Nicholas Manousos is a horologist, a studier of the measurement of time. He is also a computer scientist and engineer. With all of those interests combined, Manousos is fascinated with the beauty of mechanical objects. The tourbillon, in the engineer’s mind, is the “ultimate expression of mechanical beauty“, a device invented at the end of the 18th Century, by Abraham-Louis Breguet, to prevent the effects of gravity on a watch’s escapement and improve the timepiece’s accuracy. Though the device hasn’t been proven conclusively to serve its intended function, Wikipedia explains that it is “still included in some expensive modern watches as a novelty and demonstration of watchmaking virtuosity.”

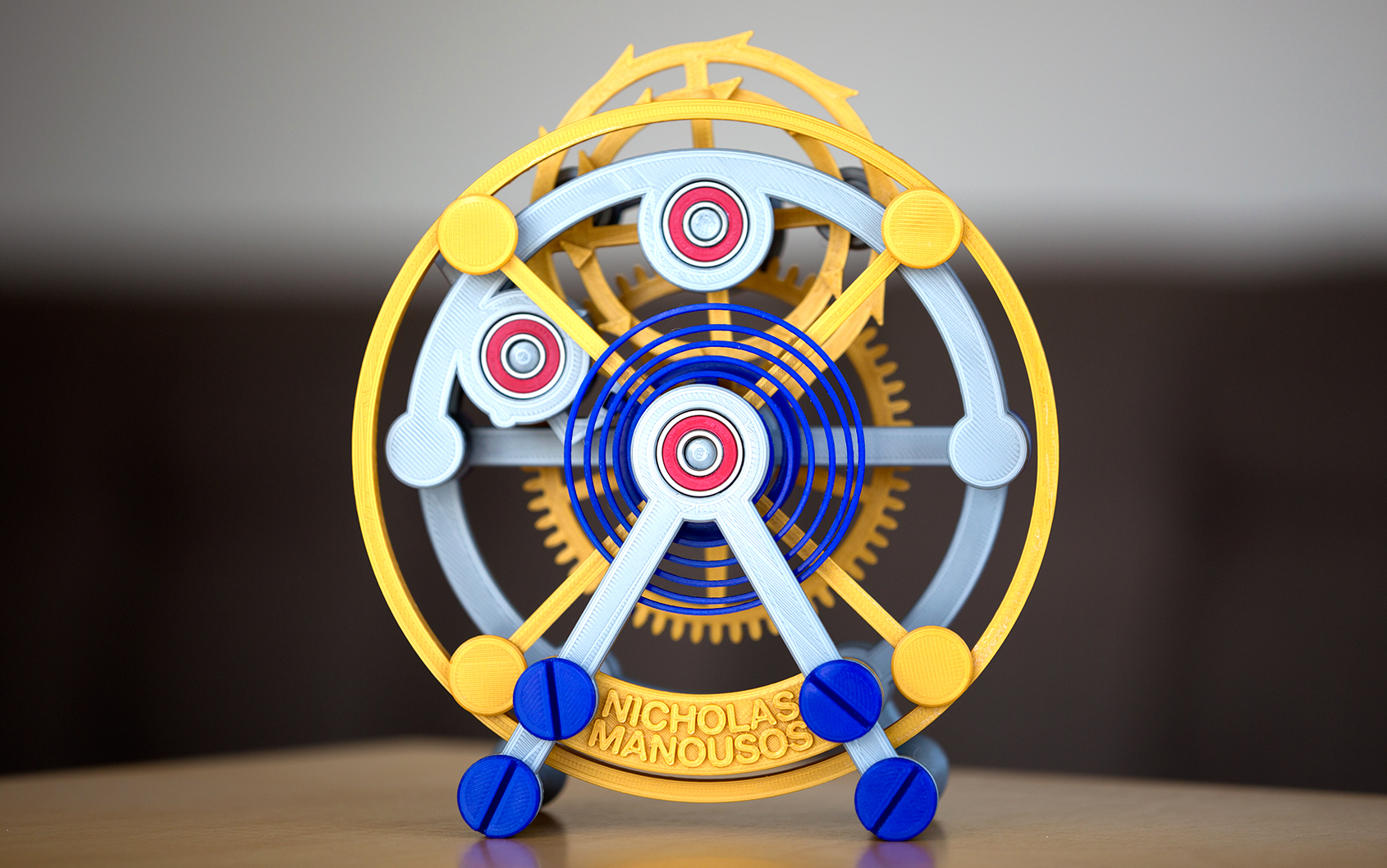

Normally, Manousos admits, a tourbillion is much too delicate for someone to handle and truly appreciate the mechanics. With 3D printing, however, the horologist has blown up the exquisite mechanism for all to admire with Tourbillon 1000%. Made over the course of three years, Tourbillon 1000% is not meant to be a timekeeping apparatus, but instead acts as an educational device. The piece is a variation on the Co-Axial Escapement design by horologist George Daniels and is 3D printed in PLA with 200 micron layer resolution on a delta-style 3D printer. Everything except for the device’s ball bearings are 3D printed. Watch the Tourbillon 1000% in a slick promo video below:

Or, if you’d prefer a more realistic depiction, free from the magic of movie making, watch the timepiece click away in this video:

As all of Manousos’s tourbillons are printed, assembled and calibrated in-house, the only way to get your hands on one is by contacting the artist and horologist directly. This also means that his orders are open for customization. To purchase one, customized or not, contact Manousos here.