Cimatron, a leading provider of CAD/CAM solutions has accounced that it’s next software release will support the Additive Manufacturing File (AMF) format — a format adopted as an industry standard by both ASTM International and the International Organization for Standardization (ISO) last year. AMF is an XML-based format designed to allow any computer-aided design software to describe the shape and composition of any 3D object to be fabricated on any 3D printer. Unlike the STL format, AMF includes native support for colour, materials, lattices and more.

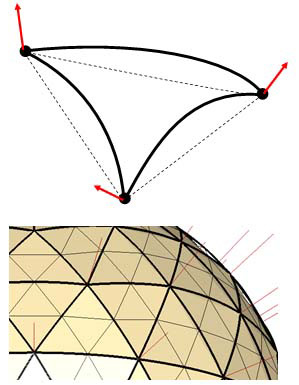

The STL file format remains the dominant file format for converting 3D data for 3D printing hardware, since its origins lie with the development of stereolithography back in the 1980s. However, since 3D printing (additive manufacturing) technology has evolved from producing primarily homogenous shapes in a single-material to multi-material geometries in full colour and graded materials there has been a growing need for a new standard interchange file format. A second factor that has ushered the development of the standard is the improving resolution of 3D printing technologies. Now that the fidelity of 3D printing processes have approached micron scale resolution, the number of triangles required to render a smooth curved surfaces results in huge, increasingly impractical, file sizes.

Rachel covered AMF’s progress here for further development history.

Software developers have been reticent, to say the least, in jumping on board, but Cimatron is now putting its head above the parapet. Cimatron‘s President and CEO, Danny Haran, noted: “As we’ve previously stated, we keep looking at solutions that Cimatron can offer to the growing market for additive and hybrid manufacturing. We are pleased to be among the first CAD vendors to offer direct support of AMF. We believe more market participants will adopt AMF as their preferred method of 3D printing file interface in the coming years.”

Terry Wohlers, Wohlers Associates’ president and member of Cimatron’s 3D Printing Advisory Board stated: “Since the late 1980s, the STL file format has been the de facto industry standard for transferring CAD data to additive manufacturing equipment (3D printers). However, the STL format has no provisions for representing colour, textures, materials, lattice/mesh structures, units, and other properties of the finished printed part. The new XML-based AMF standard was developed to bridge the gap between CAD and modern additive manufacturing technology. This file format contains all relevant information required for making a 3D printed part, including the final part’s material, colour and internal structure.’

With more than 30 years of experience and more than 40,000 installations worldwide, Cimatron is a leading provider of integrated, CAD/CAM software solutions for mould, tool and die makers as well as manufacturers of discrete parts and therefore well placed to offer a wide user base the utilities of the AMF format.

It will be very interesting to see when and if other leading CAD/CAM suppliers follow.