In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments and partnerships in the 3D printing sector.

Today’s edition includes several 3D printing partnerships and business deals, two new ultra-low porosity 3D printing powders, a new AR platform for 3D models, and an award-winning 3D printed water faucet.

Read on for the most recent updates from umati, Equispheres, Taiyo Nippon Sanso, MolyWorks Materials, Singapore Polytechnic, CairnSurgical, Amnovis, Computer Aided Technology, Onulis, DuPont, Phillips, Uniformity Labs, 6K and more.

New partnerships in 3D printing

We kick things off with the latest partnerships in the additive manufacturing sector. LCD 3D printer OEM Photocentric has partnered with umati to improve the connectivity of its 3D printing systems. As part of the partnership, users will be able to integrate Photocentric’s 3D printers with third-party MES and facility management systems via umati’s standardized interfaces based on OPC Unified Architecture. Ultimately, customers will be able to combine Photocentric devices with machinery from multiple manufacturers within the umati community.

“Thanks to the open-source nature of umati along with a rapidly growing community of industry experts, we believe this standardized interface will soon become the go-to for machinery connectivity across all sectors of mechanical engineering,” says Doug Finlay, Lead Software Dev at Photocentric. “We are excited to see Umati’s notion of a common language support the sharing of machine data between companies to encourage continuous learning and process optimization.”

3D printer manufacturer Aconity3D has signed a deal to distribute Canadian materials firm Equispheres’ high-performance aluminum 3D printing powders to its customers. The agreement comes as Aconity3D and Equispheres have managed to achieve excellent print speeds on the AconityTWO printer using Equispheres’ proprietary alloy powders.

“Our material has proven to work well with Aconity3D equipment,” says Evan Butler-Jones, VP of Product & Strategy at Equispheres. “This non-exclusive agreement allows Aconity3D to provide its customers with a powder qualified on Aconity3D printing equipment, that has been shown to achieve higher build rates than traditional aluminum powders when combined with the precision and power of Aconity3D’s equipment.”

Equispheres has also signed a strategic partnership agreement with Taiyo Nippon Sanso Corporation (TNSC), a Japanese gas and welding company. The firms will work to increase the adoption of metal 3D printing in Japan, all while exposing Equispheres to the Asian market.

MolyWorks Materials Corporation signed a new Memorandum of Understanding with Singapore Polytechnic to accelerate the use of metal 3D printing and recycling in the region’s maritime and offshore sectors. As part of the MoU, both parties will develop new 3D printing processes and materials for use in shipbuilding, as well as create a shared database for AM data. They will also provide workforce training to ensure that industry professionals are well-equipped to adopt and implement 3D printing.

Georgina Phua, Deputy Principal at Singapore Polytechnic, said, “Additive manufacturing is a promising technology that creates opportunities in driving sustainability and transforming sustainable business practices in the maritime and offshore sector. This is an excellent collaboration where Singapore Polytechnic‘s Innovation Centre for Additive Manufacturing will contribute and share its expertise and facilities to accelerate the design maturity and adoption of additive manufacturing in Singapore.”

In Europe, medical device firm CairnSurgical has selected Belgian contract manufacturer Amnovis to 3D print its patient-specific Breast Cancer Locator (BCL). The device is a custom surgical guide designed to help surgeons locate and remove breast tumors more precisely during lumpectomies. Available for commercial use in the EU, the BCL will be 3D printed using SLA technology.

David Danielsen, CEO of CairnSurgical, said, “We chose Amnovis as our operations partner because we recognised that their expertise in medical device 3D printing and their strong focus on quality systems was the right combination for us to enable the commercial launch of the BCL surgical guidance system in Europe.”

Finally, tech supplier Computer Aided Technology has signed a distribution agreement to bring Onulis’ WRAP (Waste Resin Axial Printing) W7500 device to North America. The environmentally-conscious system serves to solidify unused UV resins from SLA and PolyJet 3D printers to make them safe for disposal.

The latest 3D printer investments

In purchasing news, Azul 3D has delivered one of its LAKE 3D printers to DuPont Electronics & Industrial. The firms have been working together for over a year to prepare DuPont to test the system onsite at its DuPont Experimental Station in Wilmington, Del. Based on Azul 3D’s high-area rapid printing (HARP) technology, the LAKE is a resin printer capable of printing at speeds of up to 18” an hour.

“The collaboration with DuPont has been incredibly productive. The shipment of a LAKE printer to DuPont further validates the industrial capabilities of Azul 3D’s technology and materials,” said Cody Petersen, CEO of Azul 3D. “This is just the start of our effort to fully transform mass production in the polymer manufacturing space.”

Elsewhere, Hebei Jingye Additive Manufacturing Technology has invested in several quad-laser EP-M650 3D printers developed by Chinese OEM Eplus3D, which Jingye will use to support its 3D printing service business. The EP-M650 is a large-format powder bed fusion system featuring a build volume of 655 x 655 x 800mm. It can process titanium, aluminum, nickel alloys, maraging steel, stainless steel, and chrome cobalt alloys.

“The first EP-M650 3D printer arrived a few months ago and we installed it immediately, which has been continuously printing metal parts,” commented a Jingye spokesperson. “Often one part has to be printed for more than ten days. At present, the printing success rate of our large parts is 100%, and there is no waste product.”

Phillips Corporation has become one of the first to invest in a Markforged FX20 3D printer and has invited manufacturers to see the demonstration unit at the firm’s showroom in Colfax, North Carolina. The composite 3D printed is Markforged’s largest to date, sporting a build volume measuring 525 x 400 x 400mm. It’s designed for high-strength end-use parts in industries such as aerospace, defense, automotive, and energy.

