than the original design at just 7.3kg.

Finally, German audio company Sennheiser has leveraged 3D printing to produce the housings for its new IE 600 earphones. The earphones are fabricated from ZR01 amorphous zirconium, an ultra-hard metal with a glass-like atomic structure that is reportedly three times as strong as high-quality steel.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Nebrija University’s 3D printed hollow tubular steel trellis motorcycle frame with the sliced logo.