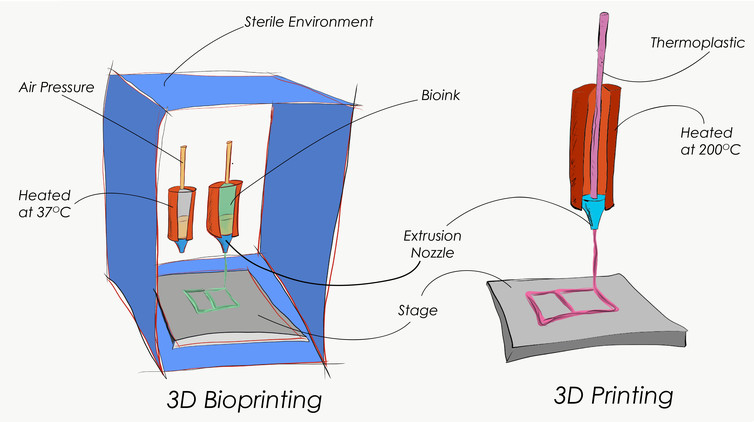

Researchers at Queensland University of Technology (QUT), Australia, argue that 3D bioprinters could lead “the next pharmaceutical revolution”. Eradicating the need for animal testing, and providing humans more reliable and effective drug treatments.

The statement is supported by the team’s recent research, conducted in collaboration with the University of South Australia, University of Freiburg and RWTH Aachen University, Germany.

Clinical failures

In the pharmaceutical industry, only 10 – 15 % of drugs eventually make it to market. The main reason for failure is that drugs don’t pass clinical trails in which humans try the medication.

In preclinical trials animals are often used to test the drugs. Not only is this ineffective when drugs reach the clinical stage, but animal testing has been outlawed throughout the European Union since 2013. So a new, more effective method is required.

Enter 3D bioprinting

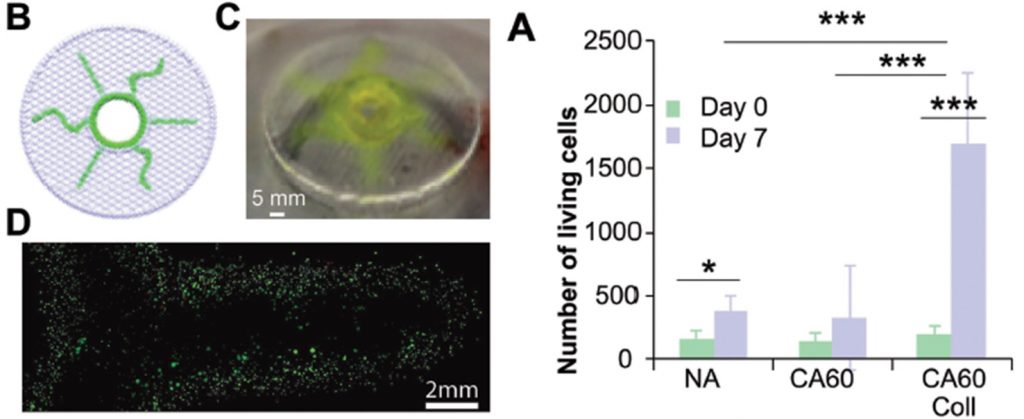

In the QUT & partners study, researchers present a 3D printable bioink that can be tuned to exhibit different mechanical properties, and support the growth of human stem cells.

Multiple mechanical properties are needed to match the environments needed for growing different types of cells, e.g. heart tissue is elastic, the liver is soft and compressible.

Agarose, which is extracted form algae, is used as the base material for QUT’s bioink. The material is commonly used as a support material in stem cell research as it is non-toxic to living organisms, and is the subject of a number of other medical studies previously covered by 3D Printing Industry.

Algae alone is not enough

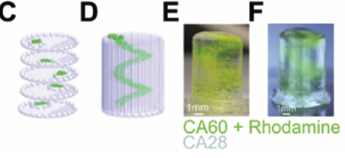

Agarose alone is not tunable to different mechanical properties. To make it so, the researchers add an acidic salt to the material. This material, known as CA throughout the study, is then 3D printed into a cylindrical shape.

A sample of natural agarose is also prepared, and both gels are laced with cells for comparison.

After 7 days in culture, the CA60 Coll 3D printed bioink solution showed the highest rate of proliferation in live cells.

“It’s another step towards being able to print complex, living structures. But it’s not organ transplants we see as the most important possible consequence of this work. There is already evidence that 3D cell printing is a technology useful in drug development, something that may reduce the burden on animals for testing and bring new treatments to market more quickly and safely.”

A paper supporting the research is available for access online in the journal Advanced Healthcare Materials. It is written by Aurelien Forget, Andreas Blaeser, Florian Miessmer, Marius Köpf, Daniela F. Duarte Campos, Nicolas H. Voelcker, Anton Blencowe, Horst Fischer and V. Prasad Shastri.

Looking to hire researchers? Register on our 3D printing jobs site here.

Stay up to date with all the latest 3D printing research news and subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Featured image: Test print of alginate hydrogel with a helical design. Photo via Forget, Heiny, Derme, Mitterberge