“The FX20 is a game changer! It’s bigger, better, faster and stronger. Combining ULTEM™ 9085 Filament with Continuous Fiber Reinforcement will unlock new potential in large format parts,” said John Harrison, Global Director of Additive for Phillips Corporation. “We couldn’t be more pleased to take delivery of one of the first FX20 systems. I can’t wait to show the full capabilities of this printer to our clients.”

Uniformity Labs launches two new stainless steel powders

In the materials space, Uniformity Labs has announced the launch of two new ultra-low porosity stainless steel powders for 3D printing: 316L and 17-4 PH. Once printed, the materials reportedly produce parts with over 99.95% density on average.

316L is an austenitic stainless steel known for its corrosion resistance, flexibility, and excellent mechanical properties at high temperatures. The alloy is suitable for marine, pharmaceutical, petrochemical, food preparation equipment, and medical applications. On the other hand, 17-4 PH is a martensitic precipitation-hardened stainless steel offering corrosion resistance, high strength, and hardness.

“The application of Uniformity 316L and 17-4 PH stainless steel delivers mechanical excellence for our customers who require materials that perform to the highest standard in extreme conditions,” said Uniformity Labs founder and CEO Adam Hopkins. “Our powders deliver superior mechanical properties, surface finish, printing yield, and part reliability, and allow one machine to do the work of several.”

polySpectra launches AR platform for 3D models

Resin developer polySpectra has launched its new polySpectra AR platform, a browser-based augmented reality model viewer that allows users to view their STL files in 3D. Designed to be completely free to use, the software is all about “massless prototyping”: allowing designers to iterate on parts and view them in physical space without even having to 3D print them. As well as saving on time, this cuts material costs and stops the prototypes from ending up in landfills.

Users can make use of QR codes to pass STL files between desktop PCs and their mobile devices. Once the 3D model is loaded in AR, it’s also possible to change the color of the component and share the results with others using a link.

The 3D printed Boxing Hand Grenade

UK-based fitness expert John Docherty has used 3D printing technology to prototype his latest business venture: the Boxing Hand Grenade. The small protective device is intended to provide support and impact absorption when worn under boxing gloves, and is specially designed to fit the contours of the human hand.

To ensure he was first to market with the idea, Docherty employed the help of UK-based 3D printing service provider Protolabs, who helped him 3D print an initial prototype using Stratasys PolyJet technology. The design has since been refined and 3D printed with a lattice structure via Carbon’s DLS process.

Docherty said, “As an entrepreneur with limited resources I needed to find a manufacturing partner that understood what I was trying to create and how important it was to get the product to market before another innovation came to light. Protolabs, alongside TORUS Technology Group, were able to provide us with multiple functional 3D printed prototypes, which allowed us to pressure test and adjust our product.”

Latest awards and grants in additive manufacturing

Youngstown State University, the University of Northern Iowa, and the National Center for Defense Manufacturing and Machining have received $10 million in funding to increase the adoption of advanced manufacturing processes like 3D printing among SMEs in the US. The joint initiative is made possible by U.S. Rep. Tim Ryan, who secured the funding via his seat on the House Defense Subcommittee on Appropriations.

The project will see the partners provide capital support to hundreds of manufacturing businesses each year, along with training and access to facilities, all in a bid to advance several areas of the defense sector’s supply chains and create jobs.

Elsewhere, 3D printing materials provider 6K recently received a $1.5 million Massachusetts Manufacturing Innovation Initiative (M2I2) grant from the Baker-Polito Administration. The firm will use the funds to accelerate the production of its proprietary 3D printing and battery materials using 6K’s UniMelt technology.

“M2I2 allows us to target support toward companies that, like 6K, are committed to growing their operations here in Massachusetts,” said Governor Charlie Baker. “Through this grant we are funding new infrastructure that will lead to job growth and production, but we’re also supporting a game changing, clean technology that promises to revolutionize the supply chain for batteries by keeping more of this production here in the Commonwealth.”

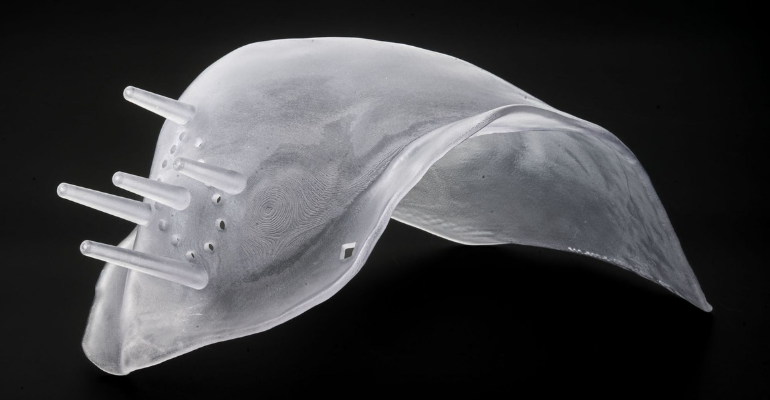

Finally, 3D printing service bureau Custom Prototypes was awarded the “Technical Competition Members Choice Award” for its 3D printed water faucet design at the Additive Manufacturing Users Group (AMUG) Conference earlier this month. The design was 3D printed using Direct Metal Laser Sintering (DMLS) and is lotus-inspired, featuring a complex internal channel structure.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on the 3D printed metal faucet. Photo via Custom Prototypes.