This week’s edition of Sliced, the 3D Printing Industry news digest features, the first UK conviction for a 3D printing a gun, new bio-printing technology, and growing investment in 3D printed concrete houses in the Arabian peninsula.

We also cover The RESHAPE design competition, PrinterPrezz, GE Additive, NASA and Hawk Ridge Systems.

UK’s first 3D printed gun conviction

A man from Central London has been convicted in the UK for 3D printing a working gun – the first conviction of its kind in the country. The gun, which was capable of firing a deadly shot, was found when police officers searched the home of Tendai Muswere, 26, who initially told officers he was printing the firearm for a university project.

“This conviction, which I believe is the first of its kind relating to the use of a 3D printer to produce a firearm, has prevented a viable gun from getting into the hands of criminals.” said Acting Detective Sergeant Jonathan Roberts of the Metropolitan police, who led the investigation.

In a far less deadly application of 3D printing, German electronic 3D printing company Neotech AMT are set to present “Fully Additive” 3D Printed Electronics at RapidTec. “Fully Additive” refers to the combination of 3D Printed Electronics with classical 3D printing and 3D Pick & Place of Surface Mount Devices. These smart devices contain electronics functionality, both externally and also embedded in the 3D printed body.

Edelkrone, a manufacturer of film equipment has launched a co-manufacturing program called Ortak. As part of the program, Edelkrone provides you with screws/joints/CNC machined aluminum parts that are hard to replicate. Then the company will provide you with an STL file containing the model, which you will manufacture and assemble using your own 3D printer.

The first product in the Ortak program is the Edelkrone FlexTilt Head, a versatile and flexible base plate that you can turn in various directions, which is especially useful when used on top of a slider. The company claims that the design and parts are simple to print and assemble.

Pushing creative and medical boundaries with 3D printing

The RESHAPE design competition, which invites submissions for new solutions in wearable technology and product design using 3D printing and other digital manufacturing technologies, has announced this year’s jury. The panel will include, Behnaz Farahi – Architecture, Fashion and Interaction Designer, Julia Weems – IED Barcelona – Fashion Director and Alberto Lovisetto – Moncler 3D Project Coordinator.

Now in its fifth year, the theme of RESHAPE 19 is ‘Cognified matter’, which challenges makers and designers to create wearable technology and smart products that utilize sustainable models for future applications.

Furthermore, California-based medical 3D printing service bureau PrinterPrezz, has announced the company has achieved ISO 13485:2016 certification for its Quality Management Systems for medical devices.

To be certified, organizations must demonstrate an ability to provide medical devices and related services that meet customer and regulatory requirements. PrinterPrezz has met these standards for its 3D printing of titanium, non-titanium metals and advanced resin and plastic non-active implantable and non-implantable medical devices, and surgical tools.

Adopting the latest 3D printing technology

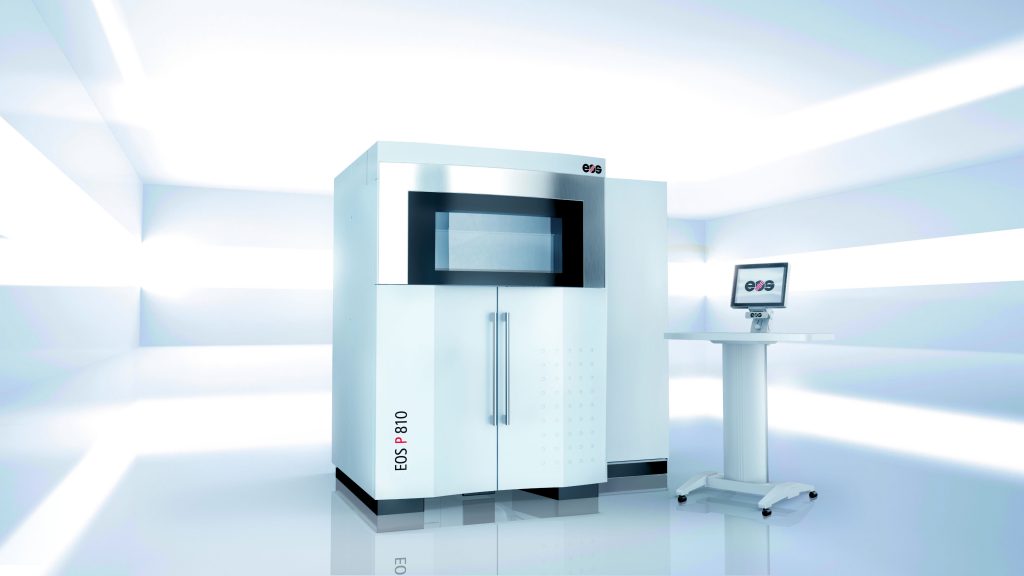

Dedienne Multiplasturgy Group, a French designer and manufacturer of high-performance plastic and composite parts for metal replacement has become the first French manufacturer to install an EOS P 810 laser sintering system. The company will add the machine to produce EOS HT- 23 parts, an EOS powder made from Kepstan PEKK, the extreme polymer supplied by Arkema, and reinforced with carbon fibers.

