Using Ultra Solid filament developed by local manufacturer MyMat Solutions, a group of researchers from the EHU/UPV (Basque Country University), together with BIOEF, Hospital of Cruces, and Leartiker Polymer Institute have lowered the cost to 3D print a low-cost bioreactor that can stand sterilization temperatures higher than 100ºC during a 4-hour process.

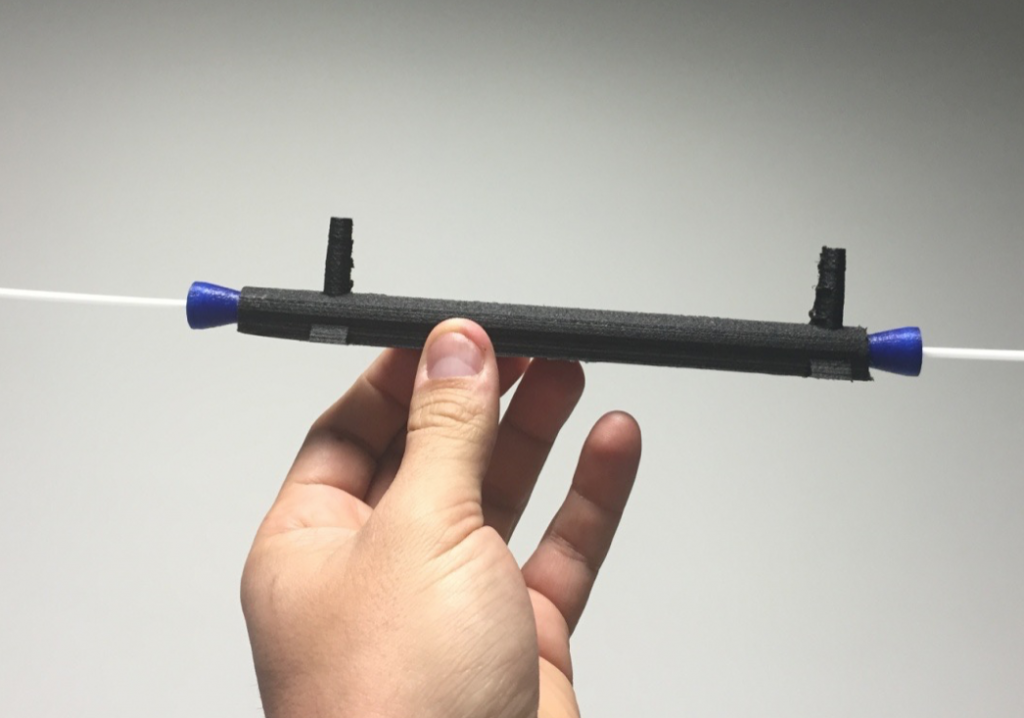

The project’s main aim is the analysis and testing of novel compositions of medical grade tubes used in cardiac applications. The tube is positioned inside the bioreactor and a continuous flow of different liquid compounds – that is inserted and extracted from the upper side of the bioreactor – is forced to flow in the outer layer of the tube. After the tube has been exposed to the liquids, it is analyzed for contamination.

The geometry used for this project purpose has been designed by Leartiker experts following the recommendations offered by the other two parties involved in the project. Hospital of Cruces, BIOEF and EHU/UPV analyzed the contamination of the tested tubes in order to develop tubes with improved behavior. The implementation of such low-cost, locally manufactured approaches to these kind of technology solutions allow scientists to significantly reduce both the cost of research and the testing time requirements. While this specific project makes no reference yet to open source availability of the 3D printable bioreactor, the sharing of the designs can contribute to further reduce costs while increasing the speed of technological development.

Experiments such as this this demonstrate beyond doubt that the potential for combining 3D printing and materials knowledge in order to answer the the requirements of professionals in the medical and other sectors is truly endless. The real question is, why aren’t there even more such applications yet?