Chris Fenton is an electrical engineer who works on supercomputers to pay the bills in New York City. In his spare time, he has created some of the most breathtaking demonstrations of what 3D printing technology is capable of in the hands of a curious and well-trained mind. I wish I had caught his NYC Resistor Class mentioned by Bre Pettis on Twitter.

Besides 3D printing, Chris’s intriguing blog catalogues his various projects such as a 2-Stage Light Gas Gun, an engineering story from his high school days. Apparently, under close adult supervision, Chris altered the design of a typical potato gun into a pickle launcher, capable of exploding a shot of dill 572 mph (and sending PVC shrapnel flying in all directions) In another story, he talks about soldering together a GPS altimeter for the USC Rocket Propulsion Lab two days before launch. He programmed it on his laptop during a car trip out to the launch site on the same day the rocket was set to launch.

Besides his supercomputer revival project, creating homemade speakers, and tackling hardware issues within the growing field of computational genomics, he created this:

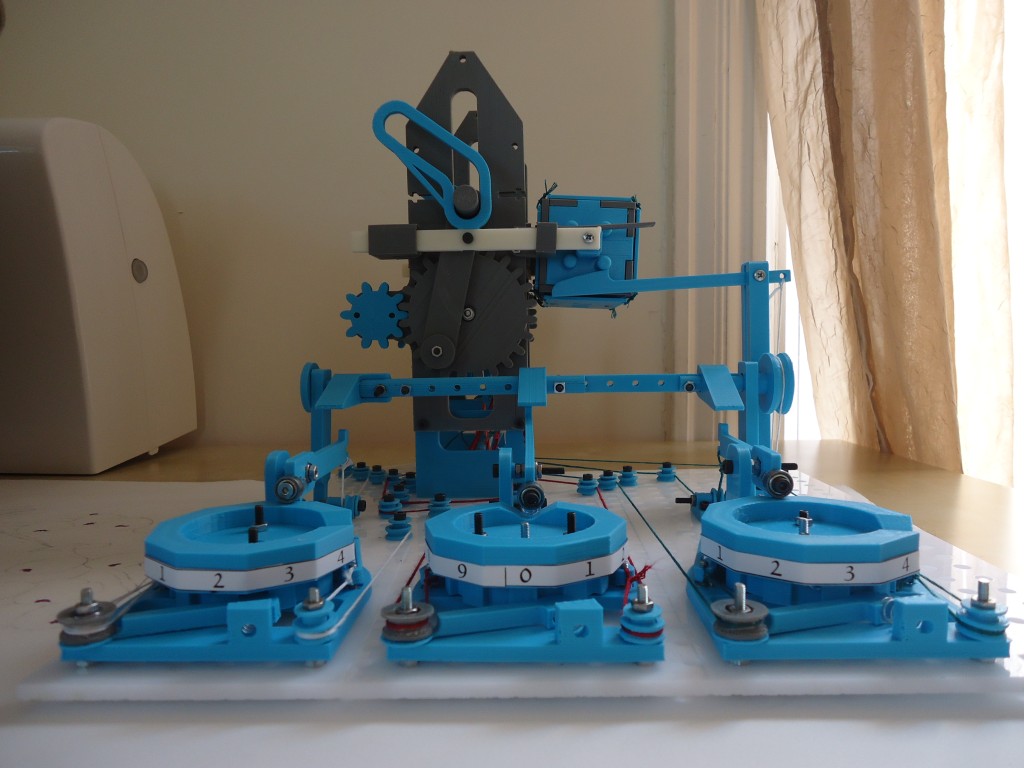

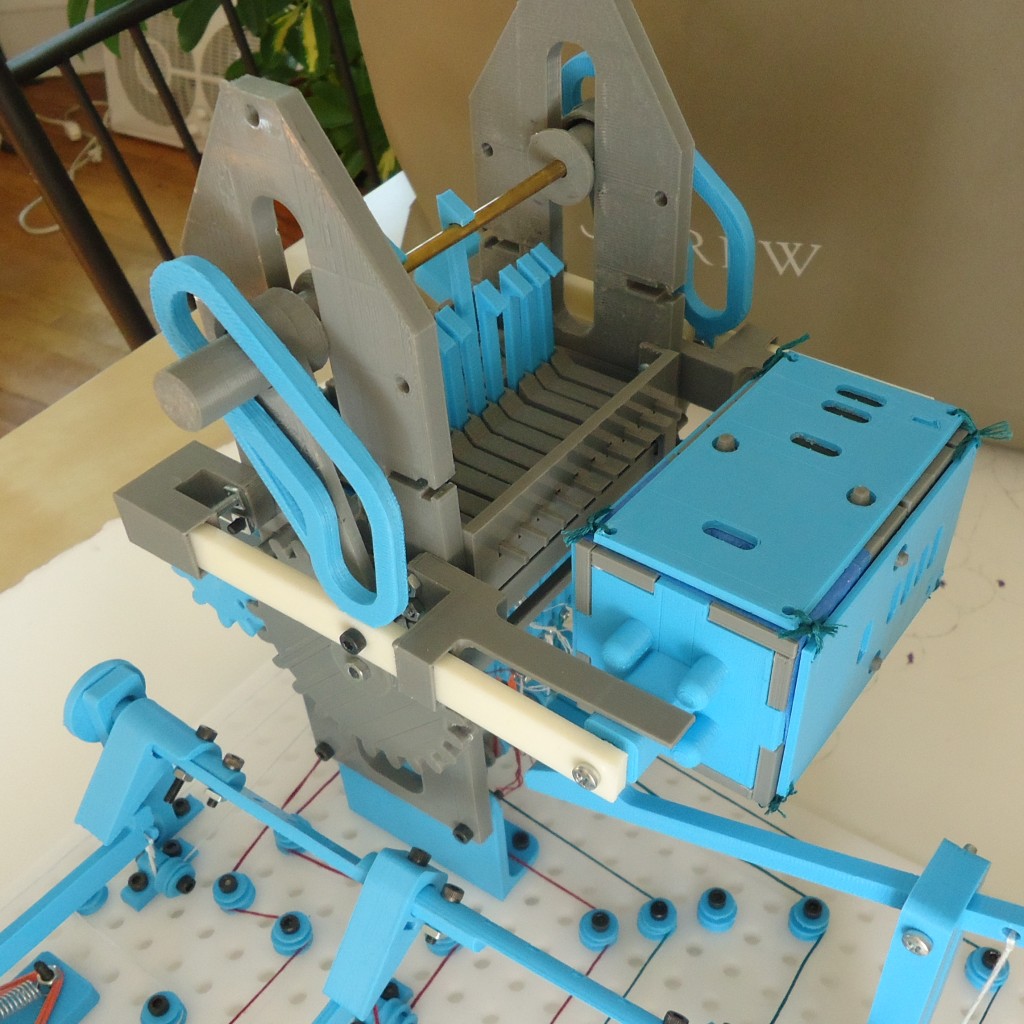

This is an electronics-free mechanical computer that Chris named a “Turbo Entabulator”. Though it doesn’t require any “warm smortch” on its bearings, have any “dingle arms” or require any “borescent skor motion” to operate like the infamous turboencabulator, it did require a lot of time, patience and skill. A mechanical version of his electromechanical FIBAC, the Turbo Entabulator is a successful downgraded (upgraded, depending on how you feel about the use of electricity) version of his “counter-based electromechanical computer idea.”

Constructed entirely from ratchets, pulleys and gears, the idea sprouted from a desire to print a tiny loom after reading The Mechanism of Weaving, by Thomas William Fox. After causing a series of “tiny-industrial accidents”, and perhaps because of the loom’s complicated intermittent (vs. continuous) moving parts, Chris moved on to the Turbo Entabulator.

First, he had to do a few things: Let’s start with writing his own program, 3D printing his own punch cards, creating a counter after 20 tries, expanding the number of hooks in his 3D printable punch card reader from 3 to 10, and adding a crank with a handle to the main drive-shaft (which according to Chris, “vastly improves the ‘user-interface’ of my computer”). He then created a simple counter with a bi-directional ratcheting mechanism set to be used as a base 10 counter. Finally, with the help of his wife, a “librarian extraordinaire and woman of infinite patience”, the Turbo Entabulator was ready for testing.

After computing the first 4 numbers of the Fibonacci sequence, the machine is programmed to continue using the Luhn algorthim, which is also an international standard for validating credit card numbers.

3D printing is quite an incredible technology. The more knowledge, training and creativity you bring to it, the more apparent the scope of its potential truly becomes.

Want to build your own?