3D printing is advancing agriculture and may change how crops are harvested. On the anniversary of the fall of the Berlin Wall (9th November) forward thinking individuals gathered in Berlin to evaluate future global challenges. At the conference earlier this month, a talk by the Australian Centre for Field Robotics (ACFR) addressed the future of technology in agriculture. Salah Sukkarieh, director of research and innovation at ACFR led a talk discussing the influence of robots on farming techniques,

We are starting to see more and more robots on the farm, doing farm tasks and eventually, we are going to get to the stage where you see semi-automated or even fully automated farms happening.

RIPPA, pictured below, is one such example. The robot is solar powered and designed to work for long hours in the field. The robot’s name stands for ‘Robot for Intelligent Perception and Precision Application’ apt for its variety of sensors, and a nice hat-tip to its country of origin. The RIPPA can be complimented with the VIIPA, Variable Injection Intelligent Precision Applicator, in order to distribute liquid around a farm. Responding to Australia’s House of Representatives Standing Committee on Agriculture and Industry Professor Sukkarieh explained how additive manufacturing plays a role in this project,

Various unmanned air, ground and marine based robotic platforms will be more readily developed, demonstrated and commercialised for use in agriculture that will be spurred by the rapid acceptance of 3D printing and optimisation software.

3D printing food

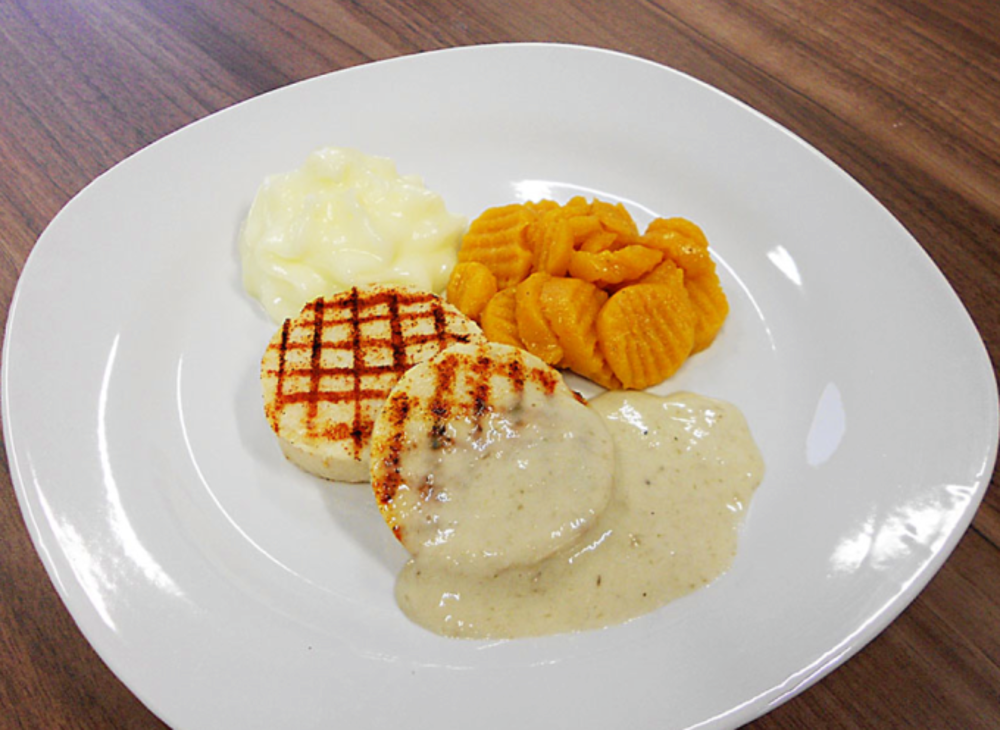

In addition to robots being used in farming, this week also brings news of 3D printings application to food processing. As previously reported by 3DPI, Germany’s Biozoon have 3D printed ‘Smoothfood’ to help feed the elderly. Developed for those who are unable to chew food properly, this process involves mixing food with an texturizing agent before 3D printing into a desirable shape and soft texture. This is advantageous as it can motivate those who have lost their appetite to eat, and the 3D printing process allows a higher number of meals to be prepared than a chef would otherwise have time to make.

Now Australia’s Meat and Livestock Australia (MLA) have picked up on this idea and are planning to 3D print red meat in an effort to: reduce waste, increase value of off-cuts, and reduce processing costs.

Furthermore we recently saw how additive manufacturing could be used to help remote farmers access technological advancements. 3D printing spare parts for their machinery could be a possibility for farmers in remote areas potentially solving logistical issues. In the long term this aspect of 3D printing as it relates to food may yield much wider benefits.

Featured image shows a 2D printer printing a steak, this is an unlikely vision of the future of 3D printing and food. Image from FreeRepublic.