Glaucoma is a common condition affecting approximately 60.5 million people around the globe. As an irregularity in fluid flowing around the eye it clouds the retina, causing irreversible damage to eyesight and potential blindness.

Using 3D bioprinters, researchers at the Colorado School of Mines have proposed a new method of studying the condition.

A question of pressure

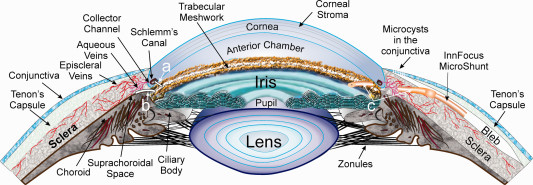

The only way of controlling glaucoma development is through managing the intraocular pressure (IOP) of the eye. IOP is regulated by a layer of cells known as the trabecular meshwork (TM).

Glaucoma occurs when there is a blockage in the TM. Laser eye surgery can be used to relieve this blockage, but it is not always an option for cases further along in development.

Putting a stop to the progress of glaucoma is a more preferable approach.

Another dimension of accuracy

In a study from the Krebs Biochemical Engineering Lab at Mines, researchers propose an method for 3D printing a model of TM.

Conventionally produced, TM models would typically be two-dimensional, oversimplifying the structure of the tissue.

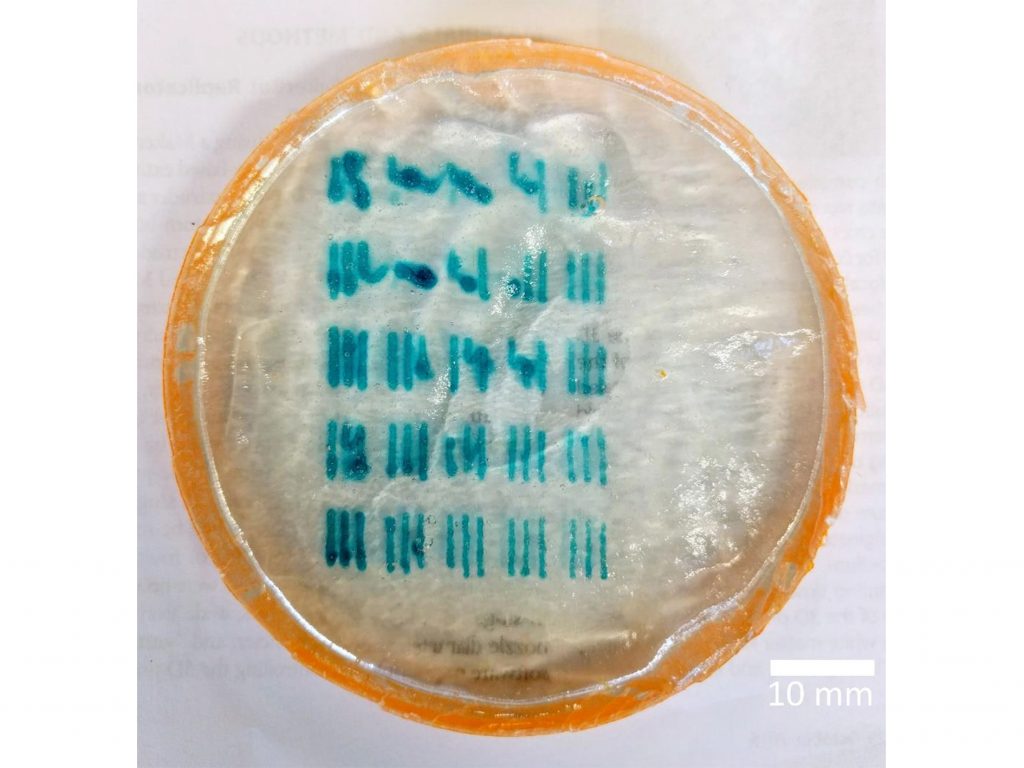

Through calibration of a BioBot Beta 3D printer, the Krebs Lab team determine the optimal settings for depositing high-resolution threads of gel.

The ideal micro-envronment for life

The hydrogel demonstrated in the study is made using extracts of algae.

The material is often used for cell-supportive research due to its shape retaining properties. It can also be combined with upwards of 90% water content, which is the ideal micro environment for growing and maintaining living cells.

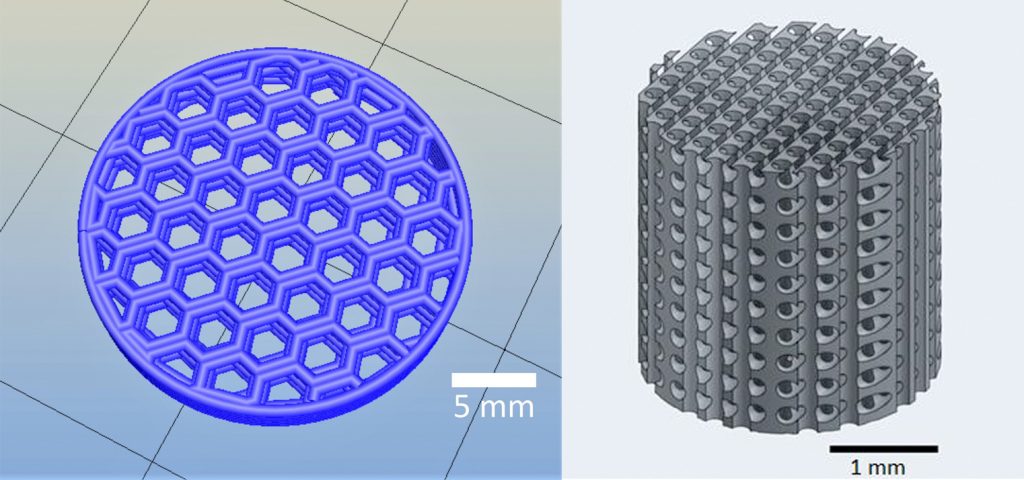

The proposed next step with the gel is to arrange the threads into more complex scaffold structures.

The designs mimic the natural grid structure of body tissue, and so when cells are added they “sort out” into the specified arrangement.

By culturing the cells for a number of days, they could eventually grow into a layer of tissue that could be used in advanced studies of TM, and as a therapeutic treatment.

Further reading

The 3D bioprinted TM at Mines is presented by Raymond Huff, Matthew Osmond and Melissa Krebs in a poster designed for undergraduates of the Polymer Research Experience program.

More information about glaucoma research at the lab, in collaboration with Mina Pantcheva, M.D. at University of Colorado, can be found on the lab’s website.

To receive the latest stories about 3D printing research and more, sign up to the most widely read newsletter in the industry, follow us on Twitter and like us on Facebook.

If you’re planning your next career move, register on our 3D printing jobs site now.

Featured image: 3D bioprinted gel for glaucoma studies at the Colorado School of Mines. Photo via Huff, Osmond and Krebs