3D printed cameras aren’t a new innovation. From Kickstarters for universal cameras to tiny 3D printed cameras that can fit in syringes, we’ve pretty much seen it all. Except maybe for a completely, 100% 3D printed camera. Using a Form 2 SLA printer, genius Amos Dudley has designed a camera made entirely out of 3D printed parts, including the lens. The analogue camera was designed and made by the 23 year old digital design student in order to preserve older technology by creating it with new technology.

Six revolutions of the indicator is a roll of 24 shots. Image: Amos Dudley

“Analog photography takes the sense of a moment and turns it into a tangible image. My 3D printer turns the content of my thoughts into real shape and form. I wanted to know if there’s a more authentic photograph to be found at the intersection of design and photography – so I set out to make a camera with only a 3D printer,” said Dudley on his blog.

How did he make a fully 3D printed camera?

Dudley began by listing all the components he needed for a functional camera body, and then optimizing the design for printing speed and material usage. He separated the body into modules, so parts like the lens and shutter could be swapped out later for different designs without having to reprint the entire camera.

The design nitty gritty

35mm was the natural choice for film size, as it is the most easily accessible and easiest to get developed. Film is drawn through the camera by a sprocket rod, and then loosely gathered by a secondary takeup spool.

“I work on a Form 2 SLA printer, which draws parts out of laser cured resin. The resins have different material properties, varying in strength and flexibility. Resin parts need to be designed to the right scale to balance friction, mass, and durability. I found that parts printed on the Form 2 need to be designed with ±0.075mm tolerances to reliably fit together, and .25mm clearances to move smoothly in kinetic assemblies. Most resin parts have high friction and need to be well lubricated, or they will quickly wear down.”

Like regular analogue cameras, film is loaded via a door in the back of the 3D printed camera. There are two buttons that manually control shutter speed, and is even capable of doing long exposures.

The lens

Creating a functional lens with a 3D printer was an ambitious goal, as lenses need to be exceptionally smooth in order for light to focus across an imaging plane. To achieve this Dudley printed the lens with transparent resin on an SLA printer, and then put in a lot of post-processing work.

“I started by hand at 400 grit and went up to 12000 grit by increments of 200 and a set of micro-mesh polishing pads. This process took about 5-6 hours per lens and a lot of elbow grease.”

Even then, the results weren’t optically sharp enough to be viable for a camera lens.

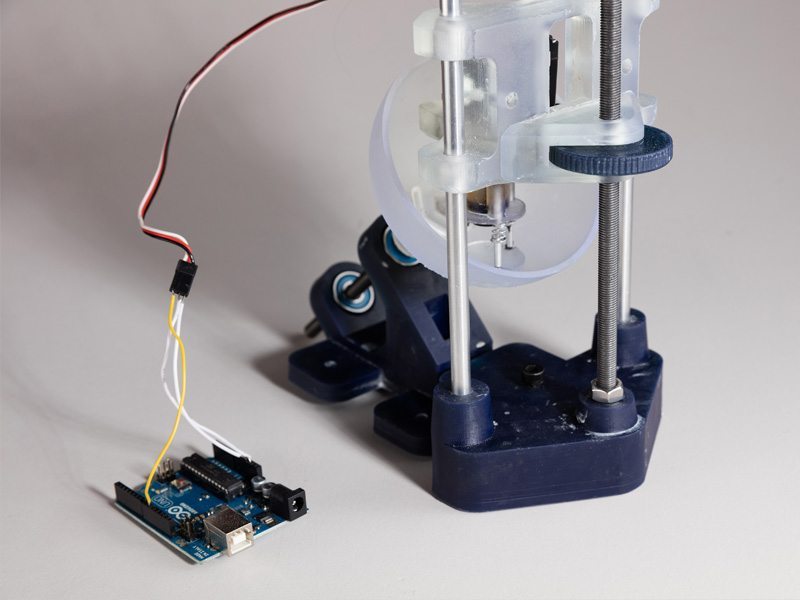

Image: Amos Dudley

“I decided to try a process similar to what’s used in commercial lens making, where a lens is ground against a spherical form (concave or convex) with an abrasive slurry between the two. I prototyped a machine that would do this for me, hopefully removing an even amount of material from the lens in a way that wasn’t possible by hand,” said Dudley.

He then dipped the lens in resin and cured it with UV light to fill in all the microscopic layer valleys. A lot of additional work went into the process of making the lens functional.

After printing a method of testing the focal length of the lens on an Olympus OM-D Micro Four Thirds camera, Dudley’s lens was ready to go.

The shutter

A printed spring “flicked” the cylinder between its two positions. Image: Amos Dudley

Dudley used a gear system instead of the traditional spring system for the shutter, drawing inspiration from a shutter from 1885 with two counter-rotating planes. Two mirror image planes swoop past one another when the shutter button is pushed, moving from blocking the aperture in one position to blocking it in the other. Using Blender’s animation system, Dudley optimized the mechanism for his 3D printed camera.

The only control for the shutter speed is the speed of your own fingers, meaning long exposures could be quite simple but all shots would be estimations in their exposure times.

Image: Amos Dudley

The photos

The resulting images from the 3D printed camera are beautiful, with the spherical lens adding a vignetting to the frame that gives the shots a nostalgic, almost spooky effect.

You can find the 3D files to print your own camera here.

Featured image: Amos Dudley