GE Additive have confirmed that Toulouse-based FusiA Aeroadditive – part of the French group Freyssinet AeroEquipment and the Canadian FusiA Group – will invest in its first GE Additive Concept M2 multilaser system. FusiA Aeroadditive’s customers include Airbus, Bombardier and Safran and it is also closely involved in a number of additive research projects on both sides of the Atlantic.

“As our business scales we have made the strategic decision to transition over to GE Additive technology and invest first of all in a Concept Laser M2 platform,” says Cyrille Chanal, CEO of FusiA Groupe. “Through its own additive journey, GE Additive brings deep experience of the specific needs of the highly-regulated aerospace industry and therefore the demands of our customers for reliable and repeatable technology.”

New developments in hardware and materials

Berlin based developer and builder of 3D scanners, Botspot, has announced the latest member of its botscan 3D Full Body Scanner series at Rapid.Tec. The botscan NEO system produces precise and colorfast 3D data of people and larger objects up to 3.30 meters in diameter. It is also modular and allows for easy transport and modular expandability. The company claims that assembly and disassembly takes less than one hour each. The botscan NEO will be available for the general public by autumn 2019.

In related news, Korean biotechnology company T&R Biofab has announced that it has registered a patent for a multiple nozzle 3D printing system along with a new 3D bio-printing technique. The technology uses multiple nozzles simultaneously to speed up 3D printing, the nozzles themselves have a wide range of movements that enable them to make more accurate three-dimensional printing. The multi-nozzle technology enhances the viability of fabricated cells and helps to form complex cell structures in a shorter time frame.

“By utilizing this patented technology, we will continue to research, develop and commercialize organoid, organ on a chip, and artificial tissue and organ,” the company said. “We expect that the new patented technology will contribute to the advance of medical technology.”

Supplier of filaments FormFutura has announced that its filaments up to one kilogram will be spooled onto fully recyclable, sturdy cardboard spools. The boxes these new spools come in will also be made out of cardboard.

Aerospace and 3D printing

Tethers Unlimited, an American aerospace company headquartered near Seattle, Washington, has won five NASA awards to develop new types of space appliances. It forms part of $45.4 million NASA prize fund, awarded to over 363 aerospace projects proposed by small businesses and research institutions.

One of these appliances is the Resin Additive Manufacturing Processed Thermal Protection System (RAMP TPS), an in-situ cured, additively manufactured, spacecraft heat shield material and process. RAMP TPS will enable low-cost production of heat shields for re-entry vehicles.

