Swedish extruder developer Bondtech has released the Direct Drive System (DDS) for CR-10S. Designed as an upgrade to the the print head of the Creality 3D printer, the new DDS extruder combines the Bondtech Mini Geared (BMG) extruder with E3D’s V6 hotend to enable improved extrusion control and reliability on the CR-10S system.

The product was developed with the 3D printing community in mind as Bondtech worked with Greg3D, a maker and 3D printing enthusiast, to design the DDS. The new extruder design was inspired by Greg3D’s own Bondtech BMG + E3D V6 Print Head project aka ‘The Tank’, which he published on Thingiverse in September 2018.

Combined power of E3D V6 and Bondtech BMG

Bondtech’s DDS for CR-10S is supplied as a fully assembled set comprising of an integrated Bondtech BMG and E3D V6 hotend with connection, power cables and sensor holder. The extruder is designed to be ready for plugging in once mounted on the CR-10S for ease of use, with no extra cabling necessary. Designed for use with 1.75 mm filaments, the extruder has also been tested to ensure successful prints with filament from 1.5mm up to 2.0mm, with the aim of providing high reliability regardless of the tolerance of the filament used.

A key feature of DDS is the combination of Bondtech’s Dual-Drive technology on the BMG extruder with the functionality of the V6 All-Metal Hot-End from E3D. Dual-Drive technology prevents the grinding and slipping of filaments to provide reliable and uninterrupted material flow. The gear ratio of 3:1 on the BMG extruder also enables excellent push force with the ability of high resolution 3D printing with small nozzles, or high flow prints with wider nozzles.

V6 hotend functionality allows DDS CR-10S users to reliably print high temperature materials up to 285°C, to the inclusion of soft and flexible filaments. The housing of the DDS for CR-10S extruder is 3D printed in PA12 to provide added strength and effective cooling for the V6 hotend as well.

Popularity of the E3D V6 hotend

The original BMG extruder from Bondtech was released in 2017, initially designed to save users both time and money. At the time of release, Bondtech claimed that the extruder had the best force to weight ratio on the market thanks to the Dual-Drive technology. With the integration of the E3D V6 hotend, Bondtech has now improved its capabilities specifically for the Creality3D CR-10S.

The V6 from E3D has proven to be popular choice of hotend with various manufacturers choosing to integrate it into their 3D printing technologies. For example, Ambots, an Arkansas-based 3D printing technology and assembly provider, has developed a class of mobile robots that incorporate an FDM/FFF 3D printer with an E3D V6 HotEnd. At TCT 2018, FDM 3D printer developer Swiss 3D TEC unveiled the DM3, a 3D printer equipped with the E3D V6 hotend to “ensure the widest selection of compatible nozzles [for] owners of the DM3,” according to Krisjanis Putrins, the Head of Sales at Swiss 3D TEC.

The DDS for CR-10S extruder is available for purchase via Bondtech now for an RRP for $325.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

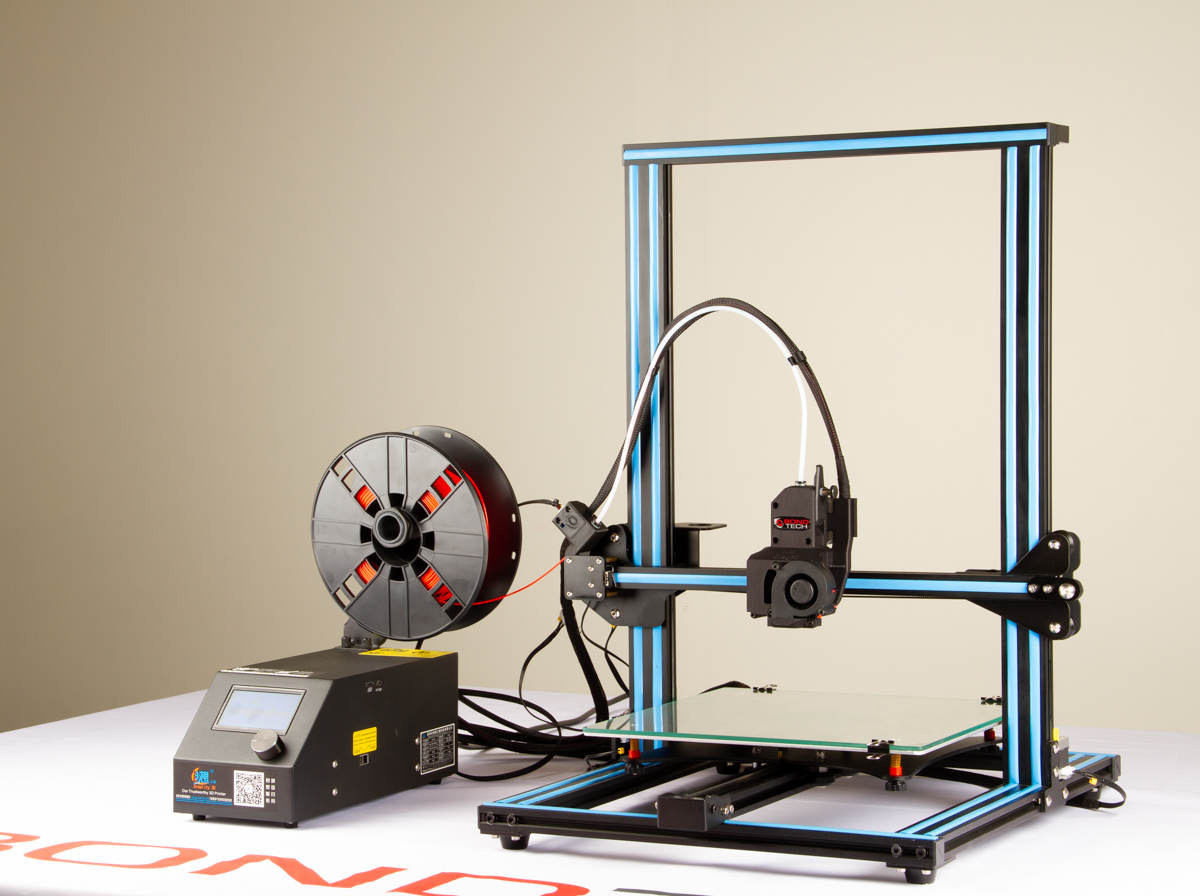

Featured image shows the Direct Drive System extruder upgrade on the Creality CR-10S. Photo via Bondtech.