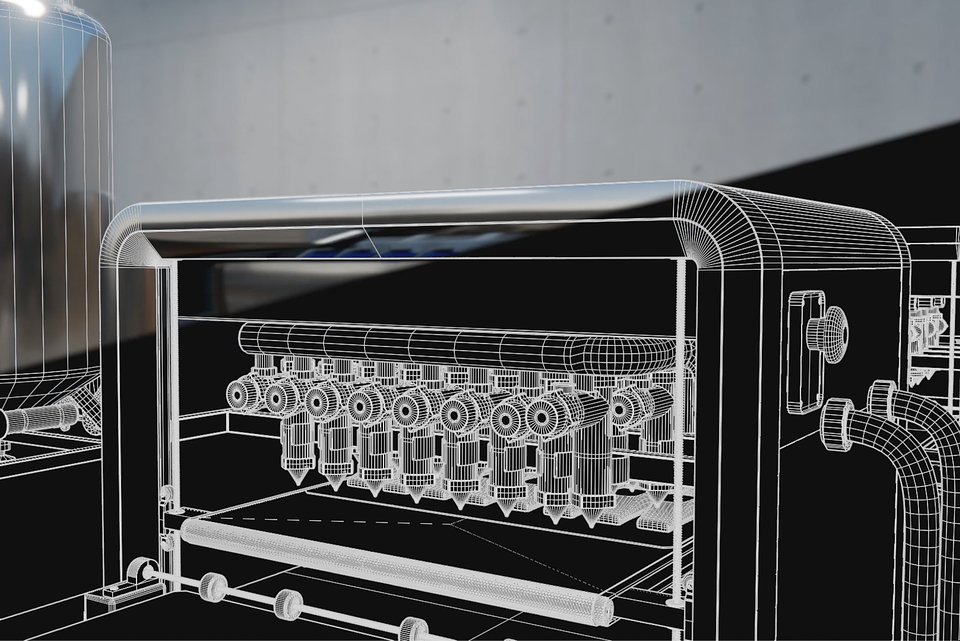

Austrian food-tech company Revo Foods has launched the Food Fabricator X2, a new high-throughput food 3D printer. According to the company, this is the ‘world’s first industrial production method for 3D printed foods.’

The Food Fabricator X2 reportedly offers high-volume production of a range of whole-cut meat alternatives and other food products possessing customized shapes, structures and textures.

Revo Foods has also announced efforts to scale up its production capabilities. To achieve this, the company has announced a public investment opportunity, making digital shares available to purchase. Open until April 18, 2024, the capital raised will be used to upscale the company over the next two years. Two additional major upscaling steps will then follow, beginning in 2026.

“3D food printing on an industrial level allows us to change the way we think about food. Products that were previously very exclusive and more likely to be found in gourmet restaurants can now be produced on a large scale,” commented Revo Foods CEO Dr Robin Simsa.

“I am excited about the new creative opportunities that open up to food product developers with the help of this technology.”

Food Fabricator X2: ‘industrial-scale food 3D printing.’

Revo Foods traces its origins to a 2017 EU-based additive manufacturing research project by a group of international students. This team subsequently developed a novel extrusion-based 3D printing process for producing salmon, under the trading name Legendary Vish. Since rebranding to Revo Foods, the company has upscaled production, and now sells its 3D printed meat substitutes in supermarkets.

The company’s products have been developed to overcome global environmental challenges, offering a sustainable alternative to traditional food production and procurement methods.

According to Revo Foods, 90% of fish species are on the verge of exploitation, 30% of which are currently being overfished. What’s more, high toxin and microplastic levels in conventional fish products, as well as marine ecosystem destabilization, are reportedly leading to distinct changes in the $400 billion fish market.

To capitalize on this shift, the company’s novel technology fabricates fish and meat alternatives at large volumes. In September 2023 the company launched “THE FILET – Inspired by Salmon” proof of concept, 3D printed with the Food Fabricator X1. This 3D printed salmon filet alternative, based on mycoprotein, was the first 3D printed food product to be sold in supermarkets.

The company’s latest food 3D printer, the Food Fabricator X2, features a multi-nozzle 3D printing system, allowing for continuous food production. According to Revo Foods, this marks the first time that mass production is possible with food 3D printing technology.

This new 3D printer also features a high-precision extrusion system, allowing multiple ingredients to be combined in any predefined structure. As such, novel foods such as authentic meat alternatives and products with innovative structures, shapes or textures can be produced at large scale.

The company also claims that its new offering enables ‘mass customization’ of food production, facilitating flexible control of size, shape, materials and texture, without making major hardware adjustments during 3D printing.

Is 3D printed food the future?

Food 3D printing offers notable sustainability benefits by producing realistic, meat alternatives. Revo Foods is not the only company to offer 3D printed food options. Redefine Meat, a food 3D printing firm, also offers commercially available 3D printed animal-free meat.

In 2020, the company unveiled Alt-Steak, its first 3D printed plant-based product. Predicted using the company’s proprietary food 3D printers, Redefine Meat claims that its meat alternative is 95% more sustainable than its conventional counterpart.

The company has also rolled out its range of New-Meat 3D printed food products to restaurants and hotels in Israel. This plant-based portfolio includes 3D-printed hamburgers, sausages, lamb kebabs, Middle Eastern ‘cigars,’ and ground beef.

“We’ve achieved a level of superiority in taste and texture that surprised even some of the most recognized chefs in the world, and our unique technological capabilities enable us to replace every part of the cow for the first time,” commented Ben-Shitrit, CEO and Co-founder of Redefine Meat.

Elsewhere, China-based 3D printer manufacturer offers the Wiiboox food 3D printing extruder, which can be integrated into a range of standard desktop 3D printers. A cost effective alternative to pricey food 3D printers, the LuckyBot retails at just $159, and can extrude chocolate, peanut butter, cream, cheese, jam, mashed potatoes, salad dressing, and other soft foods. The extruder can fabricate both 2D and 3D custom food designs, and is targeted towards coffee and dessert businesses, chefs, and bakers.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Revo Foods’ 3D printed salmon on the Food Fabricator X2 production line. Image via Revo Foods.