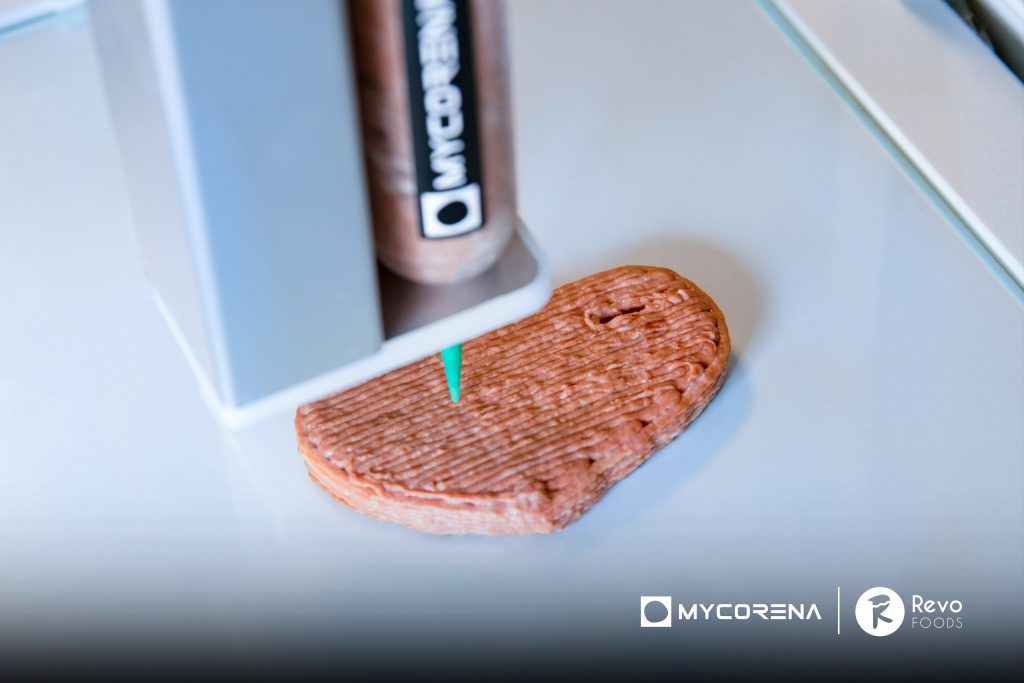

The 3D printable mycoprotein will have a mild flavor, light color, and soft fibrous texture, making it especially appropriate for seafood substitutes.

Mycorena, a Swedish mycoprotein manufacturer, and Revo Foods, an Austrian 3D food printing pioneer, are working together on 3D printed food. A collaborative research project will examine whether Mycorena’s previously developed and adapted mycoprotein would be better used for 3D food printing. The main aim of this research is to focus on vegan substitutes for seafood and whole-cut products. Here, the objective is the reduction of disparity between animal and vegan products and plant-based or vegan substitutes, resulting in a greater market acceptance of meat substitutes. A brand-new realistic meat-like product category can be developed by combining the meat-like characteristics of mycoprotein with the unconstrained shape capabilities of 3D food printing.

“We have always been interested in food 3D printing and saw that creating a printable mycelium material would probably open doors to creating amazing, unique products. With this technology, the possibilities for texture and form are on another level compared to current meat analogs, being restricted only by imagination, not processing methods,” said Paulo Teixeira, CIO at Mycorena.

“With this new collaboration with Mycorena, we see huge potential to develop the printable mycoprotein further, which can lift meat/seafood alternatives to the next quality level, necessary for large-scale consumer adoption,” says Robin Simsa, CEO at Revo Foods.

What is mycoprotein? (and why 3D print it)

Mycoprotein was created by Lord Rank, the chairman of the Rank Hovis McDougall (RHM) group of businesses, which also produced a lot of starch as a byproduct. The 1960s saw the beginning of the search for an organism that could turn starch into protein more effectively than meat production. Initially, Fusarium venenatum was mistaken for Fusarium graminearum. This bacterium outperformed all competitors and developed into a protein production powerhouse. A savory pie introduced by J Sainsbury was the first item to appear on store shelves under the brand name Quorn.

In vats, glucose syrup is used to feed the fungus as it grows. The growing media is poured into a fermentation vat, which is subsequently sporulated with the fungi. The F. venenatum culture respires aerobically, thus oxygen is fed to it and carbon dioxide is removed from the vat in order for it to grow at the fastest possible rate. Nitrogen (in the form of ammonia) and the vitamins and minerals required to sustain growth are added to create protein. The temperature in the vat is kept constant and is ideal for the growth of the fungus, which may double its mass every five hours.

The growth media is removed from the fermenter through a tap at the bottom whenever the desired quantity of mycoprotein has been produced. It is isolated and purified from the mycoprotein. It has a light mushroom flavor and is a pale yellow solid. The mycoprotein can be varied by adding various flavors and tastes.

After 1,000 to 1,200 hours of development, F. venenatum develops a repeatable mutation that significantly shortens the organism’s hypha length, which is thought to be unfavorable for production. This mutant strain will quickly supplant the parent strain in normal circumstances. The mutant strain can’t take over the product, but it can still grow if the nitrogen supply is changed from ammonia to nitrate or if peptone is added to ammonium cultures. Alternately, selection forces like food concentrations or pH levels can postpone the emergence of the mutant.

3D food printing

The rheological and printability features of nutrient-rich 3D printed foods are being studied by researchers from the US and Mexico. Target populations could be given the precise nutrition they require with the help of 3D-printed food products. However, printed formulations made of fruits, vegetables, grains, and possibly even animal products are required for personalized nutrition to meet a wide range of needs based on a balanced diet. In the current investigation, the research group created a number of nutritional printing formulas with up to nine distinct components, including sustainable proteins like insect flour and waste goods like orange peel.

Elsewhere, in an opportunity to invite proposals for a new edible 3D printing material, the Defense Advanced Research Projects Agency (DARPA) issued a Small Business Innovation Research (SBIR). The concept call focused on the Innovative Nutritional Formulations SBIR Program, which intends to draw creative suggestions for transforming biomass (produced by DARPA’s ReSource program) into secure and palatable food items. The cellular biomass formulations can be in the form of a liquid, solid, powder, paste, or ink, as long as they are compatible with at least one type of 3D printing technology, according to the Agency. These edible materials are intended to be utilized in battle zones and other disaster areas where soldiers and people would not have easy access to traditional meals.

Nominations for the 3D Printing Industry Awards 2022 have now commenced. Who do you think should make it to the shortlists for this year’s show? Nominate now, the form closes at the end of the month.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.