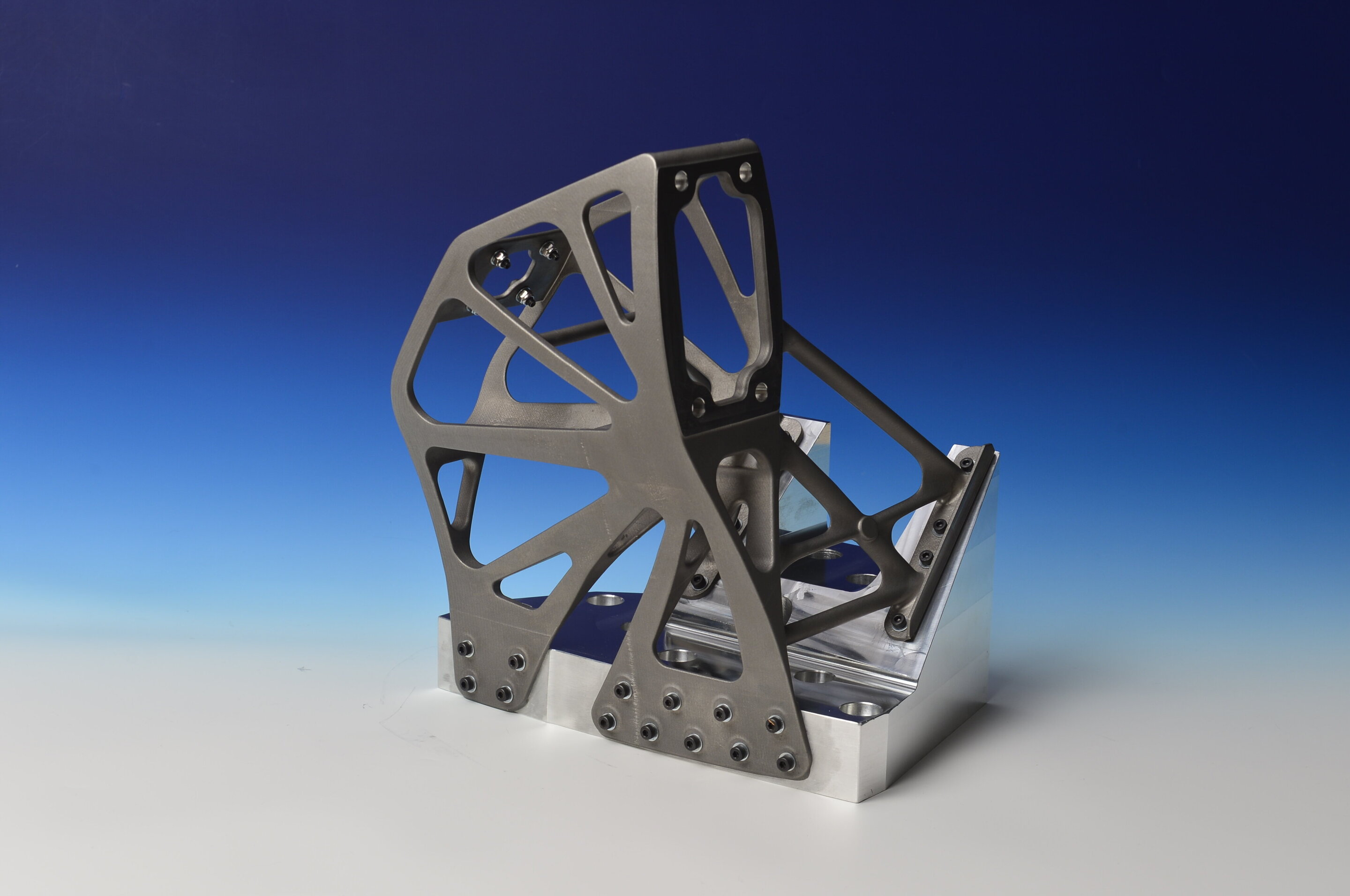

In other aerospace news, the Ariane 5 expendable heavy-lift rocket, designed by the French government space agency Centre national d’études spatiales (CNES), will use a 3D printed titanium alloy bracket. The bracket is 30% lighter that the original version currently in use, serving to support the cryogenic fuel tank of Ariane 5’s upper stage. To create the lighter part, the instrument’s design requirements put through “topology optimisation” software, which formulated the best possible shape.

Opening new 3D printing factories and facilities

Hawk Ridge Systems, a Silicon Valley-based reseller of 3D design and manufacturing solutions, has announced the opening of a new additive manufacturing facility in Ohio. The new facility, which will be opening its doors this month, will provide an environment for client meetings and training sessions as well as a production showroom that will showcase product portfolios from leading AM companies HP and Markforged.

Saudi Arabia’s Al Kathiri Holding Co has secured a $9 million loan by the Saudi Industrial Development Fund for the construction of 3D printed concrete slab-making factory. The facility will produce reinforced polystyrene sheets reinforced with iron and concrete for the building of homes. The factory is expected to produce enough material for the building of 1,000 homes each year. The plant is expected to be established and start production in 2020, and is expected to deliver cost and time savings of 30%.

Finally, the Additive Manufacturing Users Group (AMUG), an organization that educates and advances the uses and applications of additive manufacturing, has presented Elizabeth Goode with its President’s Award. Goode, the eighth to receive this prestigious award, is an additive manufacturing veteran and owner of Goode Ink, which provides consulting services for marketing and strategy. This also means she now holds two of AMUG’s highest recognitions, having been presented with a Distinguished INnovator Operator (DINO) Award in 2016.

Subscribe to the 3D Printing Industry newsletter and follow us on Facebook and Twitter for the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find new opportunities in the 3D printing industry.

Featured image shows Sliced logo edited on to Edelkrone’s 3D printed base plate. Photo via Edelkrone.