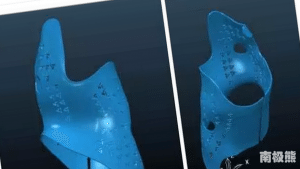

65 year-old Mr. Zhang’ s left hand changed to a clenched fist and couldn’t get back because of his hematencephalon. He couldn’t even hold a paper with this troubled hand. In the rehabilitation department of Zhongda Hospital Southeast University, Mr. Zhang received manipulative therapy and was given a 3D printed brace.

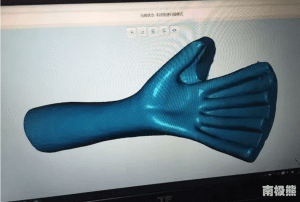

Theoretically speaking, the 3D model is designed according to the limbs’ 3D data scanned by a 3D scanner. What’s amazing about this is that even the test data of the patients’ CT and magnetic resonance could be input to the system in order to make braces with higher precision.

Traditional way of making a brace

The traditional way of making a brace requires several complicated steps. The steps are:

- create a negative plaster

- cast a positive plaster

- revise the positive plaster

- produce a semi-finished production

- fit to patient

- continue to revise until perfect

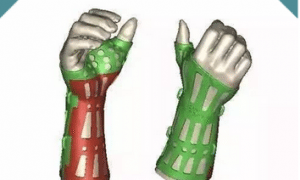

3D printing technology has truly brought a revolution to the traditional brace. Orthopedic doctors have to collaborate with 3D designers to discuss appropriate brace structure and materials.

Traditional technics VS 3D printing technics

- Time: For a Foot Ankle Support Brace, traditional way takes three days while printing only takes six to seven hours.

- Precision: Traditional techniques basically depend on the orthopedist’s manual work, which accompanies some small deviations. A 3D printed brace, however, is produced according to the scanned data, therefore it is much more precise.

- Effect:3D printed braces could fit with affected limb better because doctors know the support strength of different parts.

- Comfort level: During the traditional process, orthopedists would usually make some holes manually on the braces to get air. For a 3D printed brace, designers could design all kinds of holes with different shapes before being formally printed, which would greatly decrease the weight of the brace and makes it more comfortable to wear.

- Appearance: Traditional braces come in a white plastic style with holes. But 3D printed braces come in customizable colors. Designers can even provide children with different cartoon patterns and bring more fun to patients during recovery.

We can expect a whole body customization in 3D printed medical aid in the near future!

Feature image: nanjixiong